Minitype swirl premixed regenerative catalytic combustion reactor

A catalytic combustion and regenerative technology, applied in the field of reactors, can solve the problems of insufficient gas premixing, insufficient reaction, complex reactor structure, etc., so as to increase the premixing effect, increase the surface area of the catalytic wall, reduce the Effects of Ignition Difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

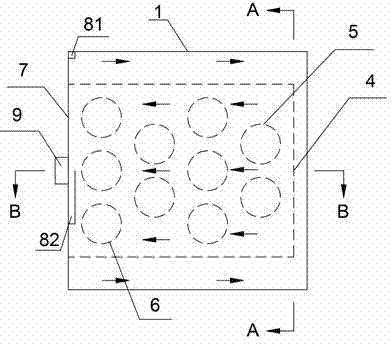

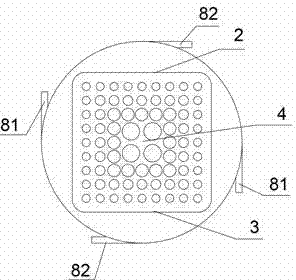

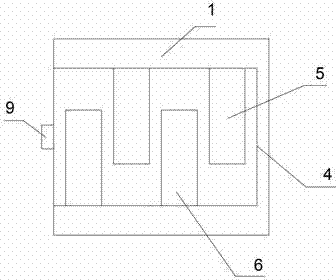

[0023] Such as figure 1 , 2 , 3, and 4, the swirl premixed regenerative miniature catalytic combustion reactor includes an outer cylinder 1, an upper panel 2, a porous panel 4 and a U-shaped panel 3 with a U-shaped cross section.

[0024] The upper panel 2 is set at the top opening of the U-shaped panel 3. The upper panel 2 and the U-shaped panel 3 form a cavity with a rectangular cross section. Flow resistance, the porous panel 4 is set at one end of the cavity, there are many circular holes of different sizes on the porous panel 4, the aperture of the porous panel 4 gradually increases from the surrounding to the middle, and the change of the aperture can effectively adjust the gas density in different parts of the combustion chamber The inhomogeneity reduces the adverse effect on combustion caused by the uneven gas flow rate. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com