Bamboo charcoal Lyocell fiber and preparation process thereof

A preparation process, bamboo charcoal technology, applied in the direction of fibrous filler, fiber chemical characteristics, artificial filament in cellulose solution, etc., to achieve uniform distribution of moisture absorption and dehumidification performance, simplify solvent recovery method, and reduce recovery investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

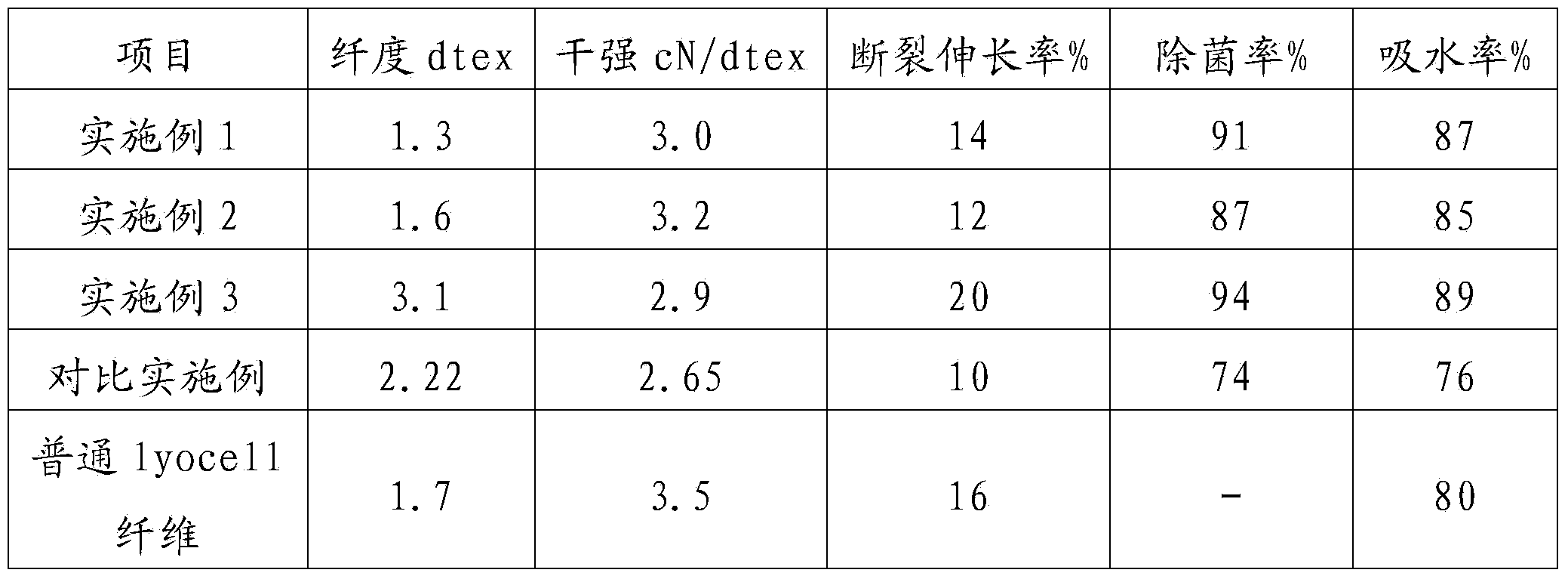

Examples

Embodiment 1

[0031] A kind of preparation technology of bamboo charcoal Lyocell fiber, step is as follows:

[0032] (1) Bamboo charcoal purification and surface modification: Take 10g of bamboo charcoal material, grind the bamboo charcoal material to the nanometer level, the particle size is 50nm, add the nano-bamboo charcoal to the nitric acid solution of 3mol / , wherein the bamboo charcoal is 15% of the solution mass, in Reflux at 60°C for 30 hours, then repeatedly wash with deionized water until neutral, dry the bamboo charcoal in a vacuum oven at 120°C for 2 hours, then grind the dried bamboo charcoal and add it to 7mol / L ammonia solution , wherein the bamboo charcoal is 20% of the solution mass, shaken at a constant temperature in a constant temperature oscillator at 40°C for 3 hours, then repeatedly washed with deionized water until neutral, and then vacuum-dried the bamboo charcoal in a vacuum oven at 80°C for 6 hours;

[0033] (2) Grind the bamboo charcoal material prepared in step ...

Embodiment 2

[0039] A kind of preparation technology of bamboo charcoal Lyocell fiber, step is as follows:

[0040] (1) Bamboo charcoal purification and surface modification: Grind the bamboo charcoal material to the nanometer level, the particle size is 200nm, add the nano-bamboo charcoal to the nitric acid solution of 8mol / , wherein the bamboo charcoal is 30% of the solution mass, and reflux at 90°C for 10 hours, and then repeatedly washed with deionized water until neutral, the bamboo charcoal was vacuum-dried in a vacuum oven at 80°C for 6 hours, and then the dried bamboo charcoal was ground and added to a 4mol / L ammonia solution, wherein the bamboo charcoal was a solution 40% of the mass, shake at a constant temperature in a constant temperature oscillator at 70°C for 8 hours, then repeatedly wash with deionized water until neutral, and then dry the bamboo charcoal in a vacuum oven at 120°C for 2 hours in vacuum;

[0041] (2) Grind the bamboo charcoal material prepared in step (1) aga...

Embodiment 3

[0047] A kind of preparation technology of bamboo charcoal Lyocell fiber, step is as follows:

[0048] (1) Bamboo charcoal purification and surface modification: Grind the bamboo charcoal material to the nanometer level, the particle size is 150nm, add the nano-bamboo charcoal to the nitric acid solution of 5mol / , wherein the bamboo charcoal is 23% of the solution mass, and reflux at 75°C for 20 hours, and then repeatedly washed with deionized water until neutral, the bamboo charcoal was vacuum-dried in a vacuum oven at 100°C for 4 hours, and then the dried bamboo charcoal was ground and added to a 5.5mol / L ammonia solution, wherein the bamboo charcoal was 30% of the solution mass, shake at a constant temperature in a 55°C constant temperature oscillator for 5.5 hours, then repeatedly wash with deionized water until neutral, and then dry the bamboo charcoal in a vacuum oven at 100°C for 3.5 hours in vacuum;

[0049] (2) Grind the bamboo charcoal material prepared in step (1) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com