Method for co-producing high-purity rice starch and rice protein

A technology of rice starch and rice protein, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of not considering protein recycling, large consumption of lye, long reaction time, etc., to reduce nutrition The destruction of the product, the improvement of product purity, and the effect of product yield increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

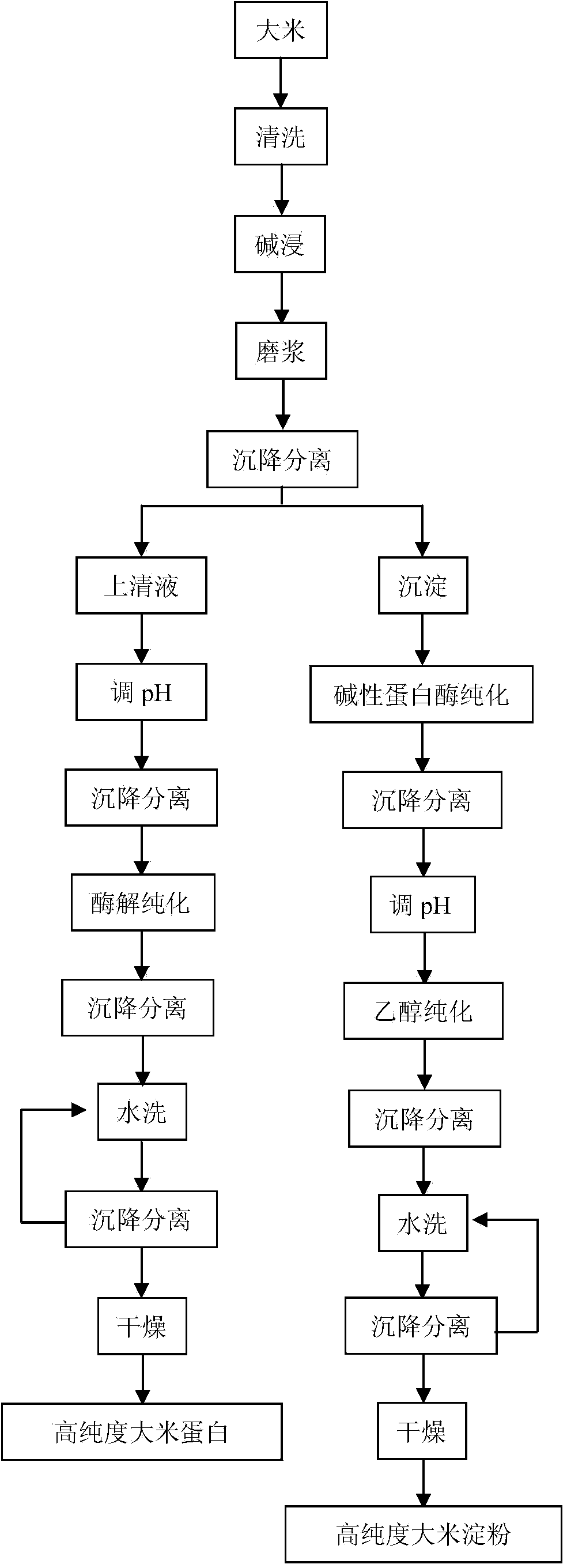

[0036] Embodiment 1 Basic production process example

[0037] Step 1: Take 250 kg of rice and wash the rice 3 times with 750 kg of tap water;

[0038] Step 2: Mix the washed rice with 0.4% NaOH solution at a solid-to-liquid ratio of 1:2, soak and stir at room temperature for 2 hours;

[0039] Step 3: Use a colloid mill to refine the soaked rice with a colloid mill, so that the rice pulp fineness reaches 100 mesh, separate it by conventional hydrocyclone separation, and store the supernatant and precipitate 1 from centrifugal filtration;

[0040] Step 4: Adjust the pH of the supernatant obtained in the previous step to 4.8 with hydrochloric acid, separate it with discs, and centrifuge the heavy phase (a conventional method) to obtain precipitate 2, add 625 kg of tap water, and add 1 kg of commercial starch at 55 ° C Enzyme (α-Amylase, Aladdin, BR, 5000U / g) was hydrolyzed for 25 minutes, separated with a hydrocyclone (conventional equipment), and the heavy phase was centrifuged...

Embodiment 2 comparative ( test Embodiment 1)

[0045] This embodiment adopts the basic method in Example 1 to produce rice starch and rice protein, but the pH adjusted by hydrochloric acid and the number of washings in Step 4 and Step 5 of Example 1 are changed respectively, and the yield and purity of the obtained rice protein are as shown in Table 1. shown. Among them, rice protein yield (%) calculation formula = protein product quality × (1 - protein product moisture content) / (rice raw material × rice raw protein crude protein content); rice protein purity (%) calculation formula = protein quality in the product × 100 / total product quality. It can be seen from Table 1 that the purity of rice protein under each condition can reach more than 85% (dry basis). The moisture content of rice protein is less than 14%. Considering comprehensively, the effect of pH 5 and washing 5 times is the best.

[0046] Table 1 Comparison of the effects of extracting rice protein under different conditions

[0047] serial numb...

Embodiment 3

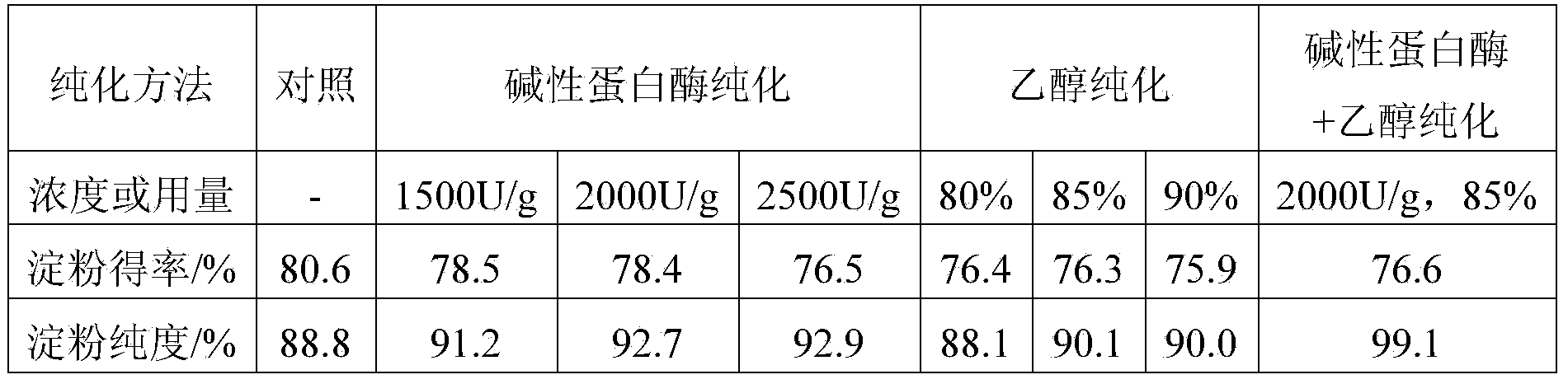

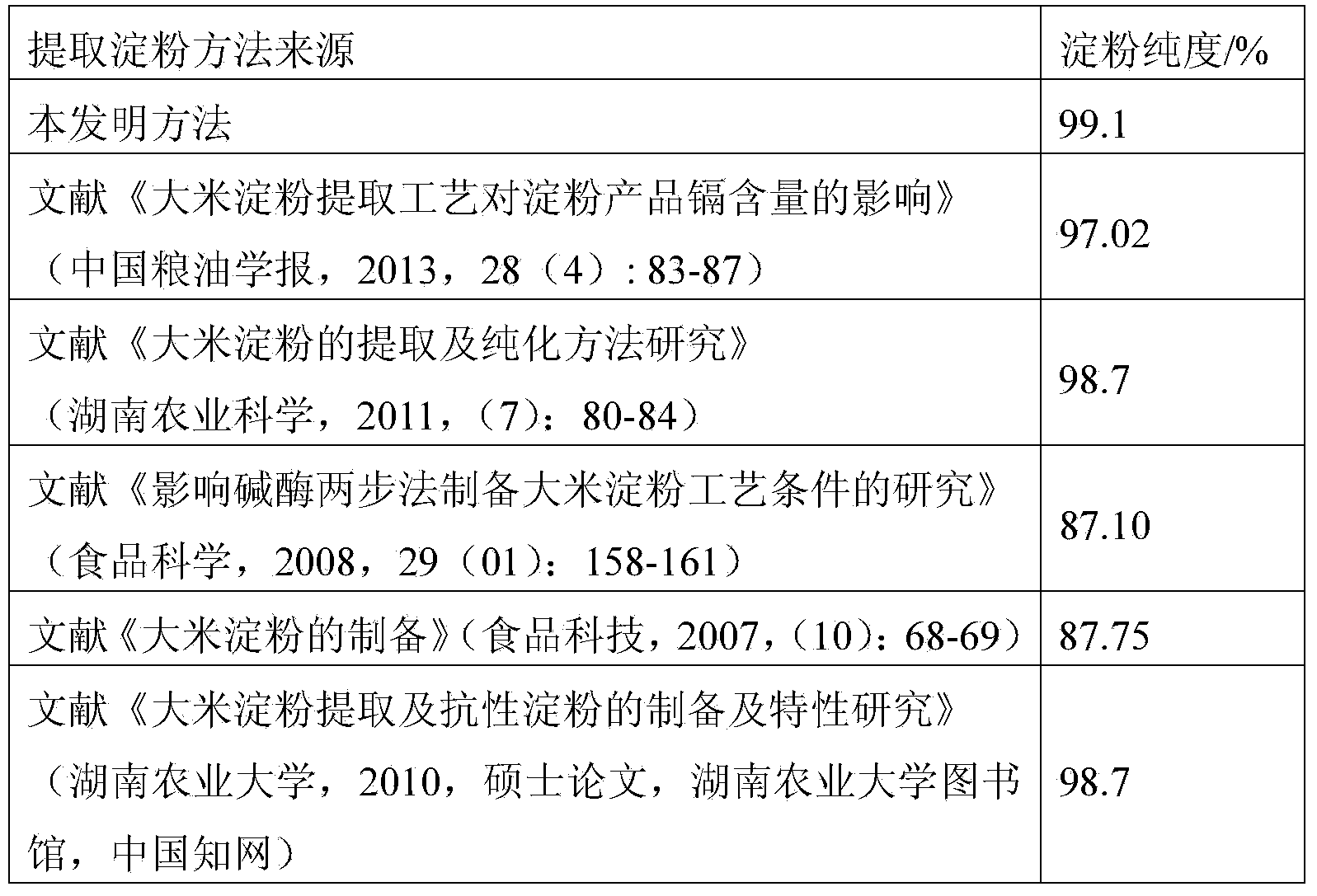

[0048] Embodiment 3 Comparison of rice starch purification methods (test example 2)

[0049] The present embodiment adopts the method in embodiment 1 to produce rice starch and rice protein, just change the purification method of rice starch in step 6 of embodiment 1, the yield and purity of rice starch are as shown in table 2. Among them, rice starch yield (%) calculation formula = starch product quality × (1-starch product moisture content) / (rice raw material × rice raw material starch content); rice starch purity (%) calculation formula = product starch quality × 100 / total product quality. As can be seen from Table 2, the two-step purification method of alkaline protease and ethanol can greatly improve the purity of rice starch. It is measured that the protein content of the rice starch prepared by the method is lower than 0.5% (dry basis), and the water content is lower than 14%. Among them, the starch purity obtained by adding alkaline protease 2000U / g and ethanol co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com