Visible-light response self-cleaning coating and preparation method thereof

A manufacturing method and self-cleaning technology, applied in the direction of coating, etc., can solve the problems of poor light transmission performance of glass, complex coating process, and influence on glass light transmission performance, and achieve good promotion value, low production cost, and easy construction convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The manufacture method of the visible light responsive self-cleaning coating of the present invention comprises the following steps:

[0026] 1. Preparation of titanium dioxide sol doped with metal ions and added with dispersant

[0027] Add tetrabutyl titanate to the hydrochloric acid solution with pH=3-5, stir at 30-60°C for 24 hours to carry out hydrolysis reaction, then add dispersant and metal salt, stir and mature at 70-90°C for 24 hours, A titanium dioxide sol doped with metal ions and added with a dispersant is prepared for use.

[0028] The mass ratio of hydrochloric acid solution, tetrabutyl titanate, dispersant and metal salt is 1-3:1:0.0012-0.0024:0.0024-0.0048.

[0029] The dispersant is any one of 200, 500, 1000, 2000 PEG or a mixture of two or more.

[0030] The metal salt is any one or a mixture of tungsten hexafluoride and vanadium tetrachloride.

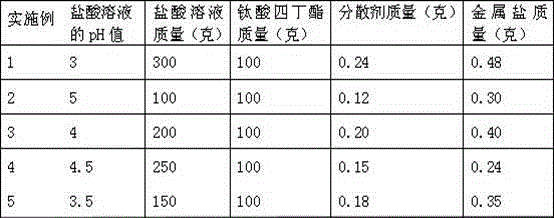

[0031] The specific implementation is shown in the table below:

[0032]

[0033] 2. Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com