Production method of high-purity polyvinyl alcohol

A production method and technology of polyvinyl alcohol, applied in the production field of high-purity polyvinyl alcohol, can solve the problems of increased use cost, solvent residue, raw material loss, etc., and achieve the effects of easy implementation, small material loss, and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

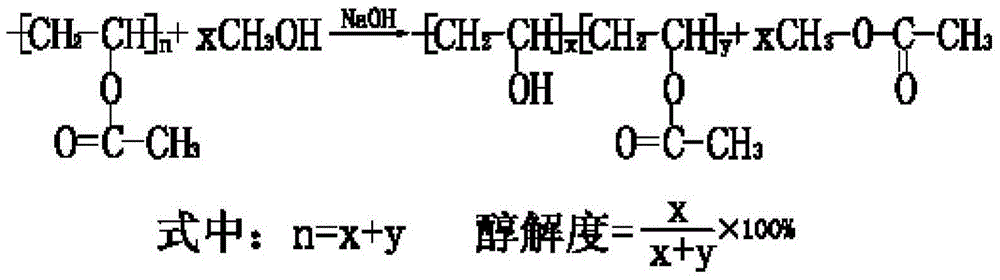

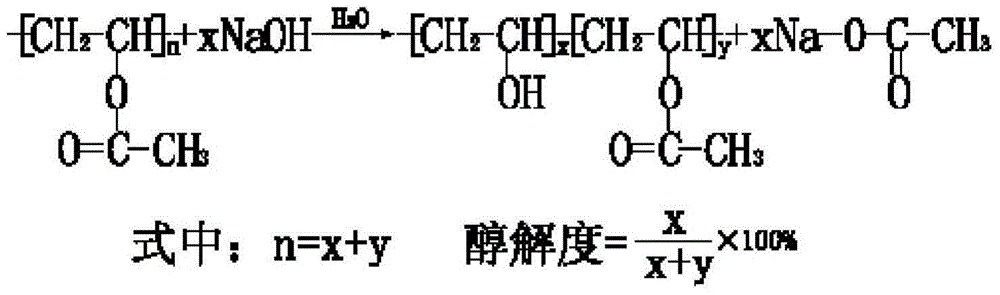

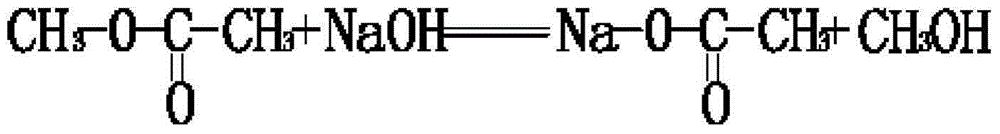

Method used

Image

Examples

Embodiment 1

[0029] Prepare low alcoholysis degree polyvinyl alcohol semi-finished products 17-88 from the production line (polymerization degree 1700±50, alcoholysis degree 88±2%), add it to the secondary alcoholysis kettle, and the mass ratio of input amount to alkali aqueous solution is 1:5 , the concentration of alkali aqueous solution is 25g / L, the temperature is 10°C, after reacting for 0.5 hours, add a small amount of acetic acid to neutralize. After overflow washing with desalinated water for 1 hour, it is sent to a centrifuge for separation, and the solid phase enters a vacuum dryer at a temperature of 0.05MPa-0.02MPa and 60-120°C for 1-2 hours. The finished product of polyvinyl alcohol was obtained and tested: the degree of alcoholysis was 99.7%, the content of sodium acetate was 0.25%, and the volatile matter was 0.39%.

[0030] Table 1 Example 1 data comparison

[0031] Test items

Embodiment 2

[0033] Prepare low alcoholysis degree polyvinyl alcohol semi-finished products 17-88 from the production line (polymerization degree 1700±50, alcoholysis degree 88±2%), add it to the secondary alcoholysis kettle, and the mass ratio of input amount to alkali aqueous solution is 1:5 , the concentration of the alkali aqueous solution is 12g / L, the temperature is 10°C, after reacting for 0.5 hours, add a small amount of acetic acid for neutralization. After overflow washing with desalinated water for 1 hour, it is sent to a centrifuge for separation, and the solid phase enters a vacuum dryer at a temperature of 0.05MPa-0.02MPa and 60-120°C for 1-2 hours. The finished product of polyvinyl alcohol was obtained and tested: the degree of alcoholysis was 92.9%, the content of sodium acetate was 0.26%, and the volatile matter was 0.42%.

[0034] Table 2 Example 2 data comparison

[0035] Test items

Embodiment 3

[0037] Prepare low alcoholysis degree polyvinyl alcohol semi-finished product 17-92 from the production line (polymerization degree 1700±50, alcoholysis degree 92±2%), put it into the secondary alcoholysis kettle, and the mass ratio of the input amount to the alkali aqueous solution is 1:5 , the concentration of the alkali aqueous solution is 15g / L, the temperature is 10°C, after reacting for 0.5 hours, add a small amount of acetic acid for neutralization. After overflow washing with desalinated water for 1 hour, it is sent to a centrifuge for separation, and the solid phase enters a vacuum dryer at a temperature of 0.05MPa-0.02MPa and 60-120°C for 1-2 hours. The finished product of polyvinyl alcohol was obtained and tested: the degree of alcoholysis was 99.5%, the content of sodium acetate was 0.31%, and the volatile matter was 0.33%.

[0038] Table 3 Example 3 data comparison

[0039] Test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com