Tension mechanism of winding machine

A technology of tension mechanism and winding machine, which is applied in the field of tension mechanism of winding machine, can solve problems such as unstable quality of battery cells, difficult to control tension, S-shaped defects of cells, etc., achieve compact structure, reduce labor costs, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

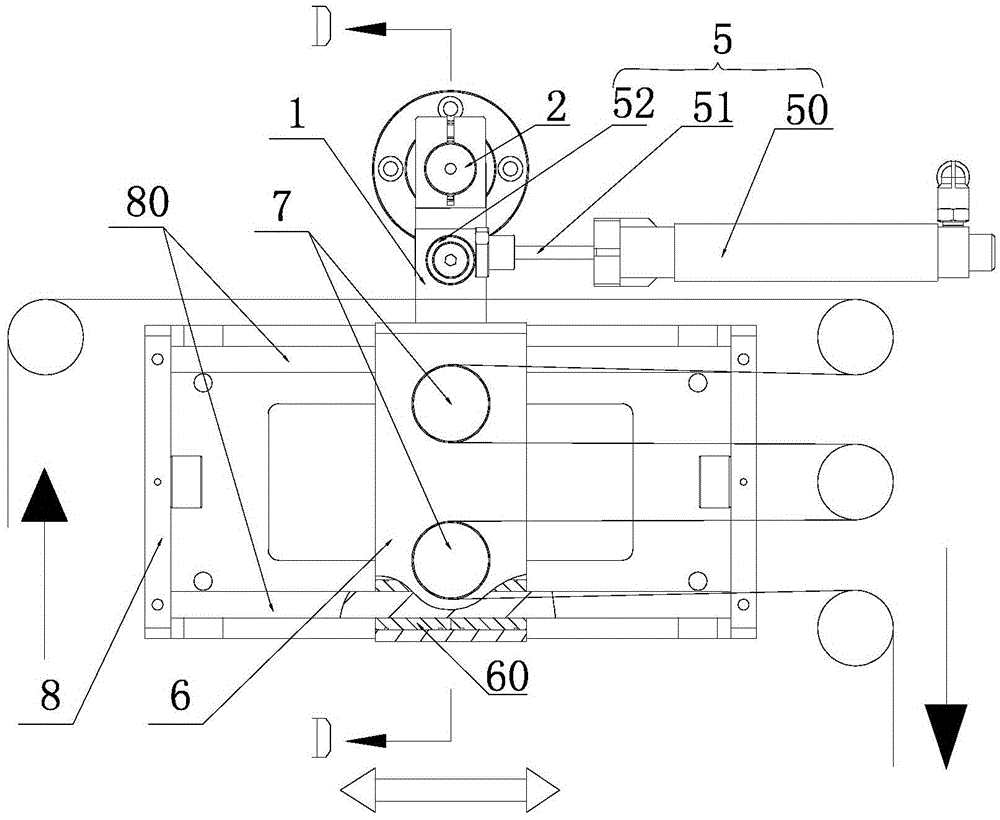

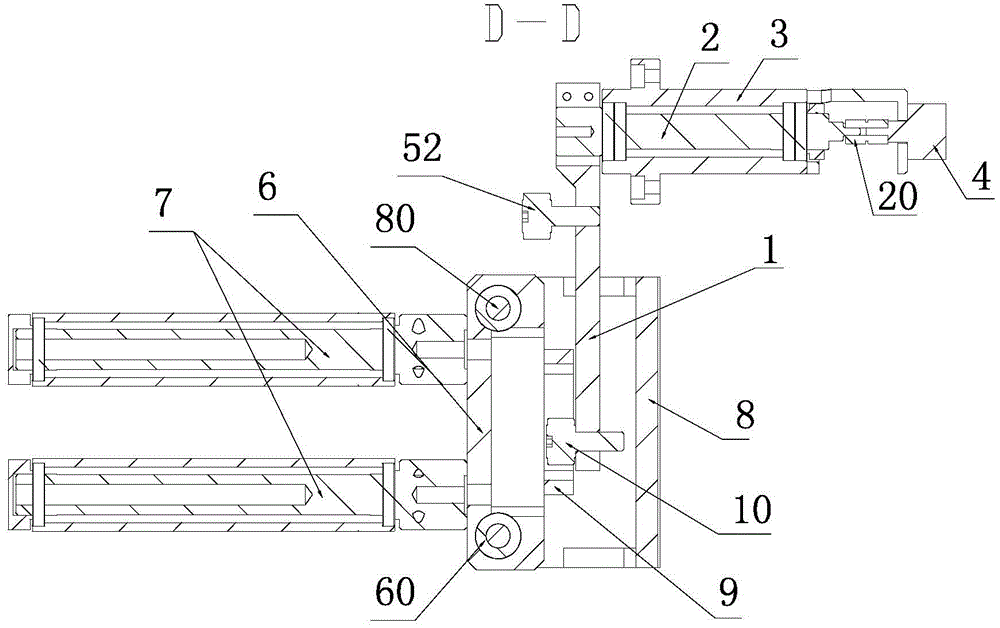

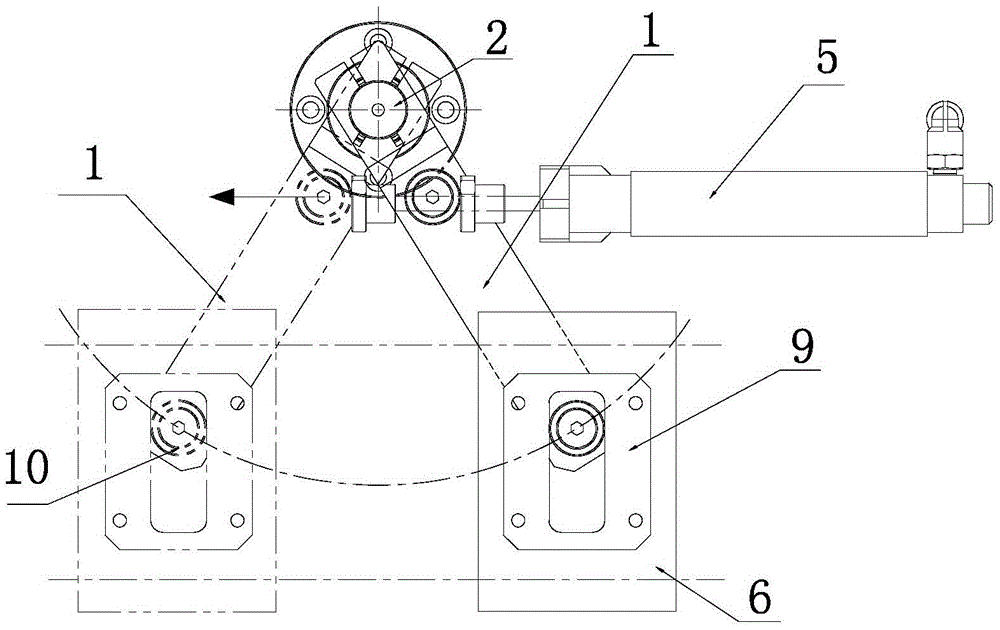

[0016] The tension mechanism of the winding machine, such as Figure 1 to Figure 3 As shown, it is applied to the winding of lithium-ion battery cores. It includes a swing arm 1, a rotating shaft 2, a bearing seat 3, a potentiometer 4 and a constant voltage device 5. The rotating shaft 2 is installed on the body through the bearing seat 3. The swing arm 1 The upper end is fixed on the front end of the rotating shaft 2, and the constant tension device 5 pushes the swing arm 1 at the front end of the rotating shaft 2 to deflect at a certain angle. It is connected with the rotating shaft 2 through a coupling 20; a sliding seat 6 is movably connected to the lower end of the swing arm 1, and two tension rollers 7 arranged parallel to the axis of the rotating shaft 2 are installed on the sliding seat 6. The upper and lower sides of the seat 6 are arranged side by side; the rear side of the sliding seat 6 is provided with a sliding seat frame 8, and the sliding seat frame 8 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com