Roller body for roller bearing

A technology of rolling bearings and rolling elements, applied in the field of rolling elements, can solve the problems of material and cost consumption, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

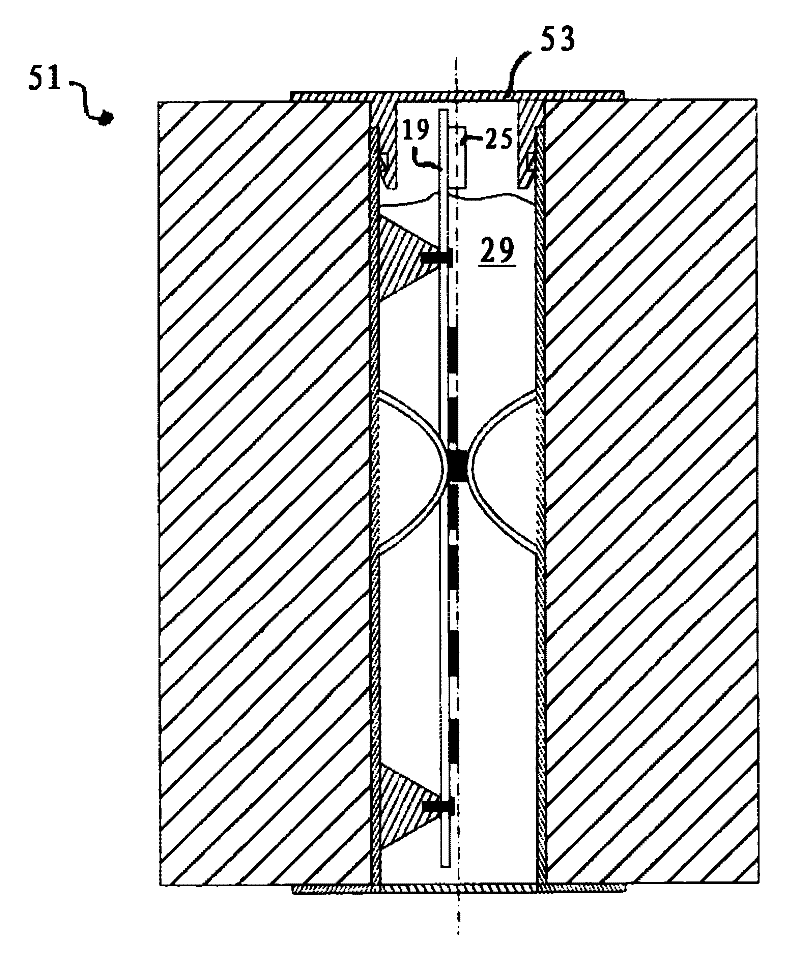

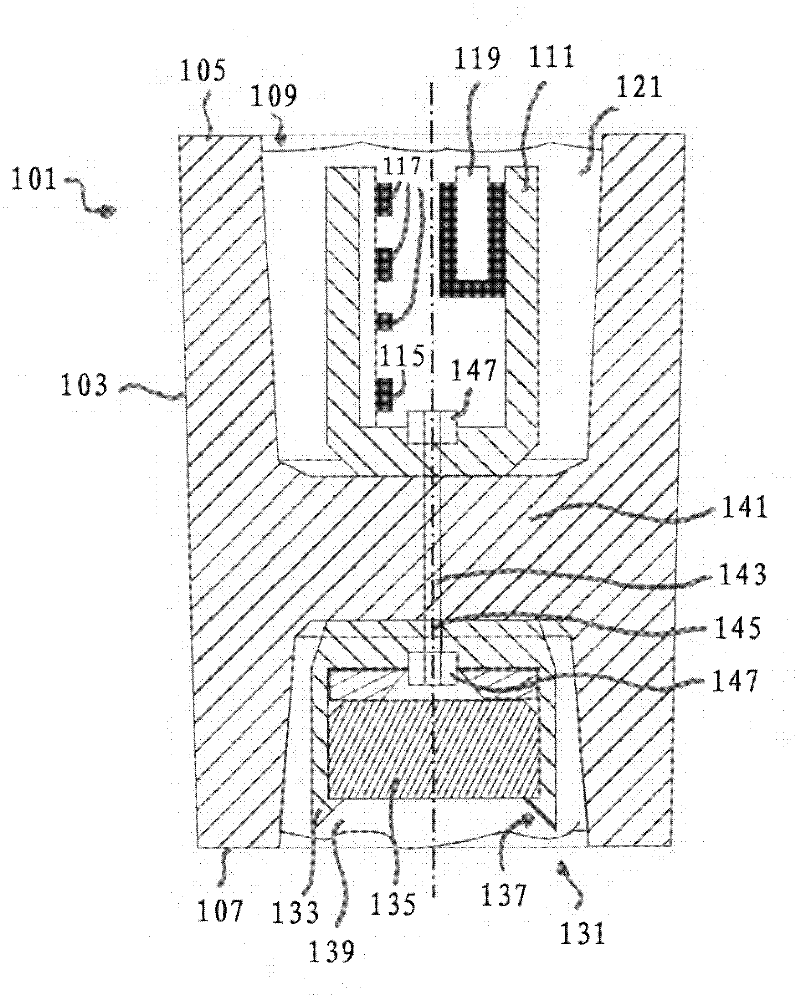

[0029] The embodiments described below relate by way of example to cylindrical or tapered rollers. Correspondingly, however, other types of rollers, such as spherical rollers, cylindrical and tapered rollers, can also be configured accordingly. exist figure 1 In , a cylindrical roller 1 is shown as an embodiment of the present invention. The cylindrical roller 1 has a radially surrounding running surface 3 , by means of which the cylindrical roller 1 can make rolling contact with an inner ring or an outer ring (not shown here) of the rolling bearing. Furthermore, the cylindrical roller 1 has two end sides 5 and 7 that essentially have a round basic shape. A bore 9 arranged centrally in the cylindrical roller 1 extends between the end sides 5 and 7 . A support 11 is arranged in the bore 9 , which likewise has a hollow cylindrical basic shape. The outer diameter of the bracket 11 is adapted to the inner diameter of the hole 9 .

[0030] In order to securely fix the carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com