Wire harness welding machine

A welding machine and wire harness technology, applied in welding equipment, connections, circuit/collector parts, etc., can solve the problems of uneven tinning, easy breakage and damage, and easy rotation of tin wires, so as to reduce the amount of tin and improve the Accuracy, not easy to break and damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

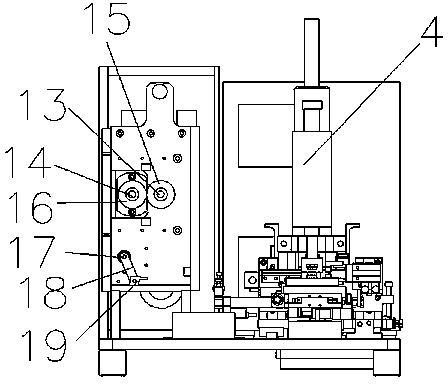

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as Figure 1-4 As shown, a wire harness welding machine includes a base 1, a discharge rack 2, a motor 3, a welding machine body 4, jaws 5, a clamping cylinder 6, a carrier table 20, a moving frame 7 and a pushing cylinder 8, and on the base 1 is provided with a discharge rack 2, and the discharge rack 2 includes a front panel 10 and a rear panel 11, and a support shaft 9 for placing a tin wire reel is provided at the top position of the front panel 10 of the discharge 2 rack. Frame 2 rear panel 11 rear end is provided with motor 3, is provided with driving shaft 13 and driven shaft 14 between the front and rear panels of discharging rack 2, is provided with main gear 12 in the middle part of driving shaft 13, and is arranged in the middle part of driven shaft 14. There is a slave gear meshed with the main gear 12, the output shaft of the motor 3 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com