Three-dimensional (3D) metal printer

A printer and metal technology, applied in the field of 3D printers and CNC machining, can solve the problems that 3D printers cannot be used, all metal manufacturing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

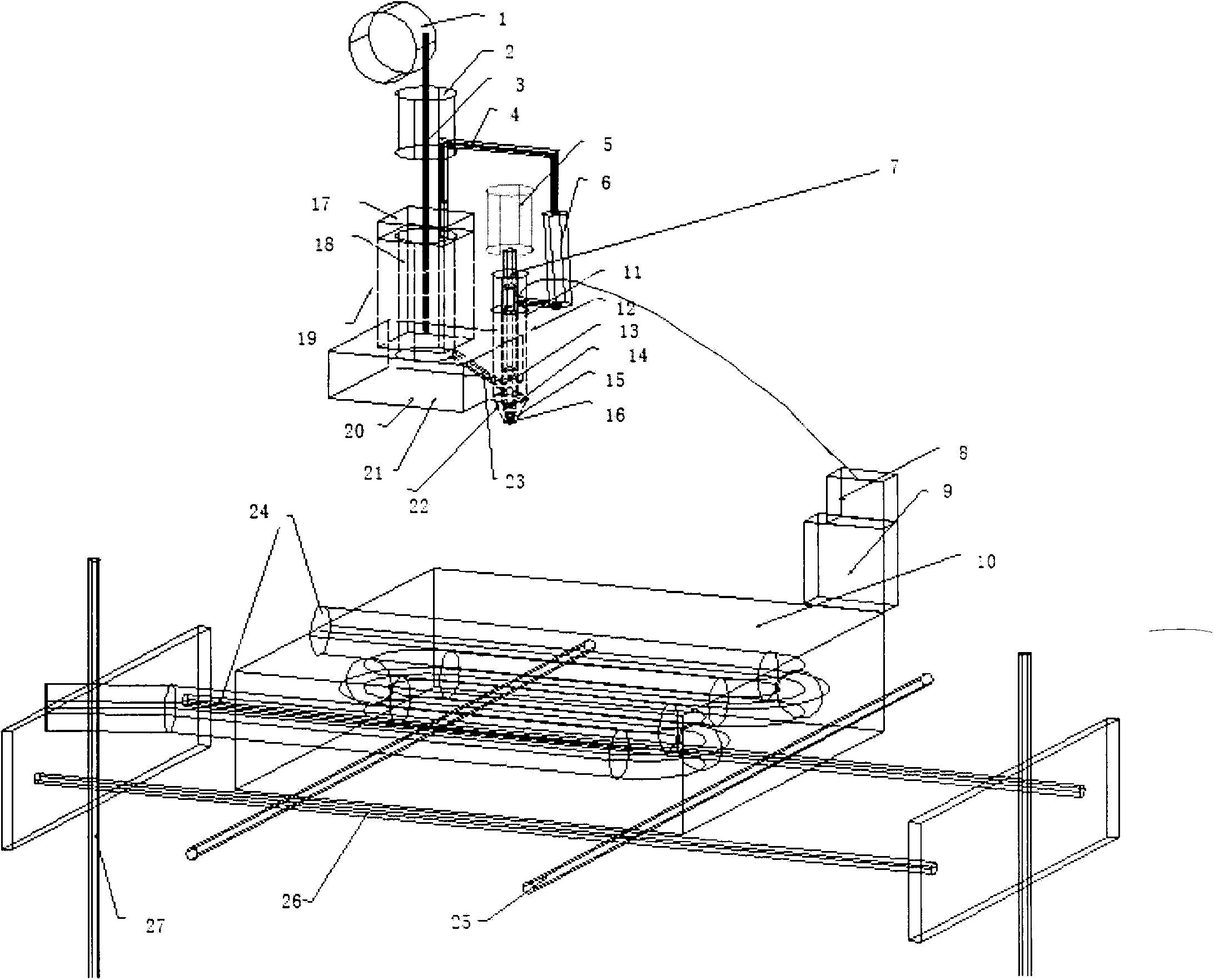

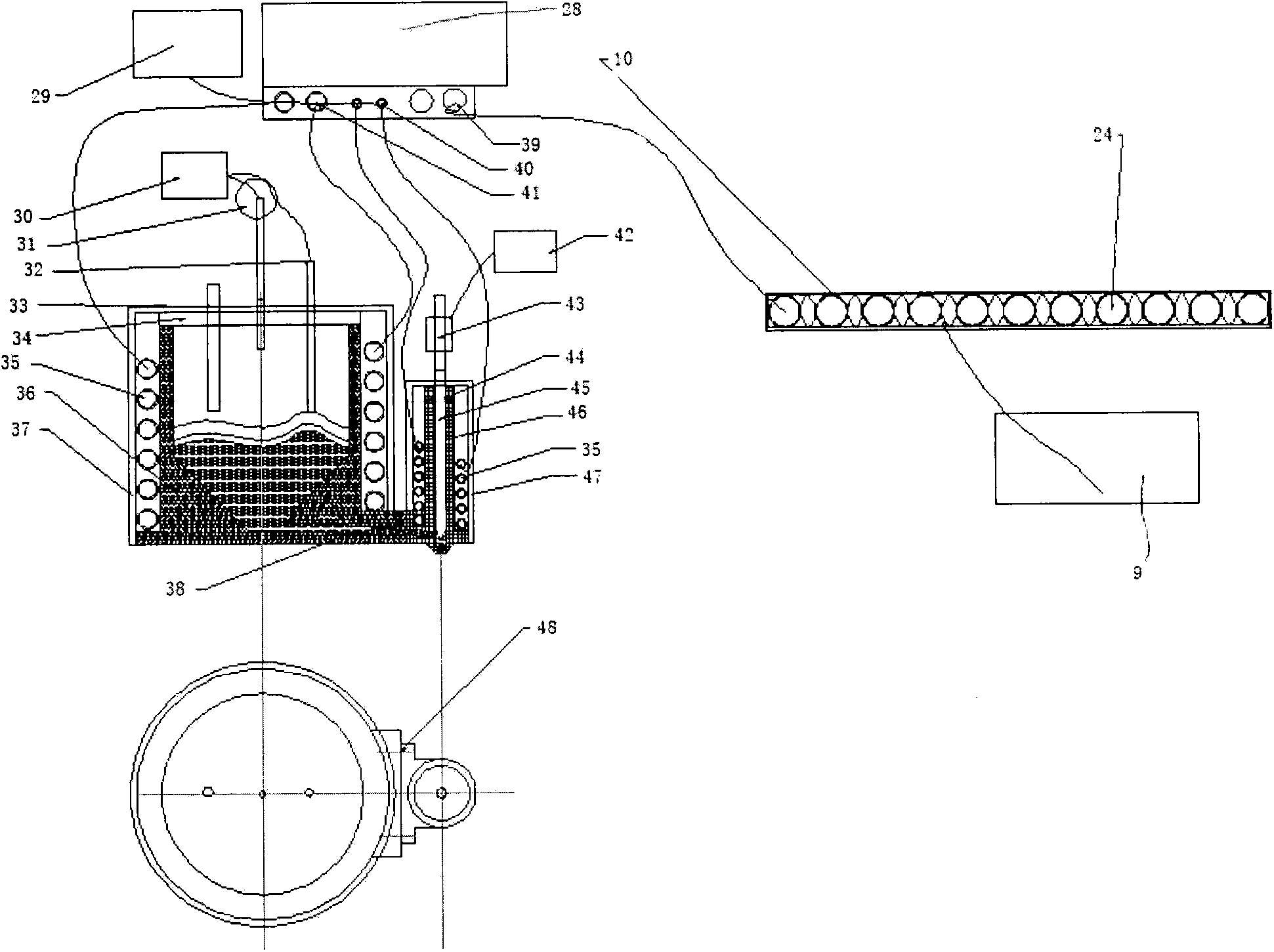

[0017] Example: such as figure 1 and figure 2 A 3D metal printer shown.

[0018] The print head integrating ceramic melting furnace and liquid metal injector is the key technology of this 3D printer:

[0019] The print head is made of high temperature resistant ceramic or graphite material, the outer layer is equipped with a water-cooled electric eddy current coil 19, the melting furnace is filled with inert gas to protect the liquid metal, and the injector is a reciprocating plunger pump. The water-cooled eddy current coil is fed with high-frequency current, and the heating power can be adjusted by the high-frequency controller according to the material type, model requirements, processing speed and other factors. The reciprocating frequency of the plunger pump plunger is adjusted according to the nonlinear function with the XYZ direction speed of the workbench, and the eddy current heating coil on the plunger pump is turned on or off according to factors such as shutdown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com