Die-casting double-bottom cooking utensil and manufacturing method thereof

A production method and technology of cooking utensils, which are applied in the field of machinery, can solve the problems of expansion and bulging of the double bottom, connection gaps at the bottom of the pot, and deformation of the double bottom, and achieve the effects of prolonging the service life, enhancing the firmness of the connection, and eliminating deformation stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

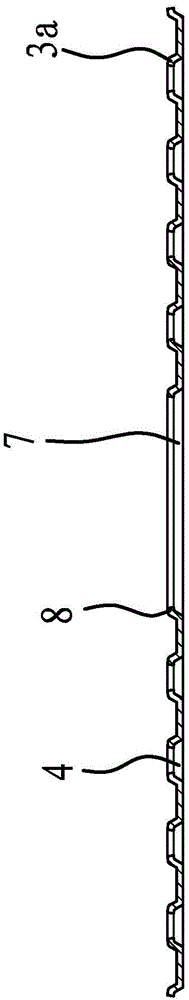

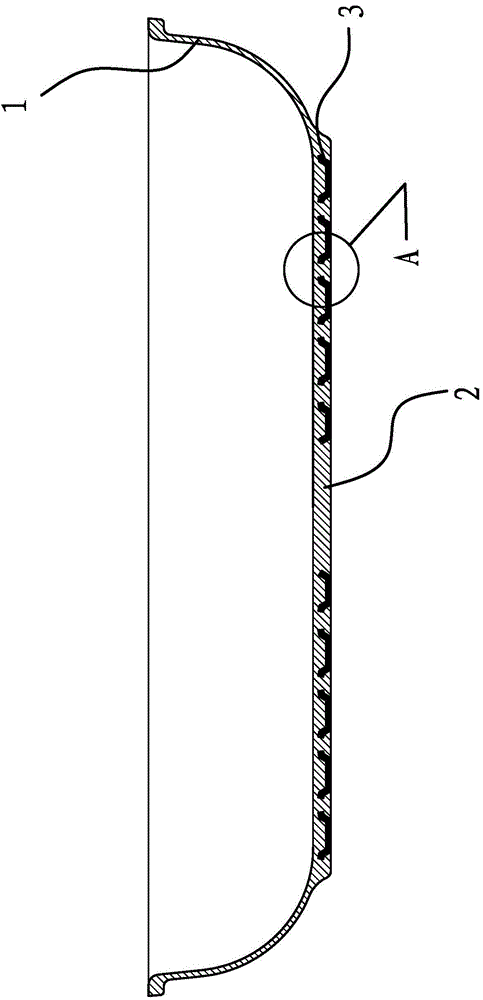

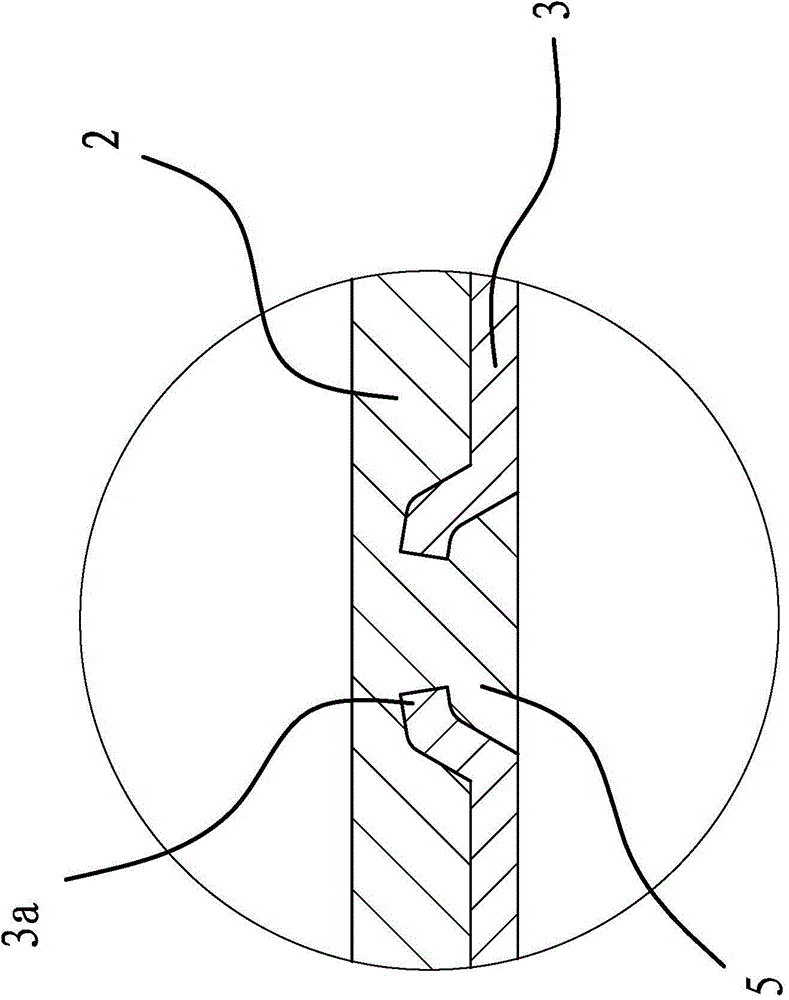

[0051] Such as figure 1 — Figure 5 As shown, a die-casting double-bottom cooker includes an open body 1 made of aluminum material. The body 1 has a chassis 2 for heating, and the chassis 2 has a metal sheet 3 of magnetically conductive material. The metal sheet 3 has a number of through connection holes 4, and the chassis 2 has a number of connection parts 5 embedded in the connection holes 4. The connection parts 5 match the connection holes 4 and the connection parts 5 correspond to the connection holes 4 one by one. It is flush with the metal sheet 3, and there is a clamping structure between the connecting hole 4 and the connecting part 5, which can make the two firmly connected. The clamping structure includes a pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com