Oven for grilling food

An oven and food technology, applied in the field of ovens for baking food, can solve the problems of heat dispersion, unhygienic, and inconsistent arrival of heat, etc., and achieve the effect of ensuring cleaning and easy cleaning operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

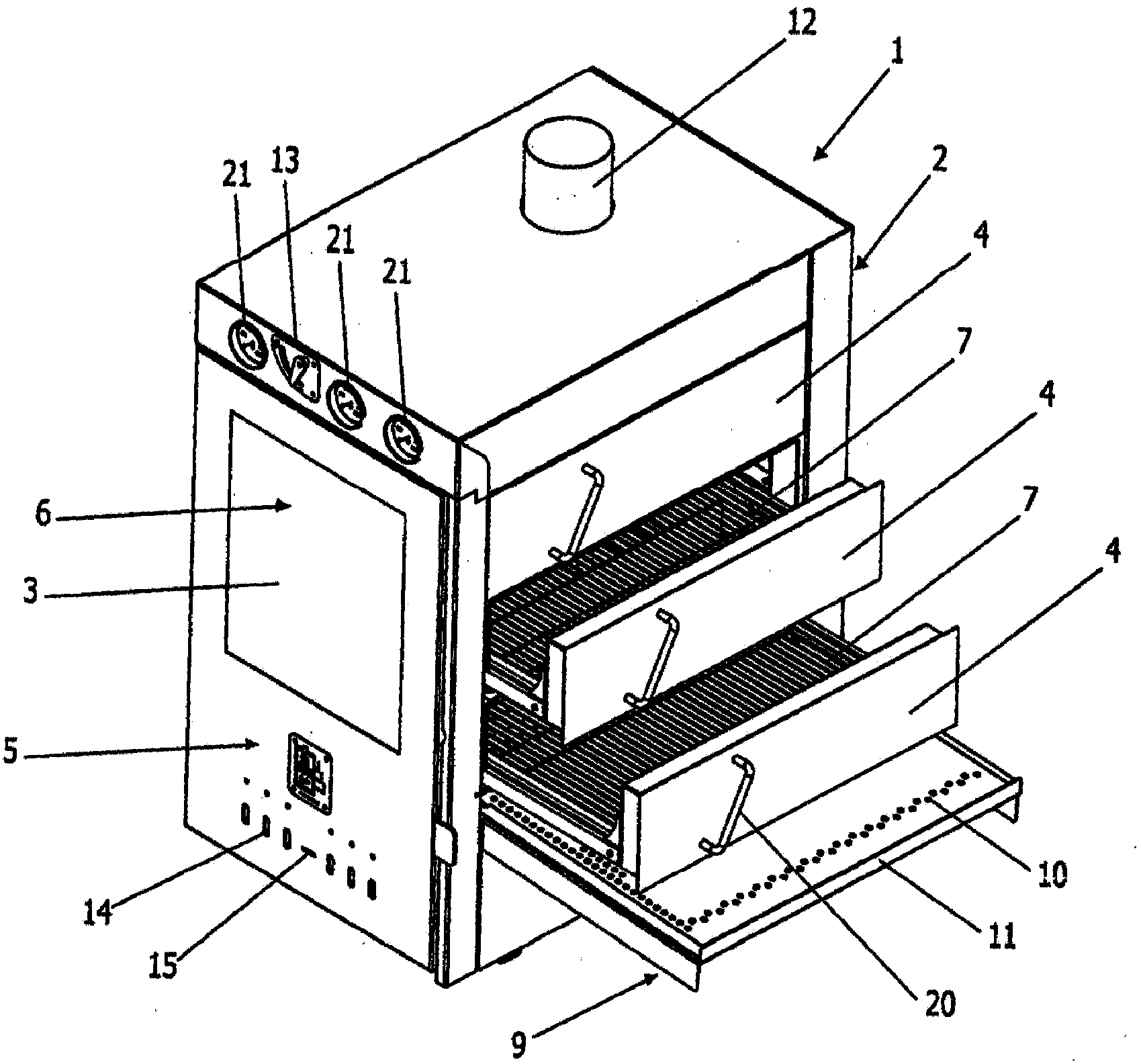

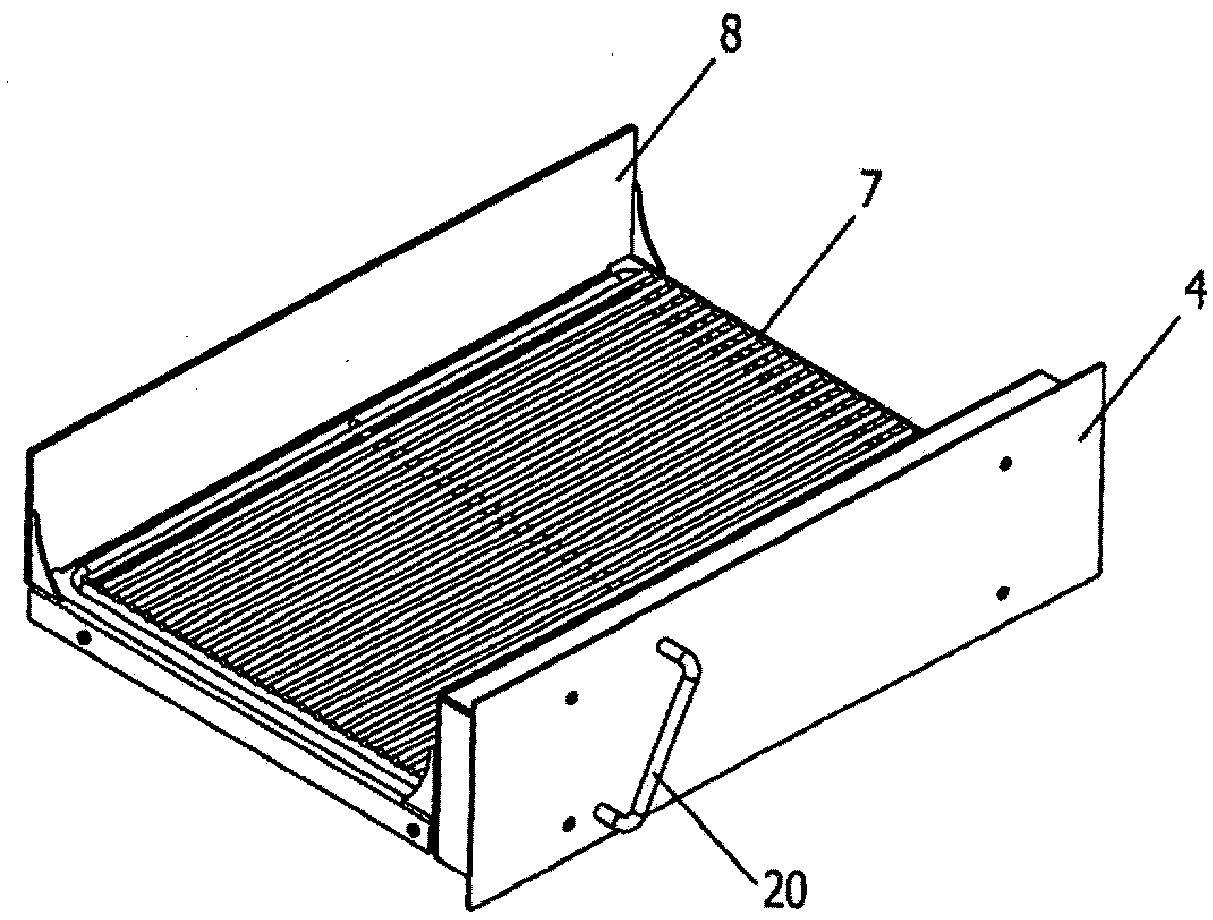

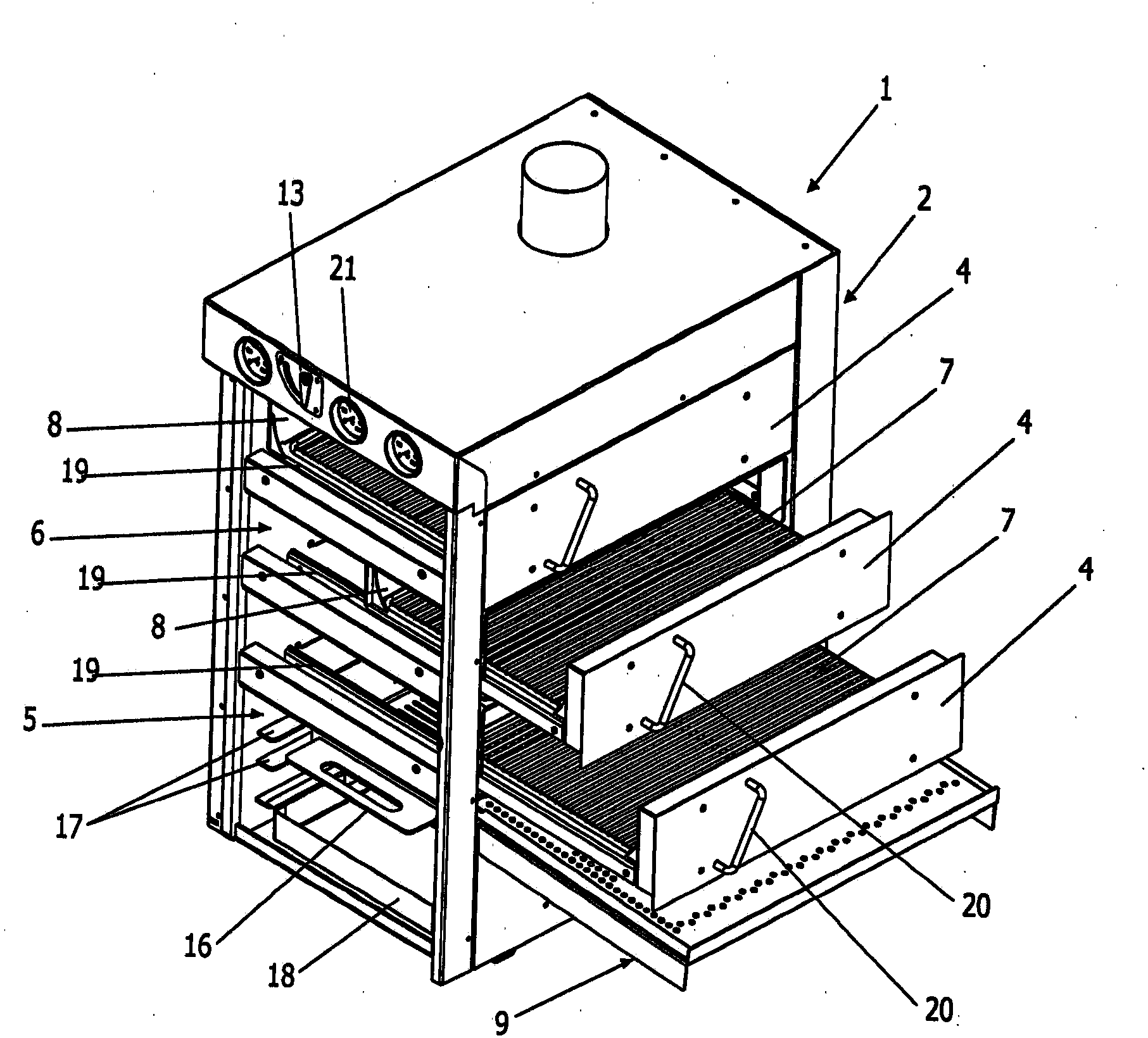

[0049] Referring to the drawings, there is shown an oven 1 for grilling food, in particular an oven powered by solid fuel such as wood or charcoal.

[0050] The oven comprises an enclosure 2 made of steel walls defining an interior space subdivided into a heat generating zone 5 and a cooking zone 6 .

[0051] At the front of said housing 2 there is a transparent glass part 3 .

[0052] Corresponding to the position of the transparent part 3, the housing 2 can be opened for cleaning operations and for preparing the oven for use.

[0053] Fuel to be combusted is placed in said heat generating zone 5 and food is arranged in said cooking zone 6 .

[0054] In particular, said heat generating zone 5 includes a grid 16 for supporting the solid fuel.

[0055] Said support grate 16 cooperates with suitable support means 17, guides or projections placed at different heights relative to said cooking zone 6 above.

[0056] Said heat generating zone 5 also comprises a tray 18 arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com