Composite type electric generator based on electromagnetism and friction principle

A composite generator technology, applied in the field of micro-energy, can solve the problems that devices with small internal resistance cannot supply energy efficiently, the output current of the friction nano-generator is small, and the matching load of the friction nano-generator is high. Effects of large-scale production, improved energy conversion efficiency, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

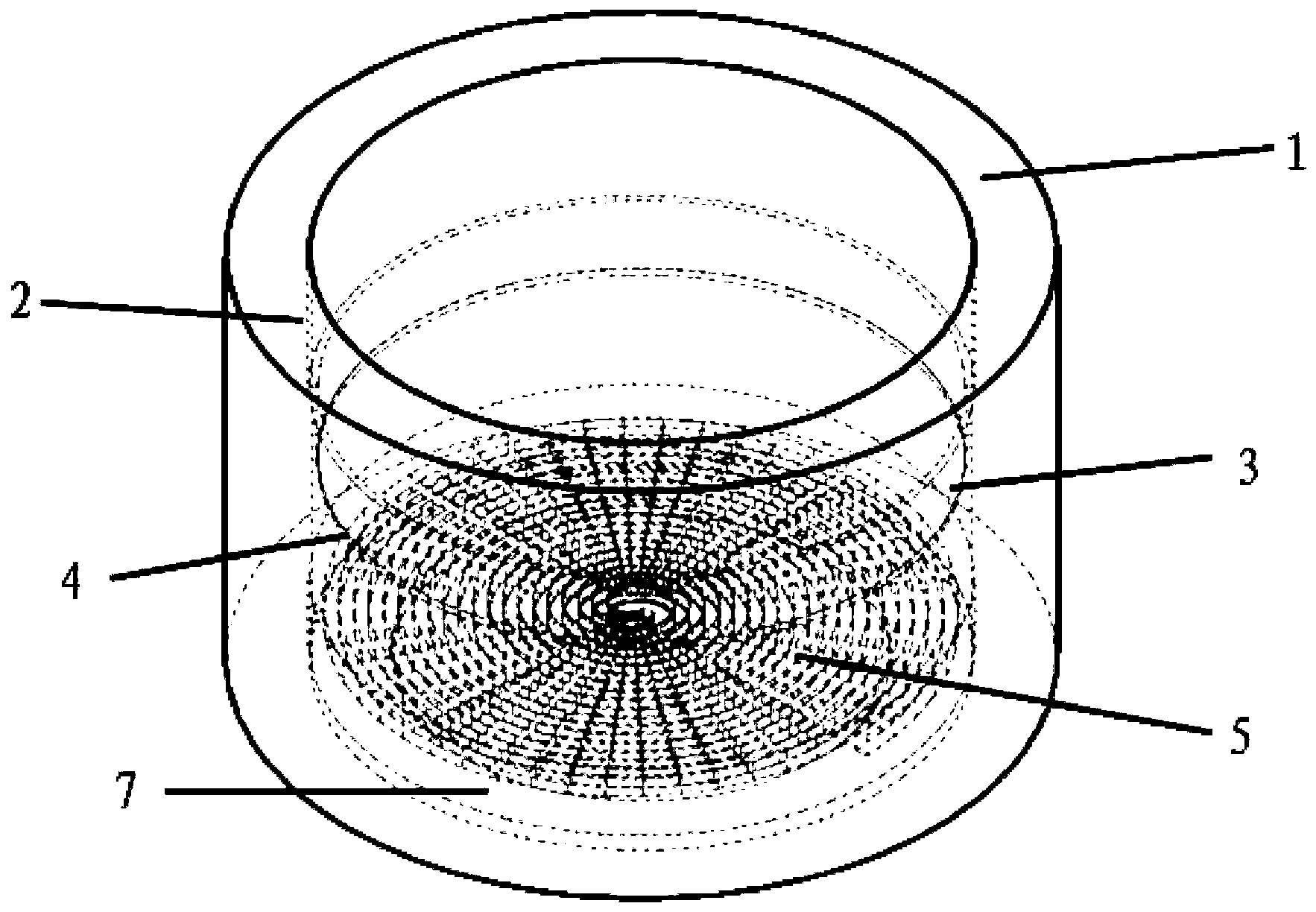

[0024] Example: such as Figures 1 to 6 As shown, it includes shell 1, top mass 2, top permanent magnet 3, friction layer 4, metal coil 5, film 6, bottom permanent magnet 7,

[0025] The shell 1 is made of polytetrafluoroethylene (PTFE), the inner diameter of the shell 1 is preferably 20 mm, the outer diameter is preferably 2 mm, and the height is preferably 25 mm;

[0026] The uppermost layer of the shell 1 is equipped with a top mass block 2, the top mass block 2 is made of metal iron, and the mass is preferably 30g;

[0027] The top permanent magnet 3 is installed under the top mass 2, which is made of neodymium-iron-boron (NdFeB) material;

[0028] A friction layer 4 of silicon rubber material is installed under the top permanent magnet 3;

[0029] A metal coil 5 is installed under the friction layer 4, the material of the metal coil 5 is metal copper, the width of the metal coil 5 is preferably 150 μm, the spacing is preferably 100 μm, and the height is preferably 30 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com