Coal powder drying device

A technology of drying device and pulverized coal, applied in the field of machinery, can solve the problems of unsuitability for continuous online drying, slow heat conduction, long drying time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In view of this, the core of the present invention is to provide a coal powder drying device to achieve the purpose of drying coal samples on-line.

[0035] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

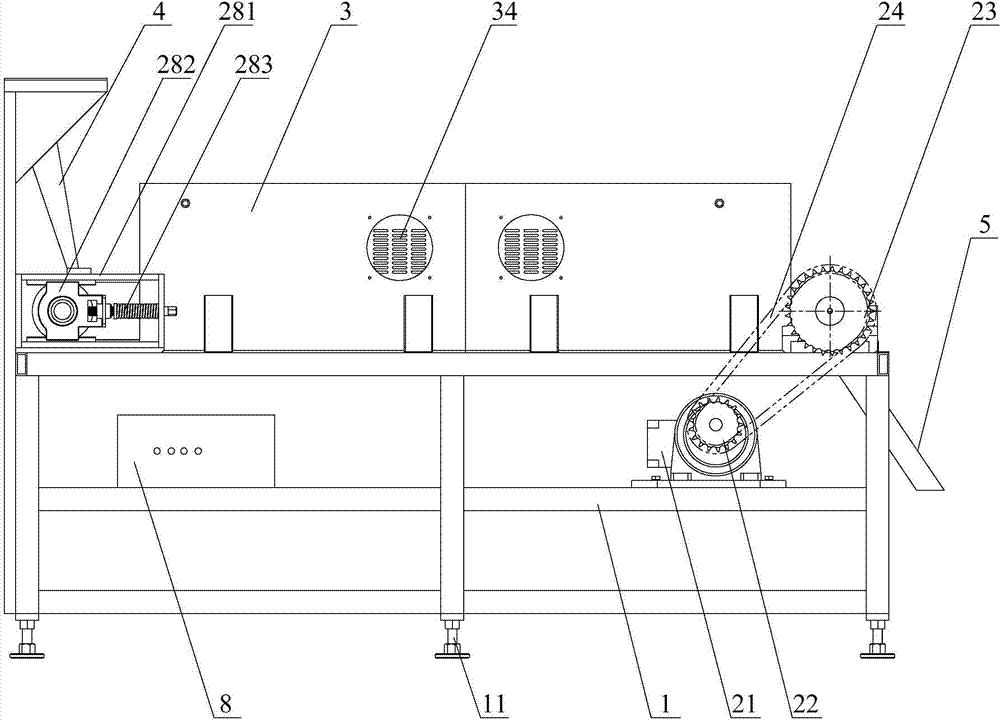

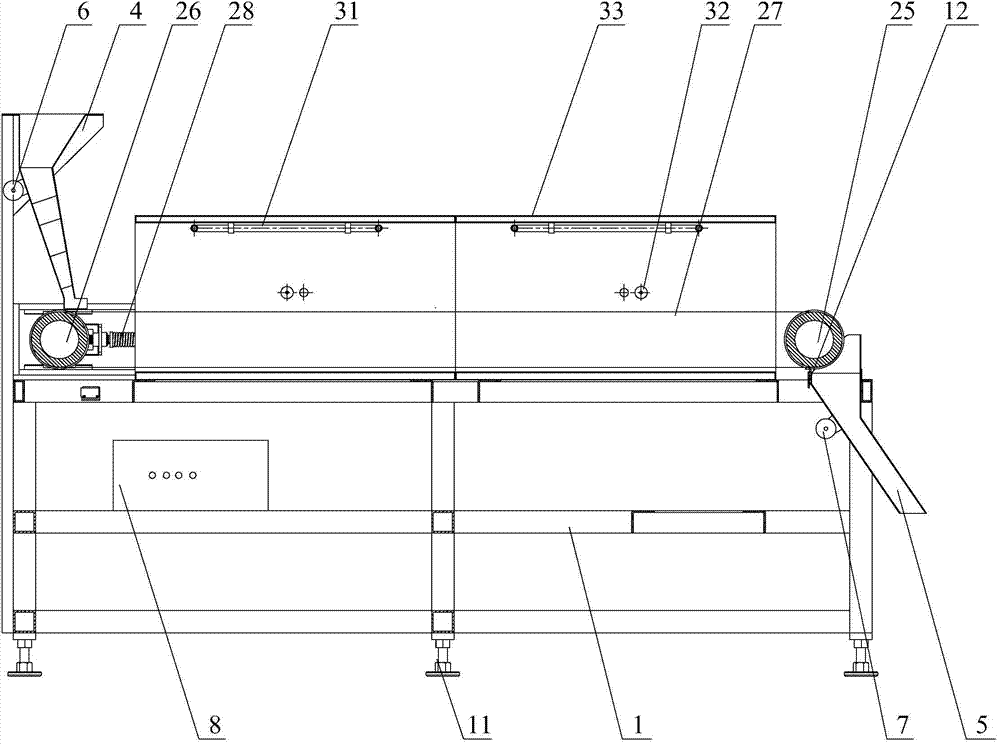

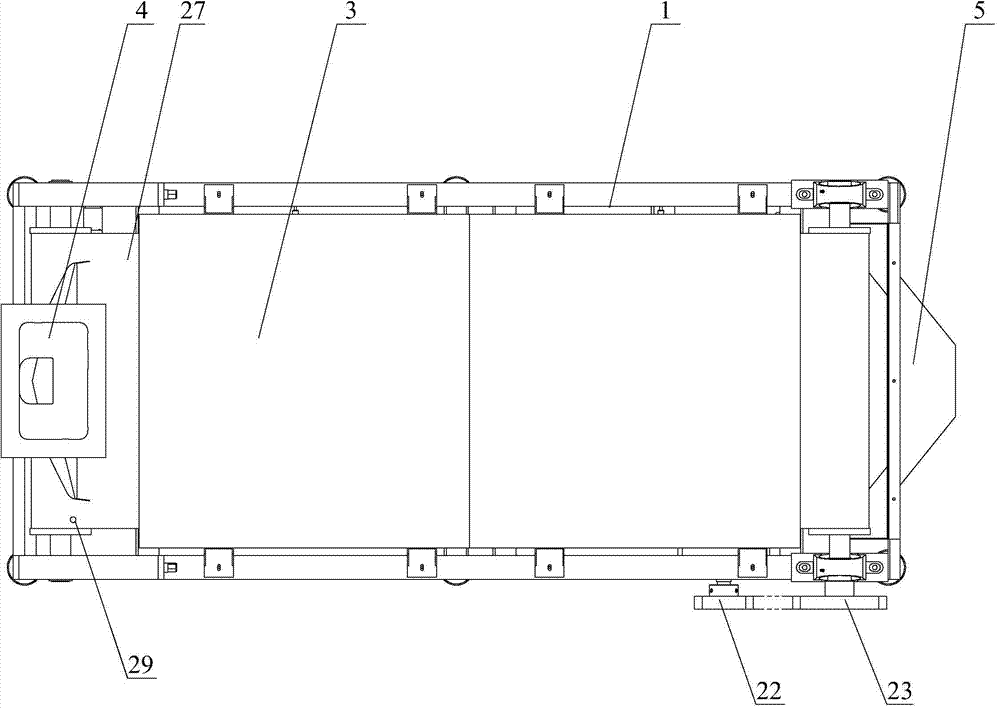

[0036] Such as Figure 1 to Figure 3 As shown, the pulverized coal drying device includes: a frame 1; a transmission mechanism arranged horizontally on the frame 1; a drying box 3 arranged on the frame 1 and above the transmission mechanism, and the drying box 3 is provided with infrared heating pipe 31; a distributor at the feed end of the conveying mechanism; and a feeder 5 at the discharge end of the conveying mechanism.

[0037] When the pulver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com