Two-way control valve suitable for height adjustment system of short wall shearer

A short-wall shearer and two-way control technology, which is applied in the direction of mechanical equipment, servo motor components, fluid pressure actuators, etc., can solve problems that affect work reliability, high opening pressure of balance valves, high working pressure of pumps, etc., to achieve Effects of improving work reliability and reducing work stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

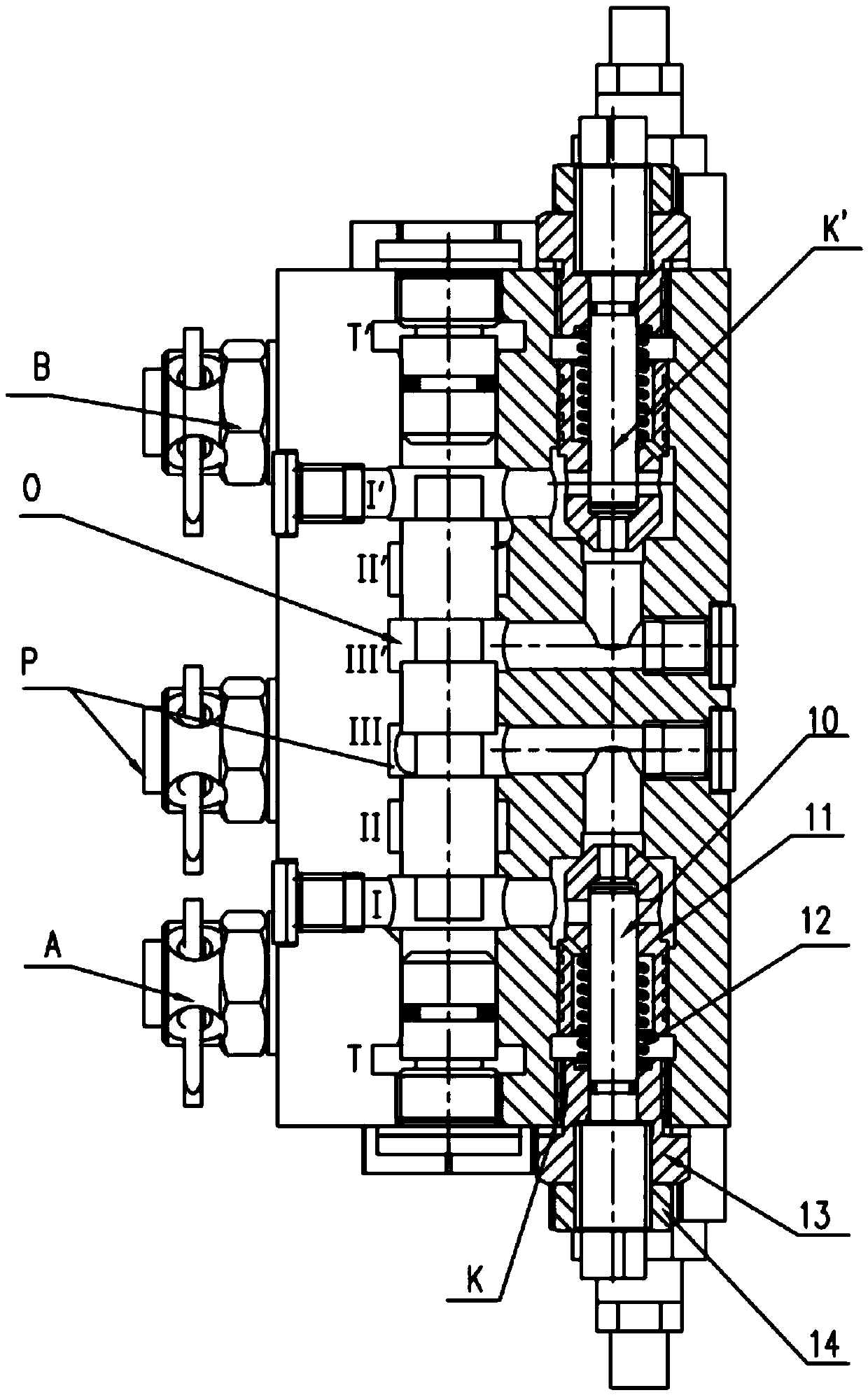

[0042] The invention discloses a two-way control valve suitable for a height adjustment system of a short-wall shearer, which highly integrates four functional structures of a hydraulic lock, a one-way throttle valve, a safety valve and a reversing valve on one valve block.

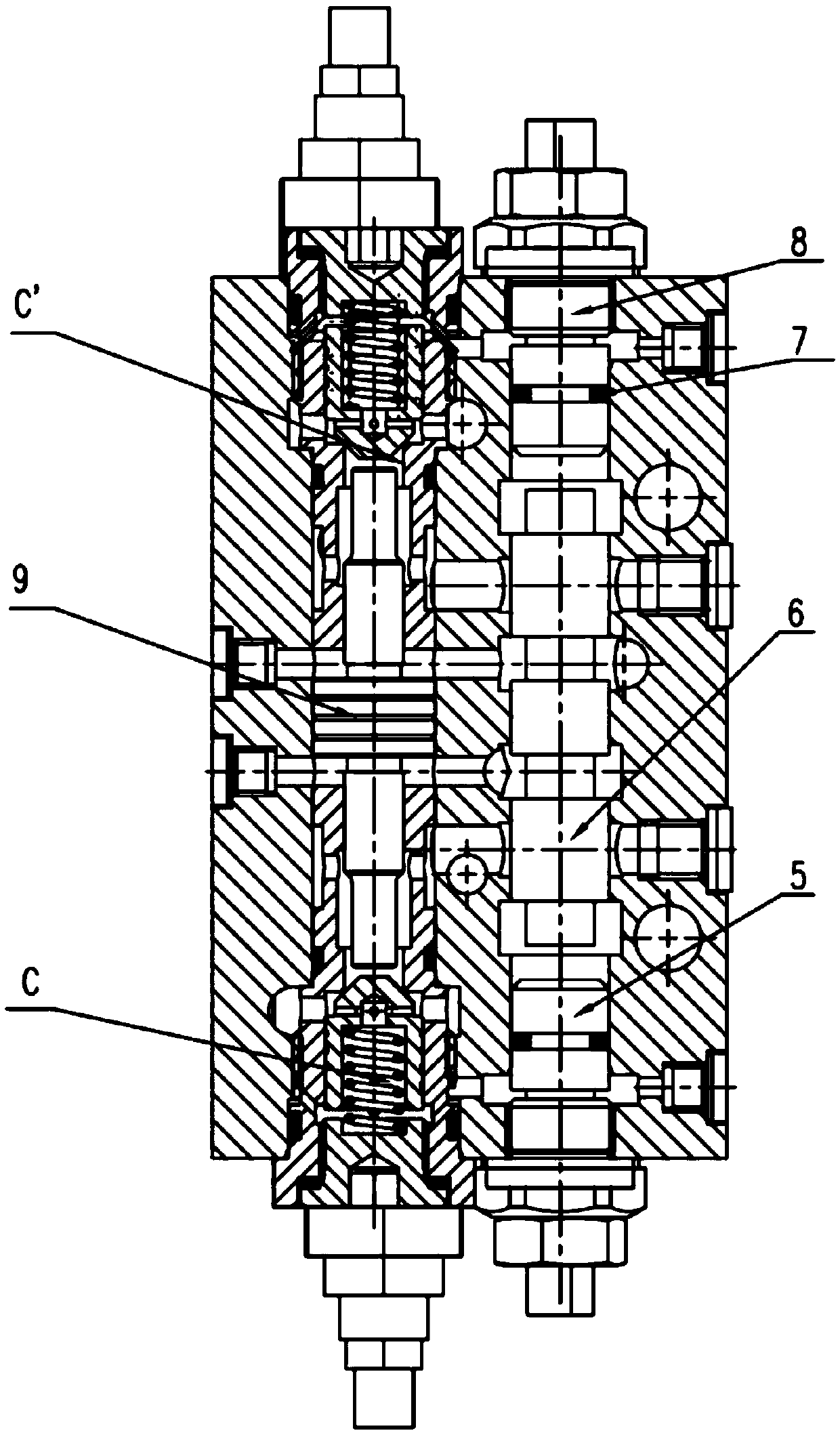

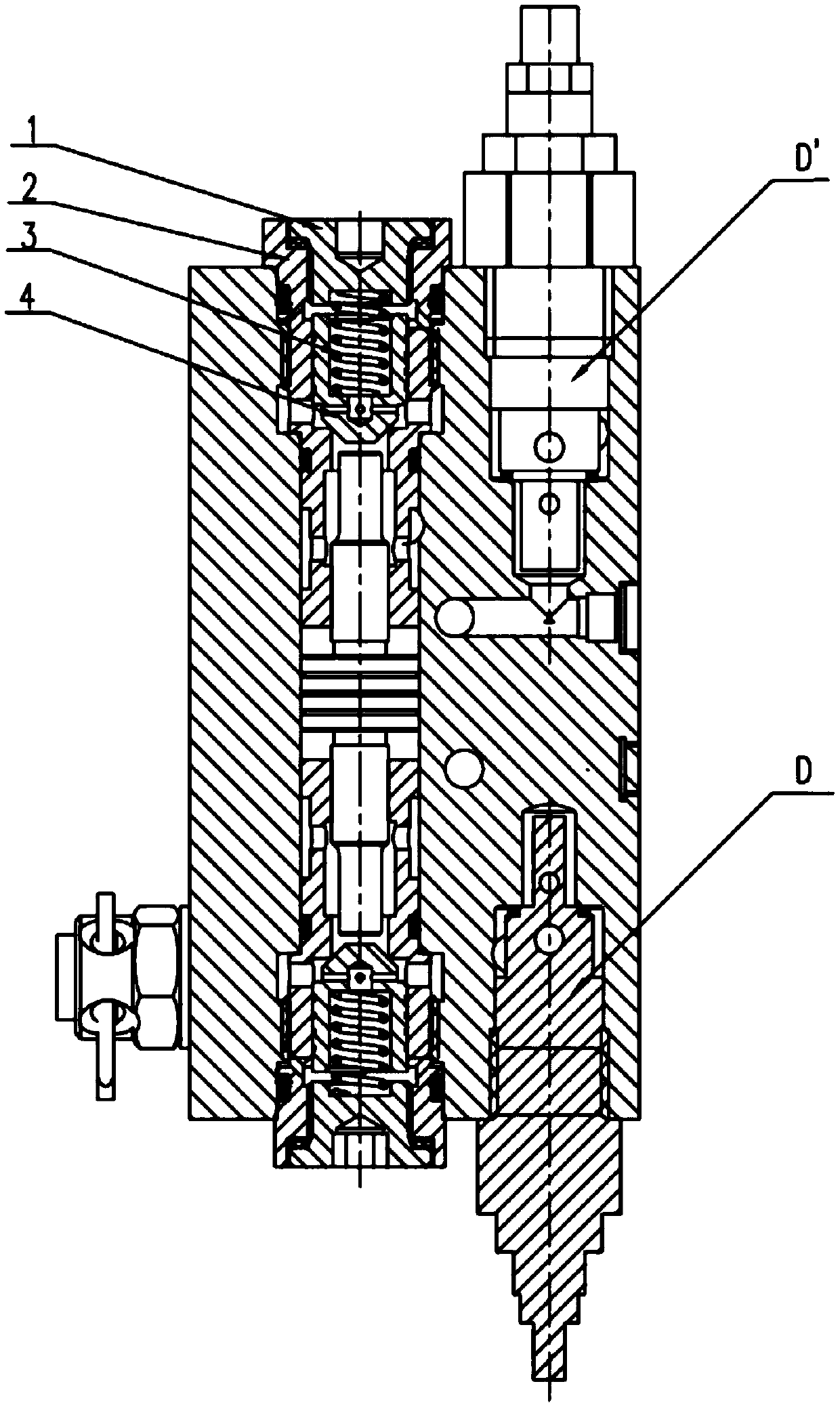

[0043] see figure 1 , the hydraulic lock consists of a piston 9 and two hydraulic control check valves C, C', such as image 3 As shown, the hydraulic control check valve includes valve seat 2, return spring 3, valve core 4, screw plug 1, etc.; one end of each hydraulic control check valve C (or C′) is connected to the inlet (or outlet) port of the cylinder, One end is connected to the system inlet (or outlet) oil circuit. During the height adjustment process, the hydraulic lock is always open, and the hydraulic control structure of the piston is shown in Figure 5 , the oil inlet pressure P3 acts on the piston, the force area is A4, the oil return pressure P4 acts on the piston (P2 is small and negligi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com