Paraffin removal shuttle

A wax removal and shuttle body technology, applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems that affect the normal production of oil wells, the reversing teeth cannot be reversing, and the elasticity of leaf springs has decreased. The effect of uniform force, reduced stress concentration, and increased area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

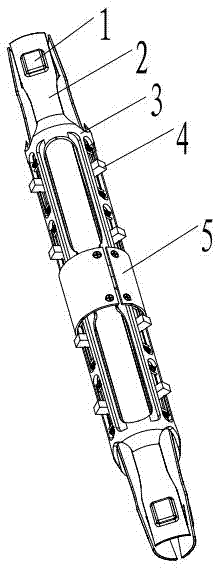

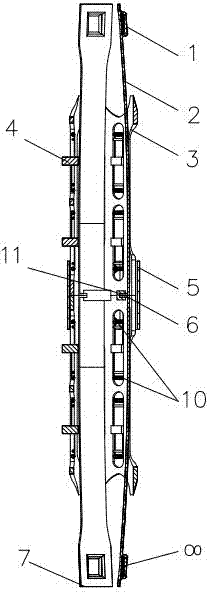

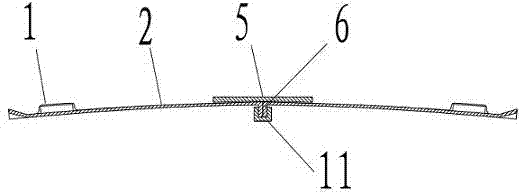

[0029] According to the attached figure 1 and attached figure 2 It can be seen that the present invention specifically relates to a wax cleaning shuttle, which is mainly used for automatically cleaning the wax deposits on the pipe wall of the oil well. There is a thrust tooth 4 in the slot hole of the tube wall of the tubular shuttle body 3, and the thrust tooth 4 is in contact with the wrap spring 2 through a spring. The L-shaped structure between the springs 2 is connected by the lap groove plate 11, so that a pair of wrap springs 2 are fixed in the length direction, the outside of the wrap spring 2 is surrounded by an annular fixing plate 5, and the fixing plate 5 and the wrapping spring 2 are surrounded by screws. The spring 2 is fixed in one piece.

[0030] In addition, a wear-resistant block 1 is provided on the free extension end of the wrap spring 2, as shown in the attached Figure 4 and 5 As shown, the wear block 1 protrudes to the outside of the tubular shuttle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com