Uniform feeding device for powdery explosive additive

A feeding device and additive technology, which is applied to explosives processing equipment, explosives, offensive equipment, etc., can solve the problems of affecting the quality of powder explosives, uneven additive addition, easy to be damp and sticky, etc., to shorten the residence time, The effect of reducing the chance of getting wet and reducing the time of exposure to steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

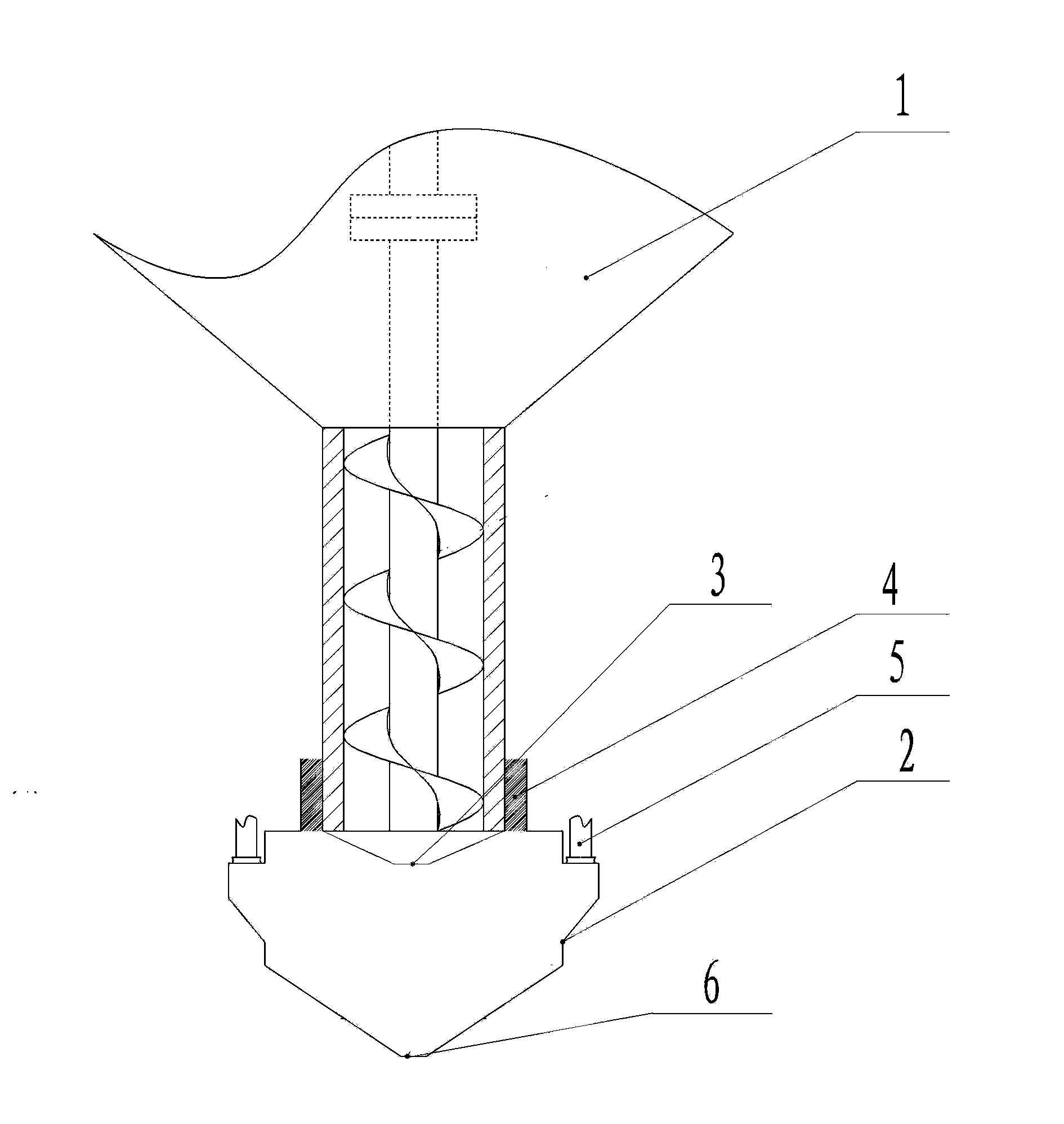

[0009] Such as figure 1 Among them, the uniform feeding device for powdery explosive additives includes a quantitative screw machine 1 and a conical nozzle 2 located at the discharge port 3 of the quantitative screw machine 1. The discharge port 3 of the quantitative screw machine 1 passes through the sealing assembly 4 and the conical nozzle 2. Connected, the conical nozzle 2 is provided with a high-pressure air intake device 5; there are two high-pressure air intake devices 5, which are horizontally and symmetrically distributed on the conical nozzle 2.

[0010] The working principle of the present invention: when the powdery explosive additive is added, the quantitative screw machine 1 quantitatively transmits the powdery explosive additive into the conical nozzle 2 through the discharge port 3, and at the same time passes the high-pressure air through the high-pressure air provided on the conical nozzle 2 The air intake device 5 is input into the conical nozzle 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com