Preparation method of multi-shape alkaline manganese phosphate microcrystal

A manganese phosphate and basic technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low product quality and complicated preparation methods, and achieve low preparation costs, simple process routes, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

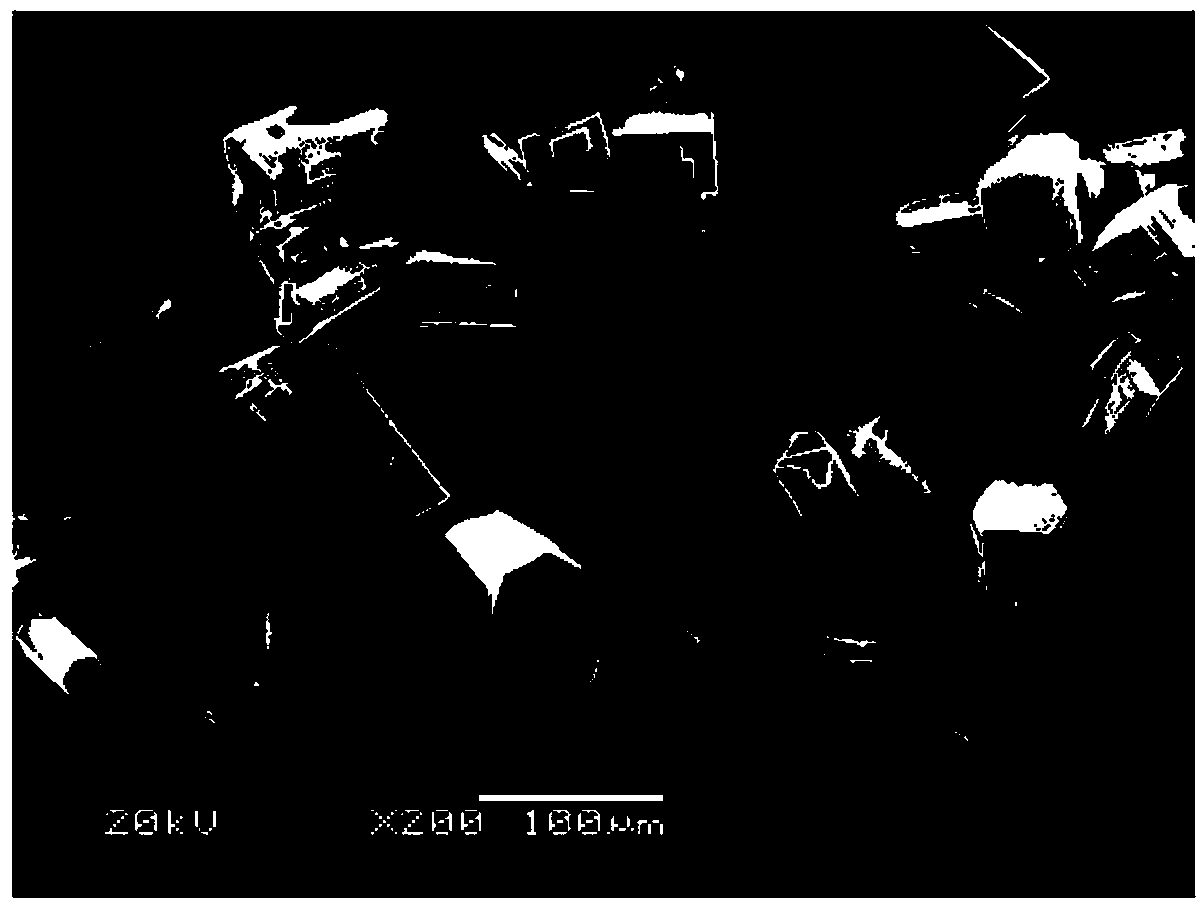

[0029] Slowly add the 0.3 mol / L manganese chloride alcohol-water mixed solution dropwise into the 0.3 mol / L diammonium hydrogen phosphate alcohol-water mixed solution. The alcohol-water mixed solution is prepared by ethanol and water according to the volume ratio of 1:20, manganese chloride / diammonium hydrogen phosphate is calculated according to the molar ratio of 1:1, and the stirring speed is 70 rpm for 30 minutes. The mixed solution obtained is carried out hydrothermal reaction, and hydrothermal reaction temperature is at 200 ℃, and hydrothermal reaction time is 24 hours. After the hydrothermal reaction is completed, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it at 150°C for 10 hours to obtain a basic manganese phosphate microcrystalline material. See SEM image diagram 2-1 and Figure 2-2 , it can be seen that the morphology of the microcrystal is a hexagonal prism, the length of the hexagona...

Embodiment 2

[0031] Slowly add the 0.1 mol / L manganese acetate alcohol-water mixed solution dropwise into the 0.1 mol / L diammonium hydrogen phosphate alcohol-water mixed solution. The alcohol-water mixed solution is prepared by ethanol and water at a volume ratio of 1:20, manganese acetate / diammonium hydrogen phosphate at a molar ratio of 1:1, and stirred and reacted at a stirring speed of 70 rpm for 30 minutes. The mixed solution obtained is subjected to hydrothermal reaction, and the hydrothermal reaction temperature is 220 ° C, and the hydrothermal reaction time is 24 hours. After the completion of the hydrothermal reaction, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it at 180°C for 10 hours to obtain a basic manganese phosphate microcrystalline material. Topography SEM image see Figure 3-1 , Figure 3-2 and Figure 3-3 , it can be seen that the morphology of the microcrystal is a flower-like morphology a...

Embodiment 3

[0033] Slowly add the 0.1 mol / L manganese nitrate alcohol-water mixed solution dropwise into the 0.1 mol / L disodium hydrogen phosphate alcohol-water mixed solution. The alcohol-water mixed solution is prepared with ethylene glycol and water at a volume ratio of 1:20, manganese nitrate / disodium hydrogen phosphate at a molar ratio of 1:2, and stirred at a stirring speed of 70 rpm for 30 minutes. The mixed solution obtained is carried out hydrothermal reaction, and hydrothermal reaction temperature is at 200 ℃, and hydrothermal reaction time is 24 hours. After the hydrothermal reaction is completed, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it at 150°C for 10 hours to obtain a basic manganese phosphate microcrystalline material. Topography SEM image see Pic 4-1 , Figure 4-2 and Figure 4-3 , it can be seen that the morphology of the microcrystal is a flower-like morphology assembled from micro-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com