Novel conveying system with sweeping device

A technology of cleaning device and conveying system, which is applied in the field of conveying system, can solve the problems such as the cleaning gap cannot be effectively controlled, the tape or conveying line is scratched, and the cleaning effect is not ideal, so as to achieve the effect of compact structure, clean conveying belt and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

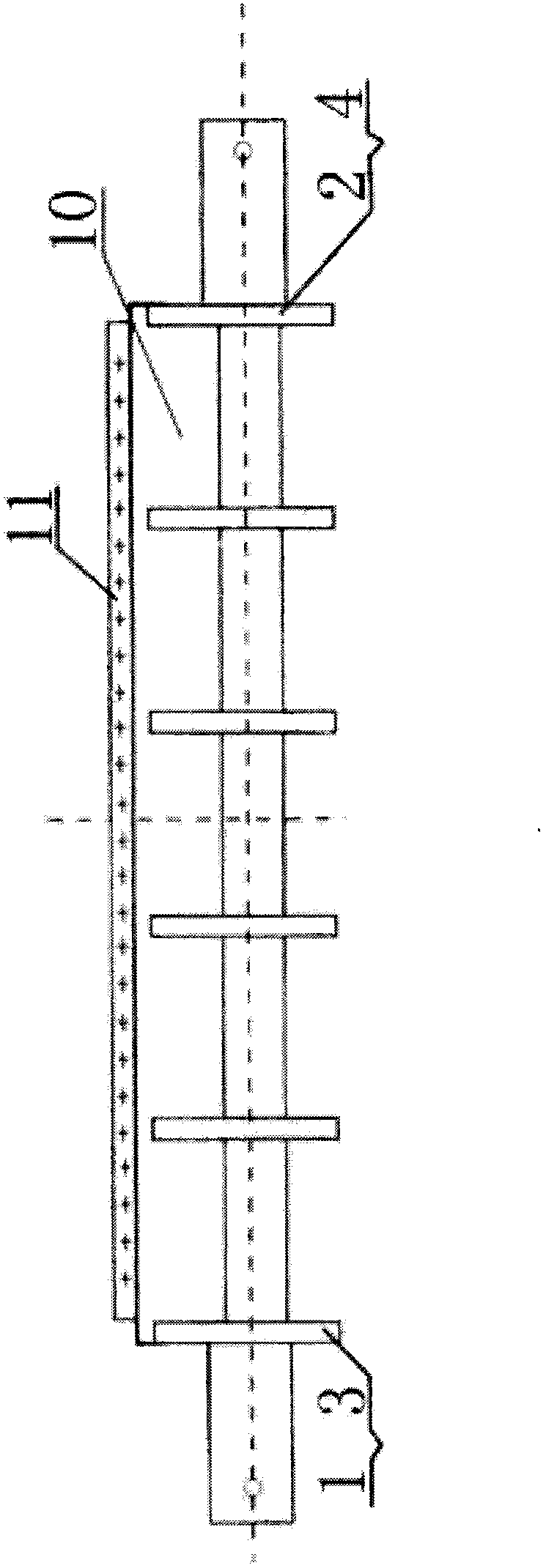

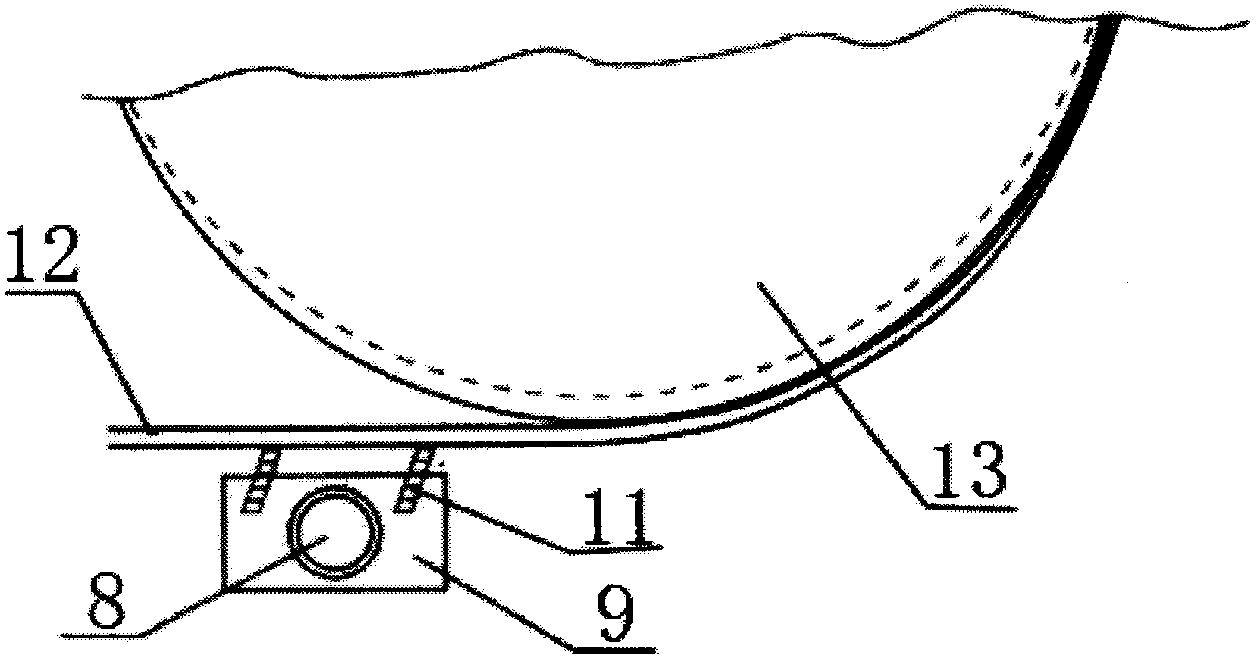

[0012] Figure 1-3 As shown, a new conveying system with a cleaning device includes a left rail plate 1, a right rail plate 2, a left bracket 3, a right bracket 4, a guide post 5, a spring 6, a half block 7, a support shaft 8, and a diaphragm 9. Scraper body 10, scraper 11, adhesive tape 12 and roller 13. The left and right brackets 3 and 4 are respectively locked in the vertical waist holes of the left and right guide rail plates 1 and 2 via bolts, and are in a vertically adjustable and fixed state on the left and right guide rail plates. The molds of the left and right brackets 3 and 4 are integrally processed Formed and equipped with guide posts 5 inside, the guide posts 5 are supported by springs 6 and connected with a half block 7, and the two ends of the support shaft 8 are respectively installed in the half blocks in the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com