Protruding object inbuilt container cover

A technology of protrusions and container caps, which is applied in the field of container caps with built-in protrusions, can solve the problems of the surface wear of protrusions, affect the visual sense, and high manufacturing cost, so as to prolong the service life, improve the ornamental quality and reduce the manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

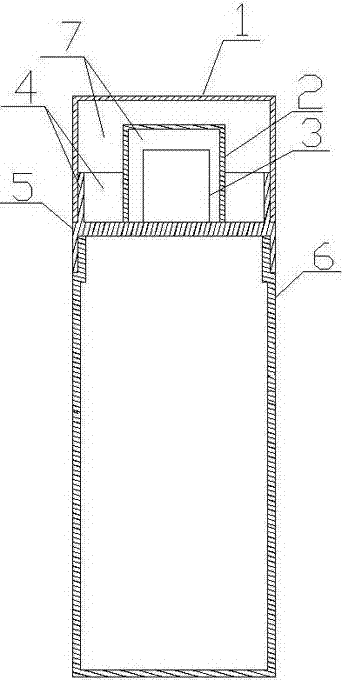

[0026] see figure 1 The present invention includes a cover body 5, which is made of a non-transparent material (such as non-transparent hard plastic), the bottom inner edge wall of the cover body 5 is provided with a connecting thread, and the cover body 5 passes through the connecting thread at the bottom Connect with the opening of the container 6 (such as a cup). The top outer edge of the cover body 5 is provided with an upwardly extending connecting pipe column 4, and a connecting thread is provided on the outer wall of the connecting pipe column 4, and the connecting pipe column 4 is threaded (also can be a buckle mode, snap In the case of buckle mode, the connecting column 4 should be provided with a card slot structure) to be movably connected to a transparent shell 1 with a bottom opening, and a cavity 7 is enclosed between the shell 1 and the top surface of the cover body 5 . A transparent liner 2 is also provided in the aforementioned cavity 7 , the liner 2 is an op...

Embodiment 2

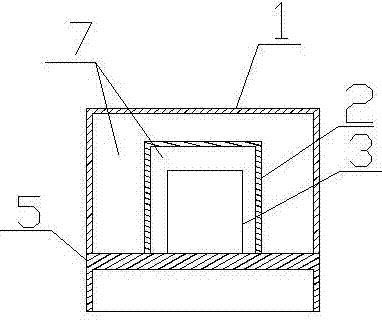

[0028] see figure 2 The present invention includes a cover body 5, which is made of a non-transparent material (such as metal), and the bottom inner edge wall of the cover body 5 is provided with a connecting thread, and the cover body 5 is connected to the container (such as a cup) by the connecting thread at the bottom. Body) opening connection. The top of the cover 5 is connected with a transparent shell 1 with an open bottom through unprinted glue. In order to improve the connection strength and enhance the aesthetic feeling, it can be considered to set a hoop at the joint between the two, and the shell 1 and the cover 5 top A cavity 7 is enclosed between the faces. A transparent liner 2 is also provided in the aforementioned cavity 7 . The liner 2 has an open bottom structure, and the bottom end of the liner 2 is bonded to the top surface of the cover body 5 surrounded by the housing 1 through unprinted glue. In the cavity 7 formed by the inner tank 2 and the top surfa...

Embodiment 3

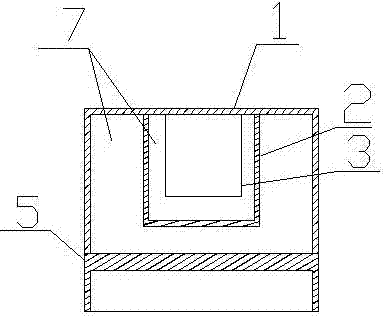

[0032] see image 3 The present invention includes a cover body 5, which is made of a non-transparent material (such as metal), and the bottom inner edge wall of the cover body 5 is provided with a connecting thread, and the cover body 5 is connected to the container (such as a cup) by the connecting thread at the bottom. Body) opening connection. A transparent casing 1 with an open bottom is bonded on the top of the cover body 5 by unprinted adhesive, and a cavity 7 is enclosed between the casing 1 and the top surface of the cover body 5 . A transparent liner 2 is also provided in the aforementioned cavity 7. The liner 2 has an open top structure, and the top of the liner 2 is bonded to the inner top surface of the housing 1 by unprinted glue, and the liner 2 is inverted. shape. There is a protrusion 3 in the cavity 7 formed by the inner liner 2 and the shell 1, the protrusion 3 is carved from glass, and the protrusion 3 is bonded to the inner top surface of the shell 1 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com