Manufacturing method of plastic floor tile

A manufacturing method and technology of floor tiles, which are applied in the field of manufacturing plastic floor tiles, can solve problems such as not being able to satisfy high-end consumers, and achieve the effects of tight adhesion, streamlined production processes, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiment of the manufacturing method of the plastic floor tile of the present invention is further described below. Please refer to the relevant drawings and descriptions. In order to facilitate the understanding of the embodiments of the present invention, the same components are described below with the same symbols.

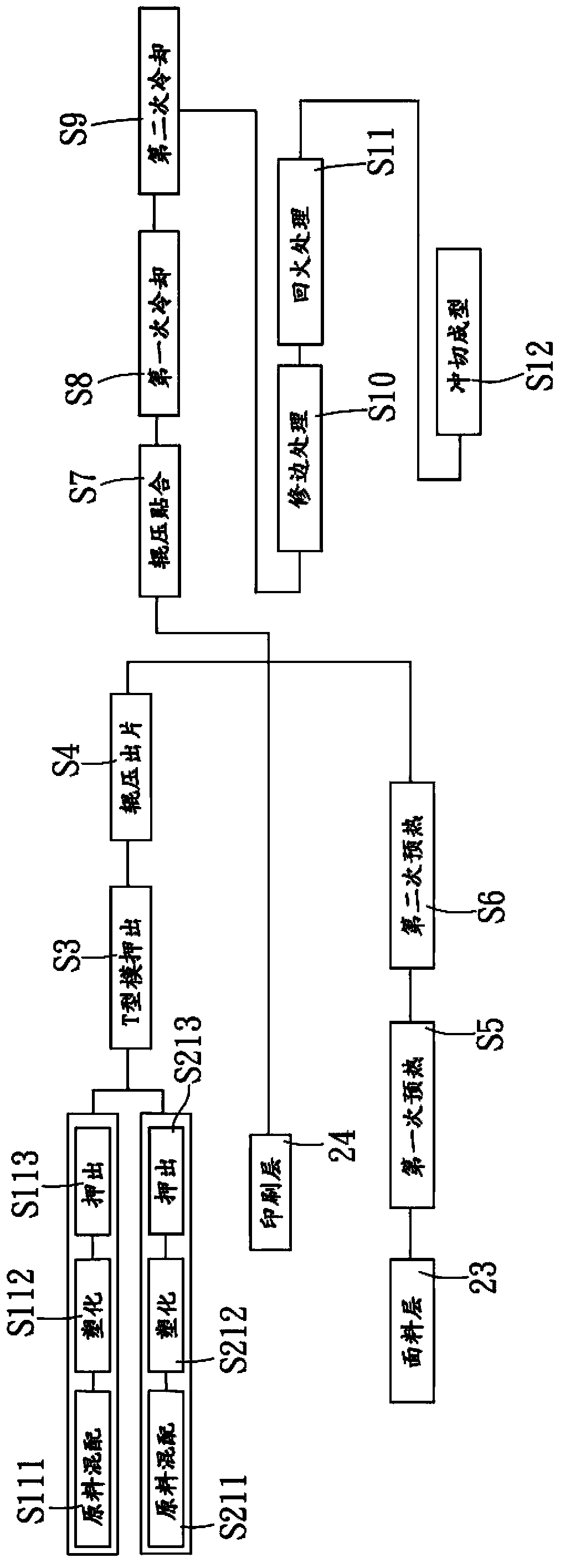

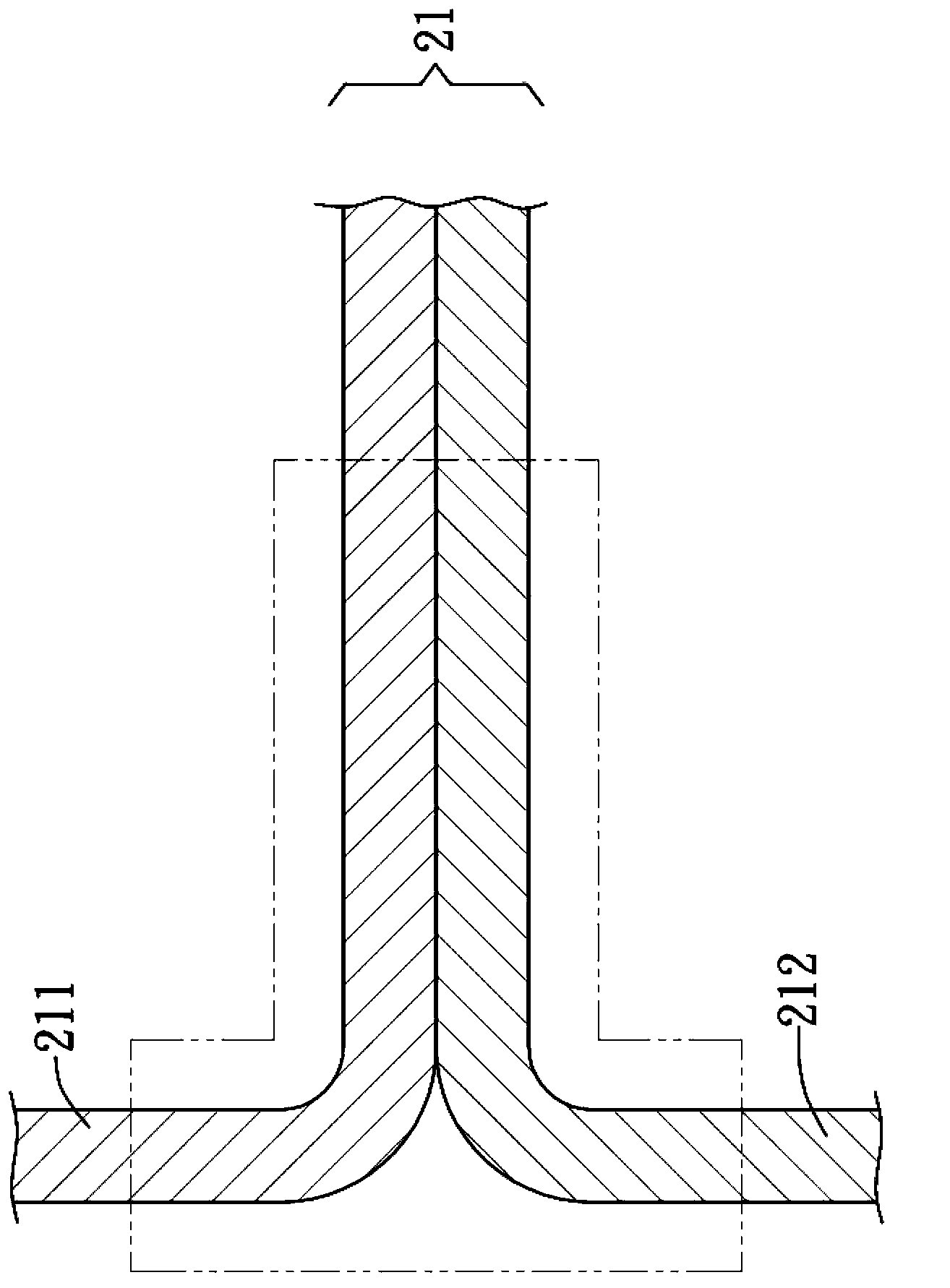

[0040] see figure 2 and Figure 5 as shown, figure 2 It is the schematic flow chart of the manufacturing method of the plastic floor tile of the present invention, image 3 It is the schematic diagram of the T-type mold extrusion embodiment of the manufacturing method of the plastic floor tile of the present invention, Figure 4 It is the schematic diagram of the embodiment of the manufacturing method of the plastic floor tile of the present invention and Figure 5 It is a schematic cross-sectional view of the finished product of the manufacturing method of the plastic floor tile of the present invention. In the figure, the manufacturing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com