Grinding wheel dressing mechanism with position-adjustable dresser

A grinding wheel dressing and dresser technology, which is applied to the parts of grinding machine tools, abrasive surface adjustment devices, metal processing equipment and other directions, can solve the problems of inconvenient processing, inability to dress the grinding wheel, low work efficiency, etc., and achieves good dressing effect. Reasonable structural design and large-scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

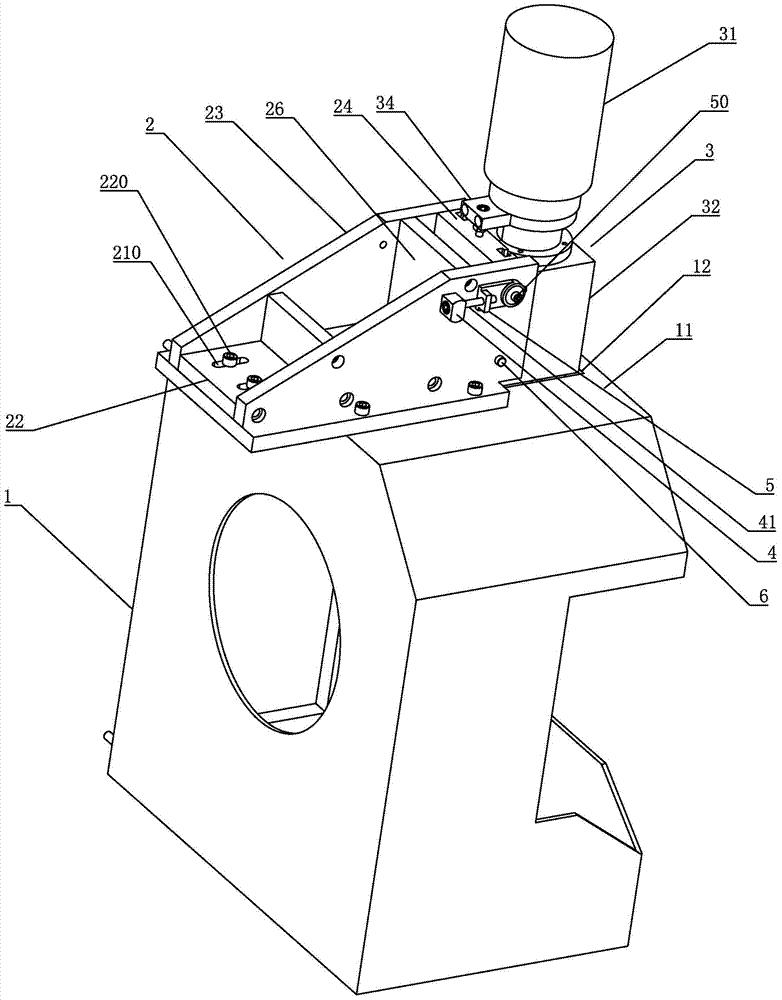

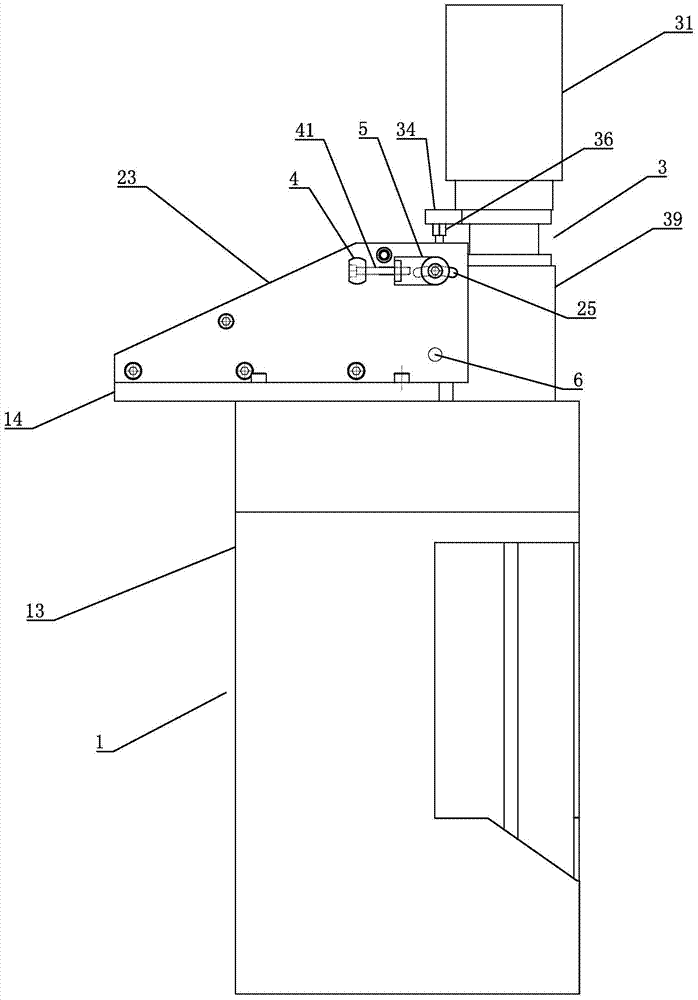

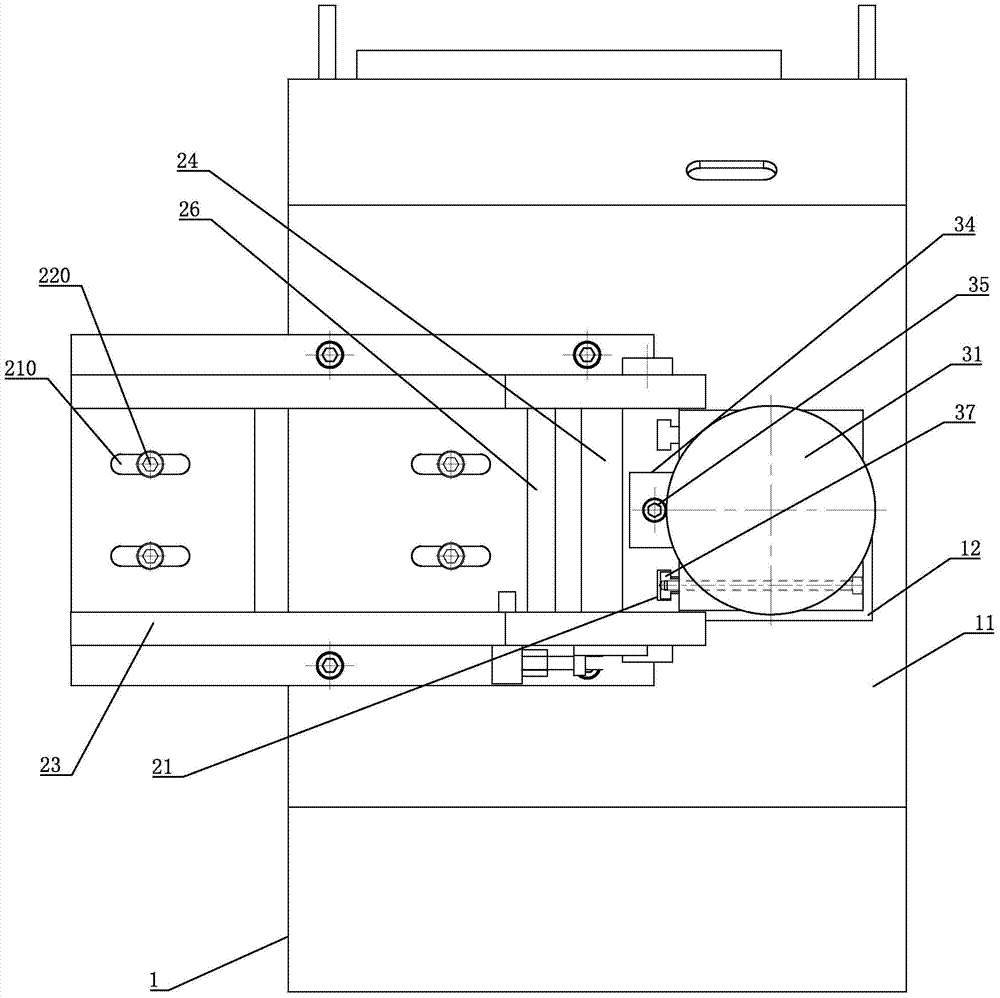

[0022] Such as Figure 1~Figure 5 As shown, a grinding wheel dressing mechanism with adjustable position of the dresser includes a dresser mounting base 1, and the dresser mounting base 1 includes a top plate 11, and the dresser adjusting base 2 is received on the dresser mounting base 1. A strip-shaped hole 210 is provided on the trimmer adjusting seat 2 , and a first bolt 220 is threaded through the strip-shaped hole 210 , and the trimmer 3 adjuster is fixed on the trimmer mounting seat 1 through the first bolt 220 . As a preference of the present invention, the trimmer mounting base 1 includes a base 13 and a horizontal plate 14, the horizontal plate 14 is located between the top plate 11 and the trimmer adjustment seat 2, the horizontal plate 14 is fixedly connected to the base 13, and the horizontal plate 14 is provided with a first threaded hole corresponding to the first bolt 220; the trimmer adjustment seat 2 includes a horizontally arranged bottom plate 22 and a verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com