Installing hole punching device

A stamping device and mounting hole technology, applied in the field of stamping dies, can solve the problems of die damage, production efficiency reduction, plate 90 scrapping, etc., and achieve the effects of preventing accumulation, ensuring accuracy and reducing burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

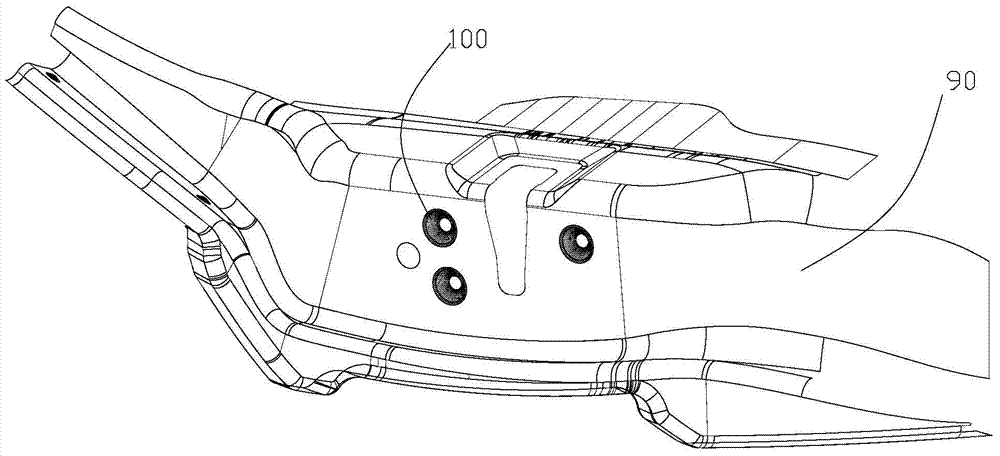

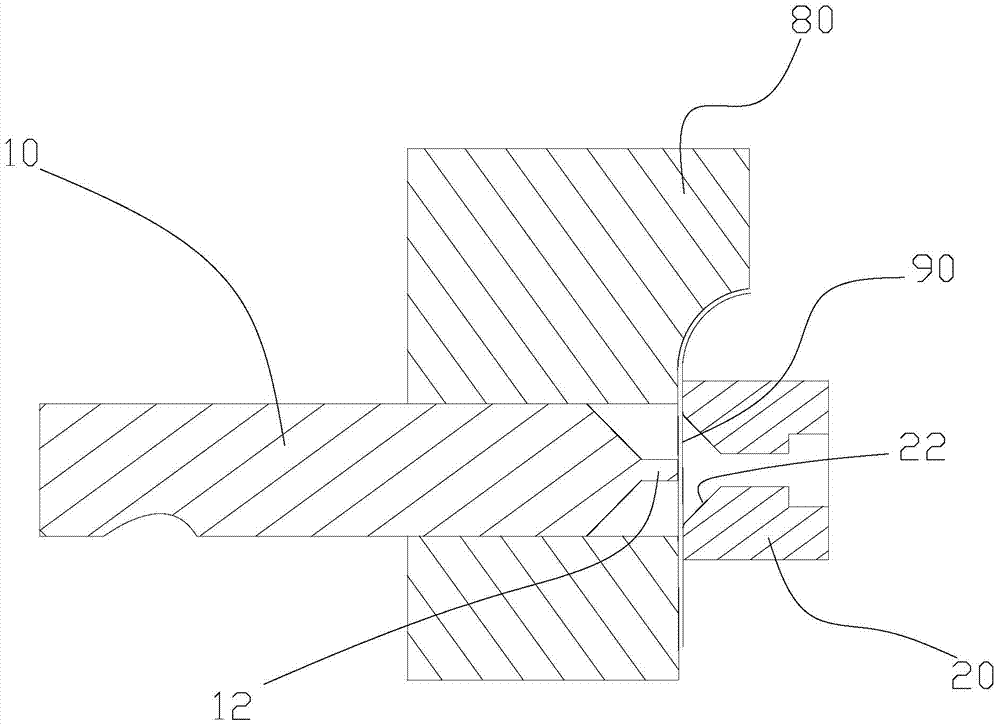

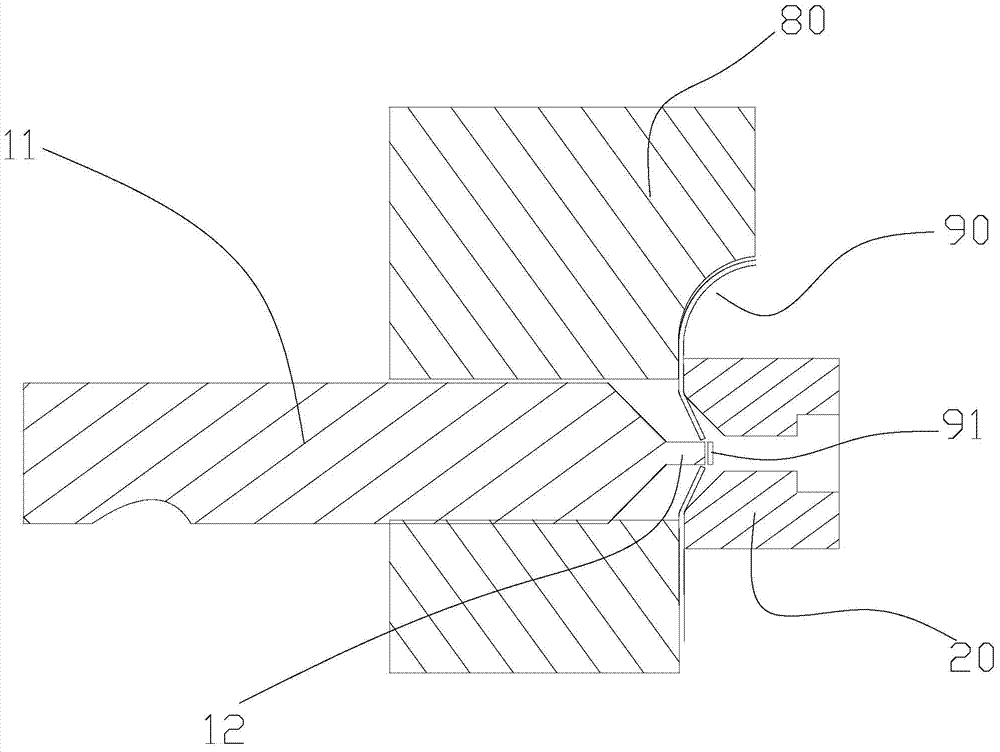

[0055] Such as Figure 7 As shown, a mounting hole punching device of the present invention includes a punch 10 , a die button 20 , a movable block 30 and an elastic member 40 . Wherein, the punch 10 includes a punch rod 11 and a punching head 12, the punch rod 11 is used for connecting with a power source so that the punch head 10 shown can move, and the punch head 12 is used for punching the plate 90 punching. Figure 8 yes Figure 7 The assembly schematic diagram of the mounting hole punching device shown is also a schematic diagram of the working state of the mounting hole punching device. Such as Figure 8 As shown, the mold button 20 is in conflict with the plate 90 , so that the mold button 20 is matched with the punch 10 to punch out the installation hole 100 on the plate 90 . Stamping here includes punching and flanging. Such as Figure 8 In the working state shown, the movable block 30 is arranged in the mold button 20 and the front end is in conflict with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com