Easily-operated type recoilless underwater cavitation cleaning spray gun

An easy-to-operate, nozzle-cleaning technology, applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of cleaning effect and efficiency difference, spray gun operability and safety impact, etc., to increase operational safety and improve Operability and stability, the effect of increasing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] This embodiment provides an easy-to-operate recoilless underwater cavitation cleaning spray gun. The spray gun has a good cleaning effect and is in a recoilless state during use with strong operability.

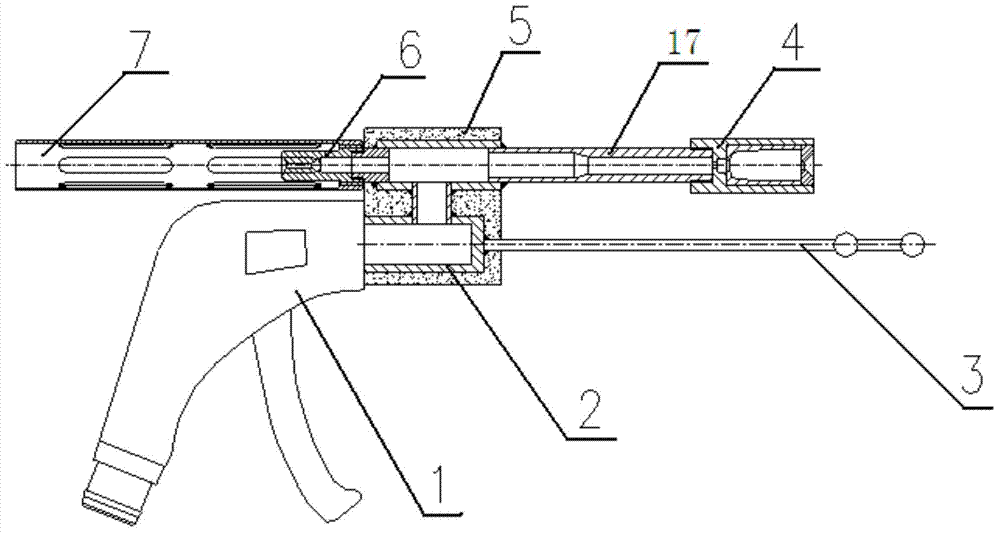

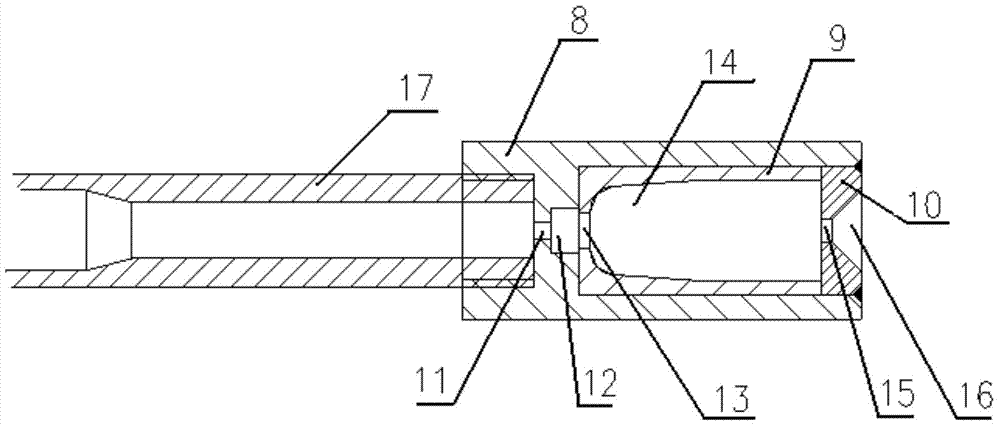

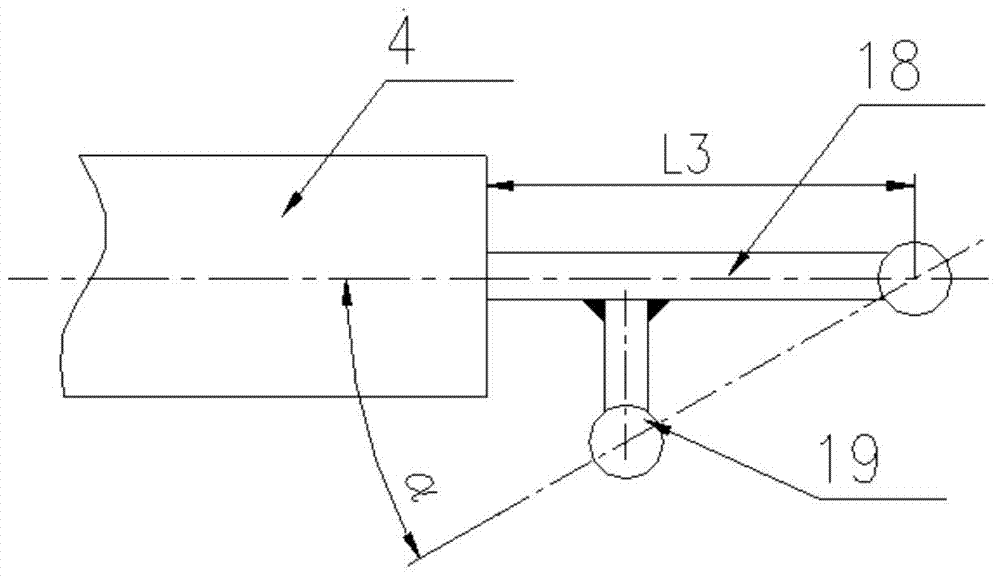

[0031] The structure of the cleaning spray gun is as follows: figure 1 As shown, it includes a gun handle 1, a spray gun connector 2, a positioning tool 3, a cavitation cleaning nozzle 4, a steady flow pipe 17, an anti-spray nozzle 6 and an unloading protection pipe 7. In this embodiment, the spray gun connecting body 2 is an "I-shaped" structure welded by three sections of hollow cylinders, and its central hole runs through to transport high-pressure liquid. Wherein the open end of the horizontal hollow cylinder located below is threadedly connected to the gun handle 1, and the end of the gun handle 1 is equipped with a quick-change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com