Wafer assembly system

An assembly system and wafer technology, applied in transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of low assembly efficiency, high work intensity, high product defect rate, and achieve the effect of positioning and high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

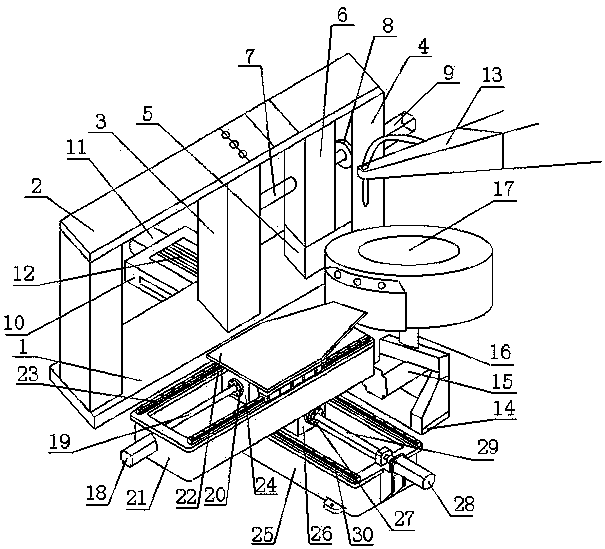

[0022] Such as figure 1 As shown, the wafer assembly system includes a lead wire longitudinal translation assembly, a lead wire lateral translation assembly, a worktable movement assembly, a wafer tray positioning assembly, a wafer tray X-axis translation assembly, a wafer tray Y-axis translation assembly and a wafer loading and unloading robot 13, and the lead wire The longitudinal translation component drives the workbench movement component to move longitudinally, thereby causing the leads on the worktable 2 to translate longitudinally, and the lead transverse translation component is used to realize the lateral translation of the leads, thereby realizing the self-positioning welding of the chip. During the wafer self-positioning suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com