Intelligent Control System of Water Chillers Used in Coal Mine

A chiller and control system technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems that cannot fully realize intelligent and economical operation, and achieve low and high efficiency in heat dissipation and energy efficiency utilization Cooling down the mine and solving serious waste effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

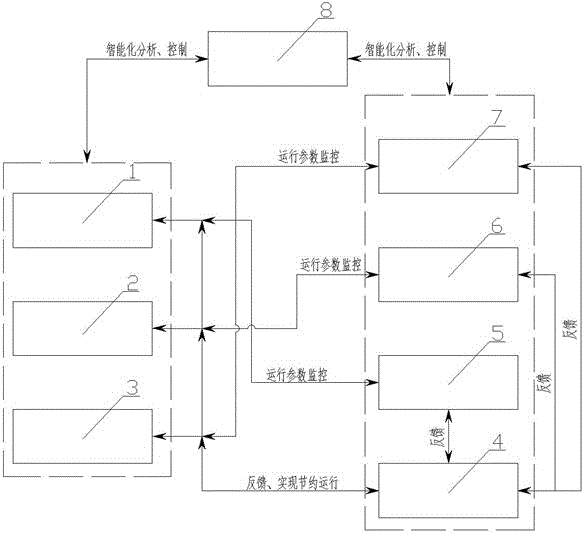

[0017] see figure 1 , the control system consists of an intelligent control console for mining chillers 4, a visualization and saving display platform for operating parameters of mining chillers 5, an energy efficiency analysis and operating parameter visualization platform for mine mobile air coolers 6, and a mine mobile Water cooler energy efficiency analysis and operating parameter visualization platform7 and mine heat damage control effect feedback platform8. The feedback platform 8 of mine heat hazard control effect is connected with the mining chiller 1, the mine air cooler 2, and the mine water cooler 3, and is connected with the intelligent control console 4 of the mine chiller and the saving display platform 5 , operating parameter visualization platform 6, and operating parameter visualization platform 7 are connected, wherein the mine chiller 1 is connected with the saving display platform 5, the mine air cooler 2 is connected with the operating parameter visualizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com