Automatic detection line and detection method for pole piece defects of power lithium-ion batteries

A lithium-ion battery, automatic detection technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of high cost and large standard fluctuation, and achieve the effect of improving efficiency, avoiding damage and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

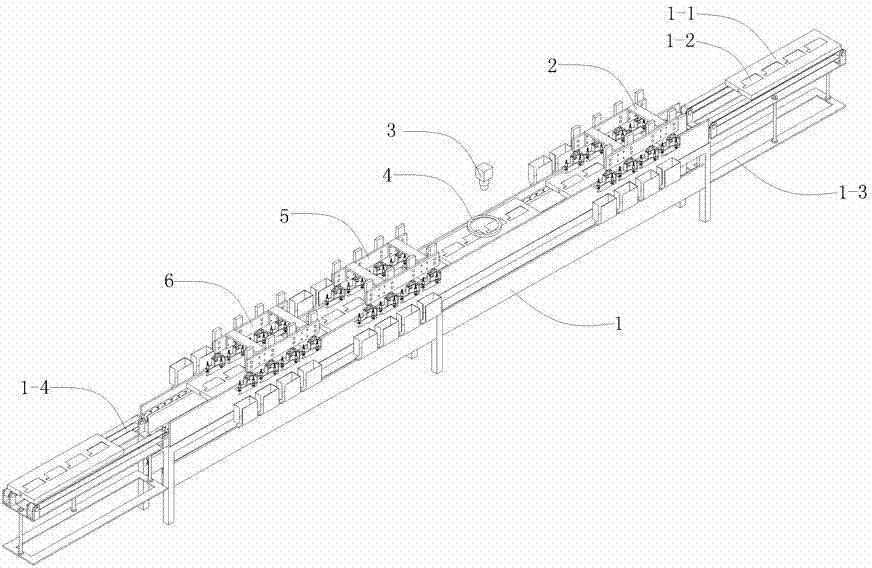

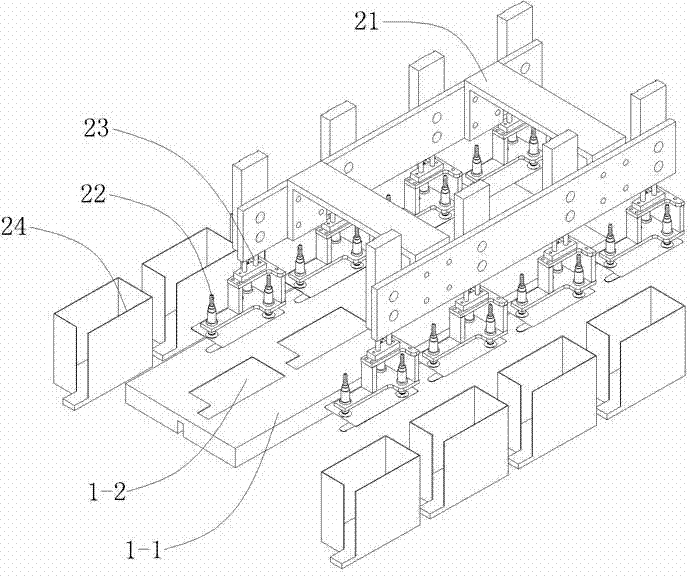

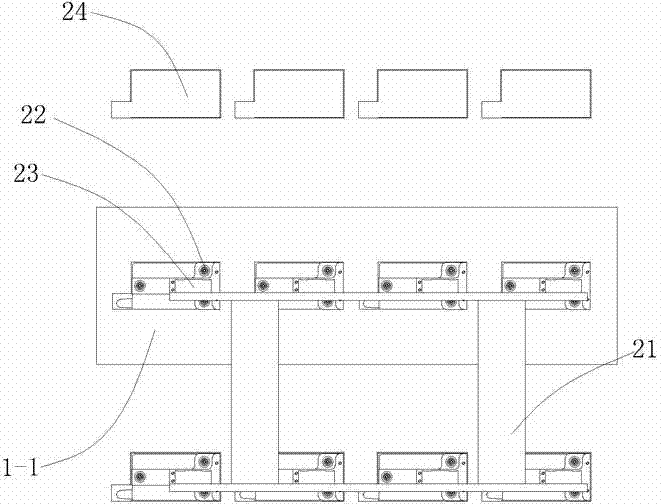

[0029] Example: such as figure 1As shown, the automatic detection line for pole pieces of power lithium-ion batteries in this embodiment includes a feeding mechanism 2 arranged along the running direction of the tooling plate 1-1 on the double-speed chain 1, a visual inspection mechanism, a qualified product unloading mechanism 5, and a disqualified product. Product unloading mechanism 6, and control mechanism.

[0030] For the feeding mechanism, the unqualified product unloading mechanism and the unqualified product unloading mechanism, since they have the same structure, the first beam, the second beam, and the third beam are collectively referred to as beams below, and the first lifting mechanism, the second The second lifting mechanism and the third lifting mechanism are collectively referred to as the lifting mechanism, and the first translation mechanism, the second translation mechanism, and the third translation mechanism are collectively referred to as the translation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com