Multi-point in-situ stress test method of soft rock using connecting rod

A test method and connecting rod technology, applied in the direction of measuring force, measuring the force by measuring the frequency change of the vibrating element under stress, and measuring devices, can solve the problems of difficult implementation of stress relief method and obtain mechanical parameters, etc., and achieve calculation Simple and stable, uniform slurry medium, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

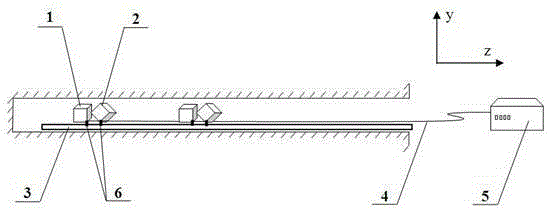

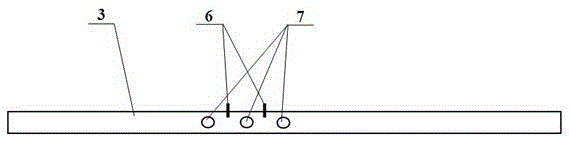

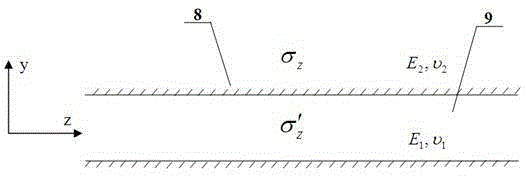

[0039] For the sandstone coal-measure stratum with high strength and hard texture with a depth of 800-1000 meters, firstly make the connecting rod 3 in the form of sections, which are made of hollow ordinary steel pipes, each connecting rod is 120cm long, and each connecting rod 3 All can be threaded with other connecting rods 3, and the inside and outside are smooth. In the middle of a part of the connecting rod 3, there are two locking screws 6 that can be connected with the screw holes on the three-way pressure boxes 1 and 2. The connecting rod 3 is machined with three bolts on the outer and middle positions of the two locking screws 6. Pulp hole 7.

[0040] When used in 800-1000 meters deep soft rock roadway in coal mine, the roadway diameter is about 4 meters, the drilling depth is 20-30 meters, and the hole diameter is 130mm. Select the connecting rod 3 with the locking screw 6, and securely connect the three-way pressure boxes 1 and 2 to it to ensure that the normals o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com