Yarn drying device

A drying device and yarn technology, applied in progressive dryers, drying solid materials, drying, etc., can solve problems such as inability to realize automatic control and deployment, uneven drying of yarns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

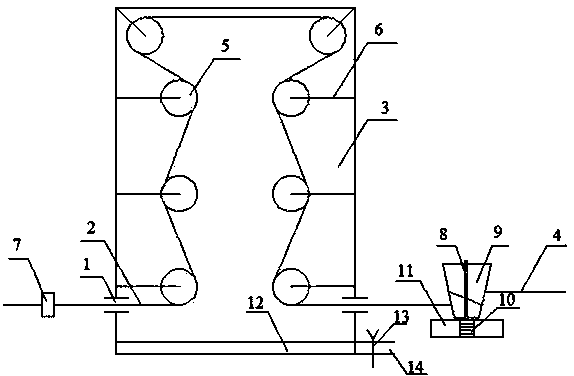

[0014] Such as figure 1 As shown, the yarn drying device of the present invention includes an oven 3, a yarn inlet 1 located on the side wall of the oven 3, and a yarn outlet 4 located on the opposite side of the yarn inlet 1; A positioning frame 7 is installed, and a lead roller 6 is mounted on the positioning frame 7 . The wet yarn 2 enters the oven 3 from the yarn inlet 1, moves at a constant speed in the oven 3 through the lead roller 6, and finally moves to the yarn outlet 4 to output the yarn. A humidity detector 8 is provided before the yarn inlet 1, and a yarn traction device is provided after the yarn outlet 4; the yarn traction device includes a pulling roller 10, a rotating shaft 9, a motor 11 and a base 12; The motor 11 is placed on the base 12, the rotating shaft 9 is driven by the motor 11, and the wire pulling roller 10 is installed in cooperation with the rotating shaft 9; the humidity detector 8 and the motor 11 are all electrically connected to the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com