Cycloidal pin wheel speed reducer

A pin wheel reducer, cycloid technology, applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., can solve the problem that the reducer does not directly realize fixed-axis transmission, the radial size of the reducer is large, and the Increase the axial size of the reducer and other issues to achieve the effect of compact structure, improved bearing capacity, and enlarged bearing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

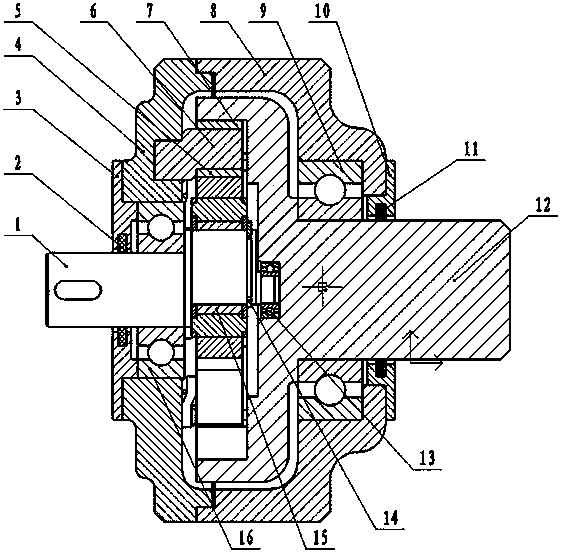

[0024] Such as figure 1 As shown, the input shaft 1 is an eccentric shaft, and a needle roller bearing 15 without an outer ring is installed on the outside of the shaft. One end of the input shaft 1 is provided with a support bearing 13, and the other end is provided with an input end support bearing 16.

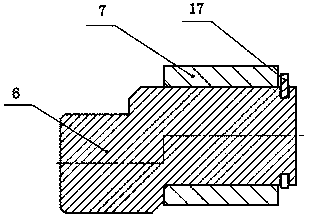

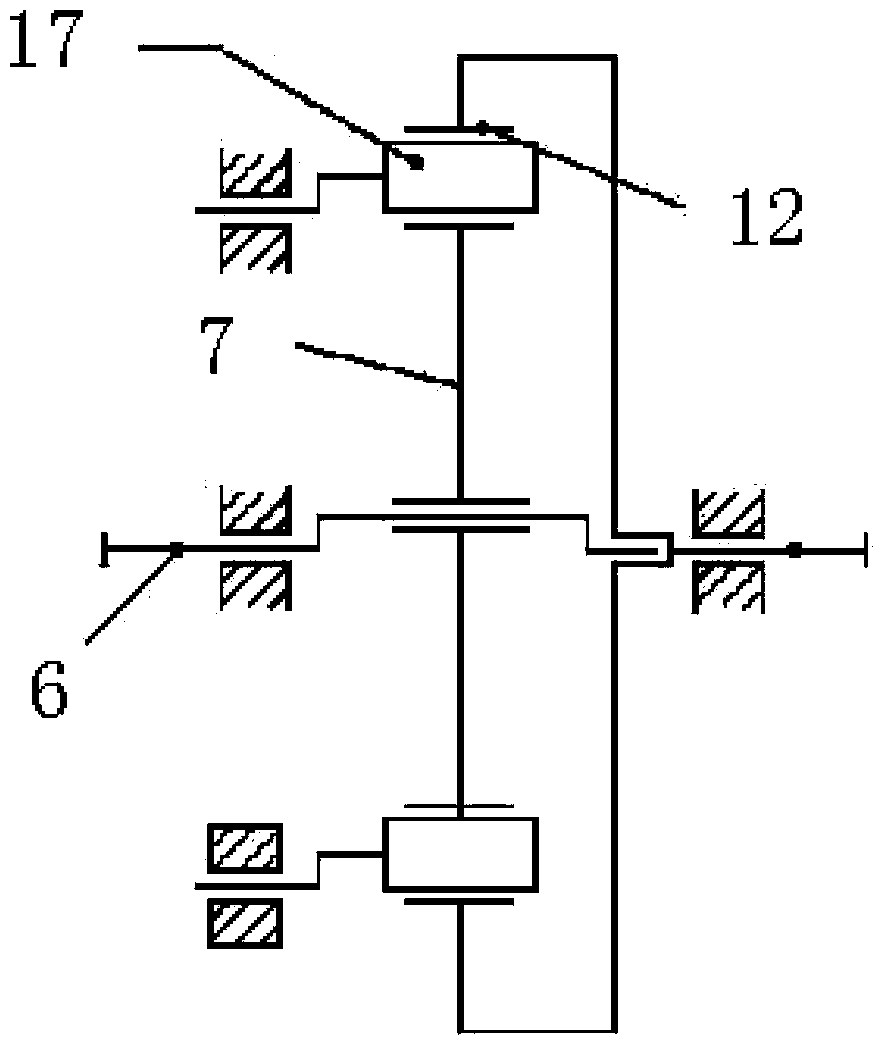

[0025] Pin teeth 6 are engaged with the outside of the above-mentioned epicycloid wheel 5 , and pin teeth copper sleeves 7 are installed outside the pin teeth 6 .

[0026] Such as figure 2 As shown, the pin teeth 6 are eccentric pin teeth, one end of the pin teeth 6 is covered with a pin tooth copper sleeve 7, and the end of the copper sleeve 7 is installed with a retaining ring 17 for the shaft. Corresponding tooth-shaped structures are processed on the inner and outer walls of the pin-toothed copper sleeve 7 , so the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com