A can aluminum alloy plate and a manufacturing method thereof

A technology of aluminum alloy plate and aluminum alloy, which is applied to the aluminum alloy plate for tank body and its manufacturing field, can solve the problems such as the reduction of the strength of the tank body, and achieve the effect of reducing the strength of the tank body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

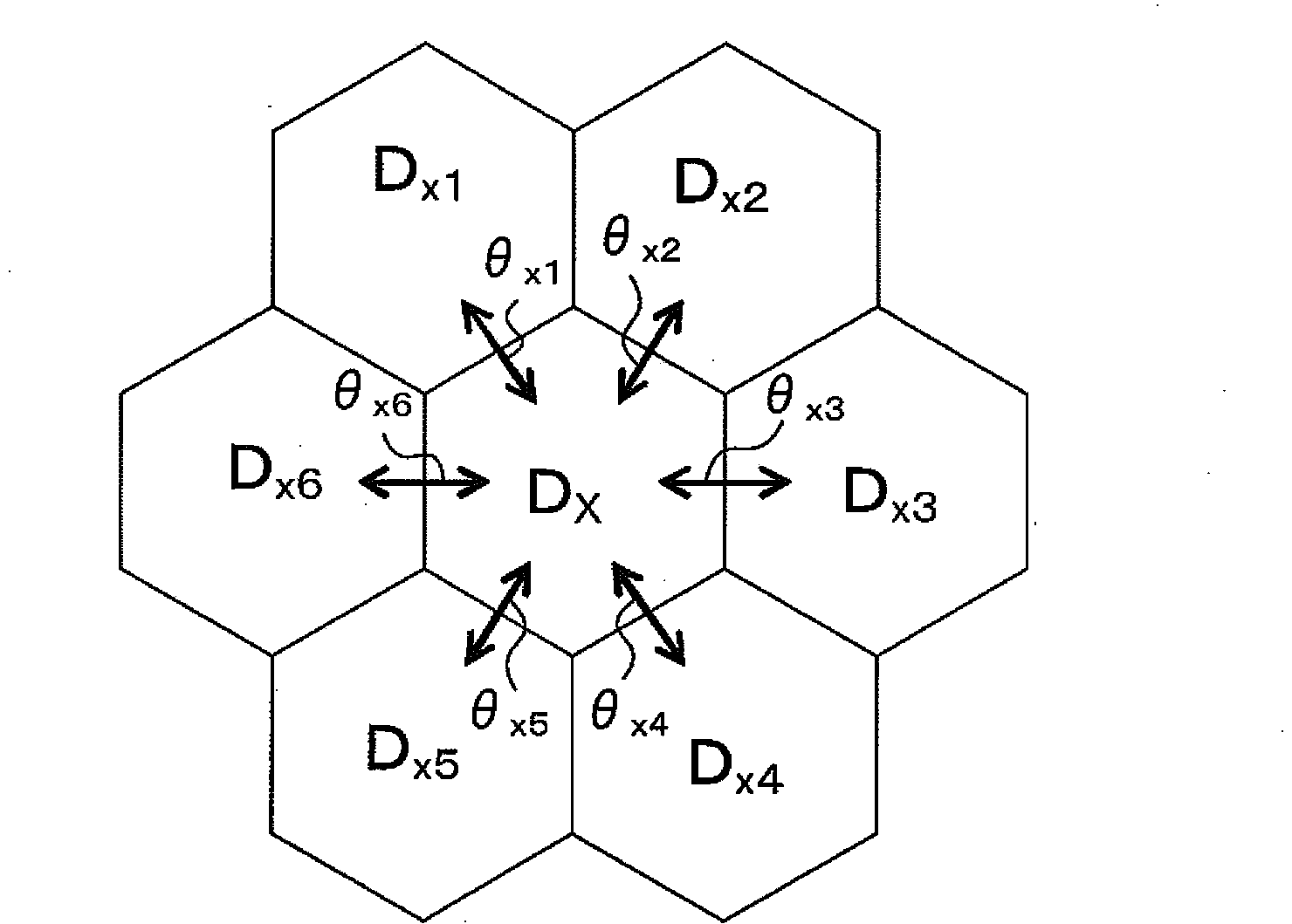

Image

Examples

Embodiment 1

[0058] 1. Manufacture of aluminum alloy plate for tank body

[0059] Aluminum alloys A1 to A10 having the composition shown in Table 1 were melted by a conventional method, and were semi-continuously cast to produce aluminum alloy ingots.

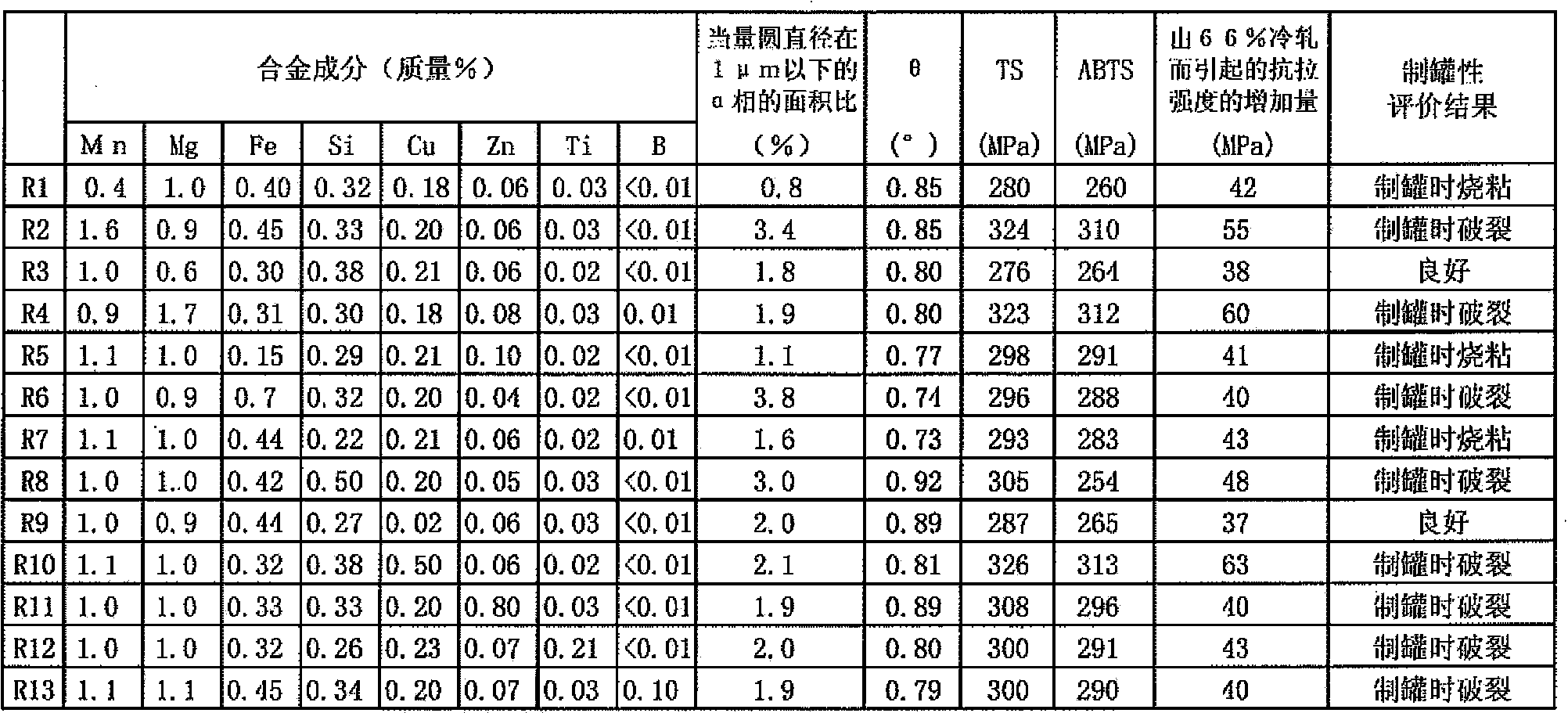

[0060] 【Table 1】

[0061]

[0062] The obtained aluminum alloy ingot was subjected to a homogenization treatment at a temperature of 600° C. for 10 hours in an air furnace. Thereafter, it is cooled to the hot rolling start temperature with a heat history of 350 to 480 (°C·h) on the left side of the above formula (1). The hot rolling start temperature was 490°C.

[0063] Next, from the initial pass to the final pass, hot rough rolling for rolling the plate to a thickness of 30 mm was performed under the condition that the cumulative holding time in the temperature range of 450 to 500° C. was 350 to 490 seconds. And hot finish rolling which rolled the plate thickness to 2.4 mm was performed on the condition of the outlet side temperatur...

Embodiment 2

[0100] Using the component composition of A9 in Example 1, under the production conditions shown in Table 3, aluminum alloy plates for can bodies of B1 to B7 were produced. Also, the basic manufacturing method is the same as in Embodiment 1 described above.

[0101] 【table 3】

[0102]

[0103] In addition, the final plate thickness of the hot rough rolling was 30 mm, and the final plate thickness of the hot finish rolling was 2.4 mm. In addition, when the number of passes of cold rolling was 3, the final plate thickness was 0.28 mm. In addition, the outlet side temperature of the final pass of cold rolling was 145 to 155°C.

[0104] Test materials were produced for the aluminum alloy plates for can bodies of B1 to B7, respectively, and the same evaluations as in Example 1 were performed. The evaluation results are shown in Table 3 above.

[0105] As shown in Table 3, the aluminum alloy sheets for can bodies of B1 to B7 were not too high in tensile strength (TS) in the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com