Novel aluminum alloy car anti-collision beam

A technology of aluminum alloy and anti-collision beams, applied in the direction of bumpers, etc., can solve the problems of not meeting the requirements of trailers, not meeting the requirements of energy saving and environmental protection, and the single function of anti-collision beams, and achieve the effect of light weight, multiple functions and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments. The given embodiments are only general illustrations of the products or methods of the present invention, which help to better understand the present invention, but do not limit the scope of the present invention. The experimental methods described in the following examples, unless otherwise specified, are conventional methods; the materials, unless otherwise specified, can be obtained from commercial sources.

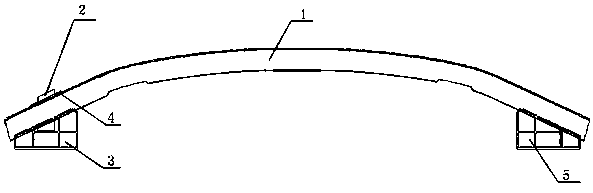

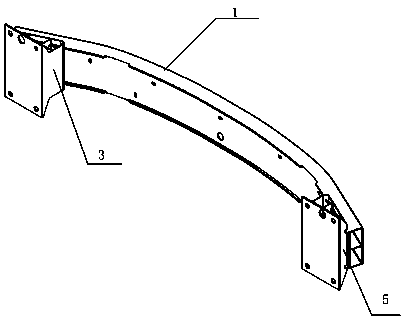

[0013] like figure 1 As shown, a novel aluminum alloy automobile anti-collision beam of the present invention includes a beam 1 and a left energy-absorbing box 5 and a right energy-absorbing box 2 symmetrically arranged on both sides of the beam 1, a left energy-absorbing box 5 and a right energy-absorbing box 2 is fixed by welding with beam 1. At the position adjacent to the left energy-absorbing box 5 or the right energy-absorbing box 2, a tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com