High-strength austenitic stainless steel submerged-arc welding wire

An austenitic stainless steel, high-strength technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve problems such as insufficient mechanical properties of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below through embodiment.

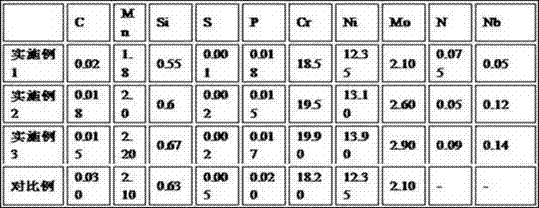

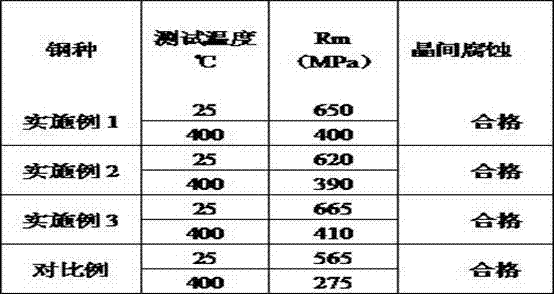

[0033] The chemical composition of the welding wire of the present invention and the tensile strength of the welded joint are listed in Table 1 and Table 2 respectively. The welded joint of the austenitic stainless steel welding material of the present invention has excellent high temperature strength and can be used for welding of pressure vessel equipment under high temperature or fix.

[0034] The test uses four kinds of welding wires to be prepared by the same production process. The diameter of the welding wire is 2.5mm, the supporting welding is SJ601H, the welding base metal is 316L (N), the welding process parameters are: arc voltage 28V, welding current 400A, welding speed 300mm / min, the mechanical properties and corrosion resistance of the deposited metal were measured after welding. Among them, the corrosion resistance is in accordance with the sulfuric acid-copper sulfate standard i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com