Extrusion die of press pipe fitting

The technology of pressing pipe fittings and ring pressing die is applied in the field of ring pressing moulds of pressing pipe fittings, which can solve the problems of insufficient crimping of pipe fittings and affecting the crimping effect of pipe fittings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

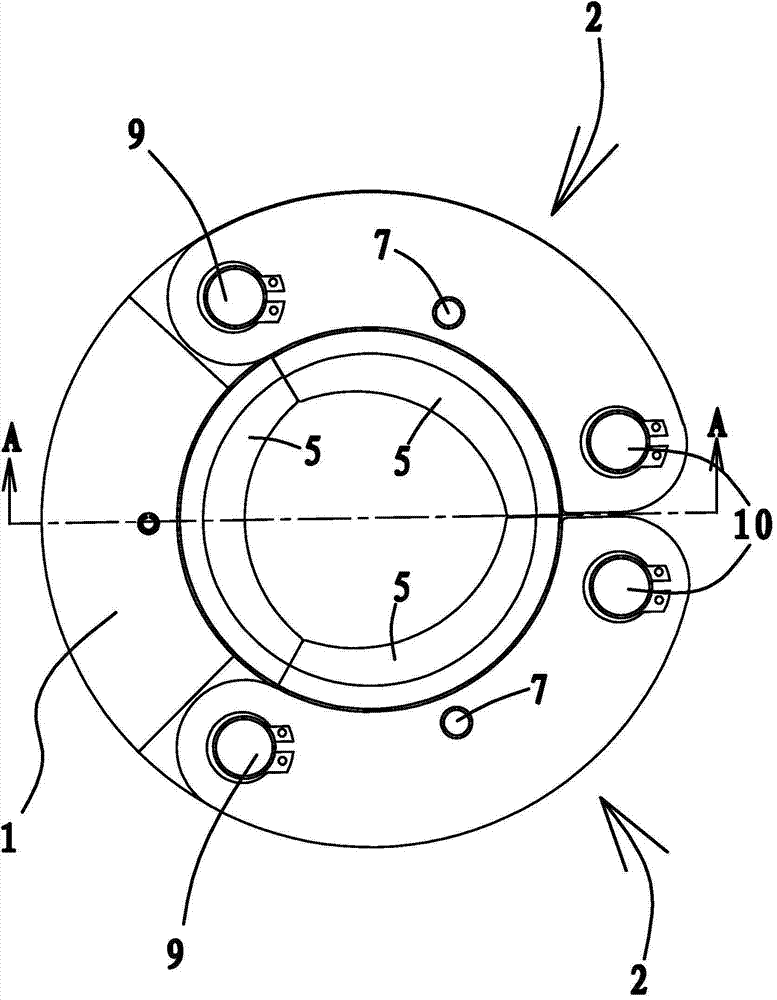

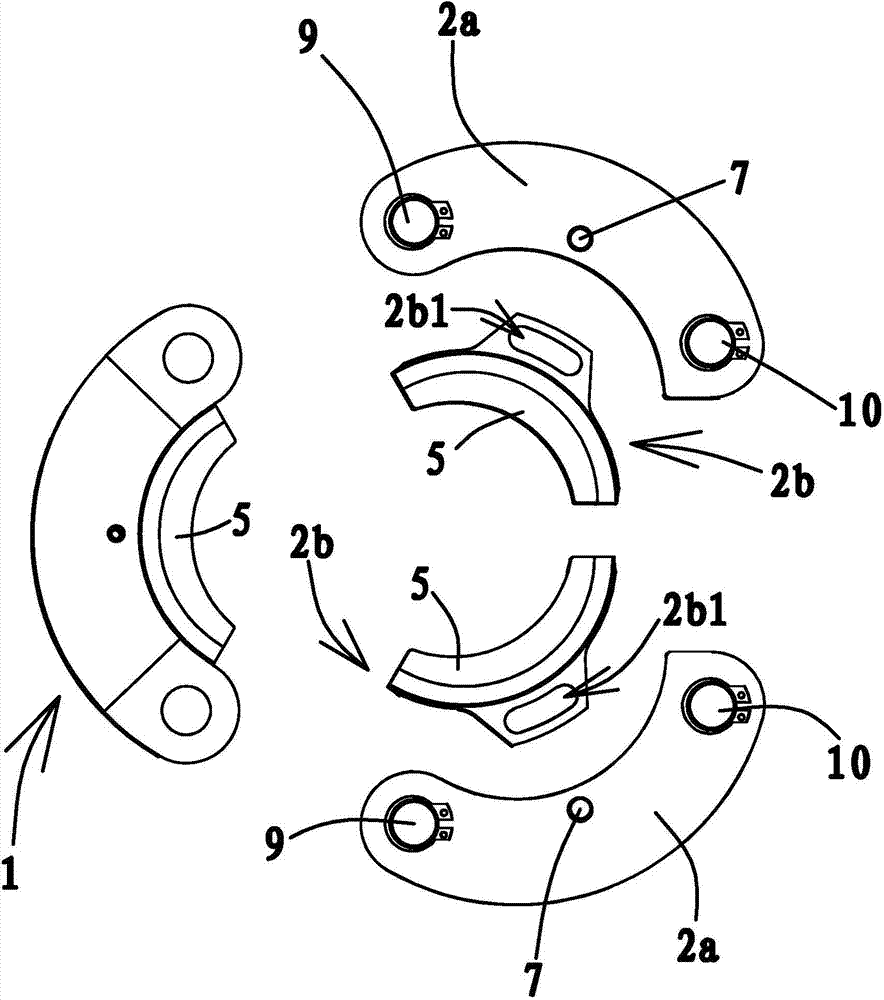

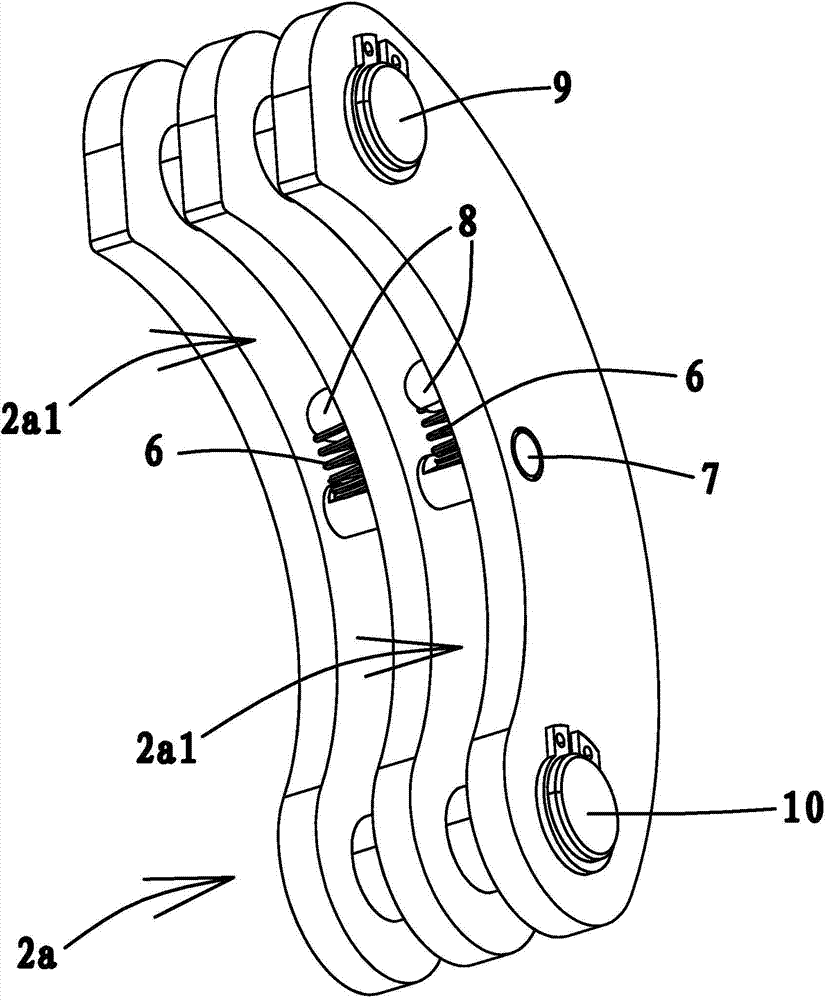

[0028] Such as Figure 1 to Figure 2 As shown in the figure, the ring pressing mold of the clamping type pipe fitting includes a circular arc-shaped fixed mold 1 and two circular arc-shaped movable molds 2 . Both ends of the fixed mold 1 and the movable mold 2 have through holes. The two through holes of the fixed mold 1 are provided with hinged columns 9, and the through holes at one end of the two movable molds 2 respectively pass through the two hinged columns 9, so that the two movable molds 2 are hinged at both ends of the fixed mold 1 . The other ends of the two movable molds 2 are fixedly connected with clamping columns 10. When the pipe fittings are crimped, the hydraulic jaws 3 act on the two clamping columns 10 on the two movable molds 2, and the two movable molds 2 pass through The hydraulic jaws 3 are snapped together to crimp the pipe fittings.

[0029] The outer ends of the two movable molds 2 can be fastened together, and when they are fastened together, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com