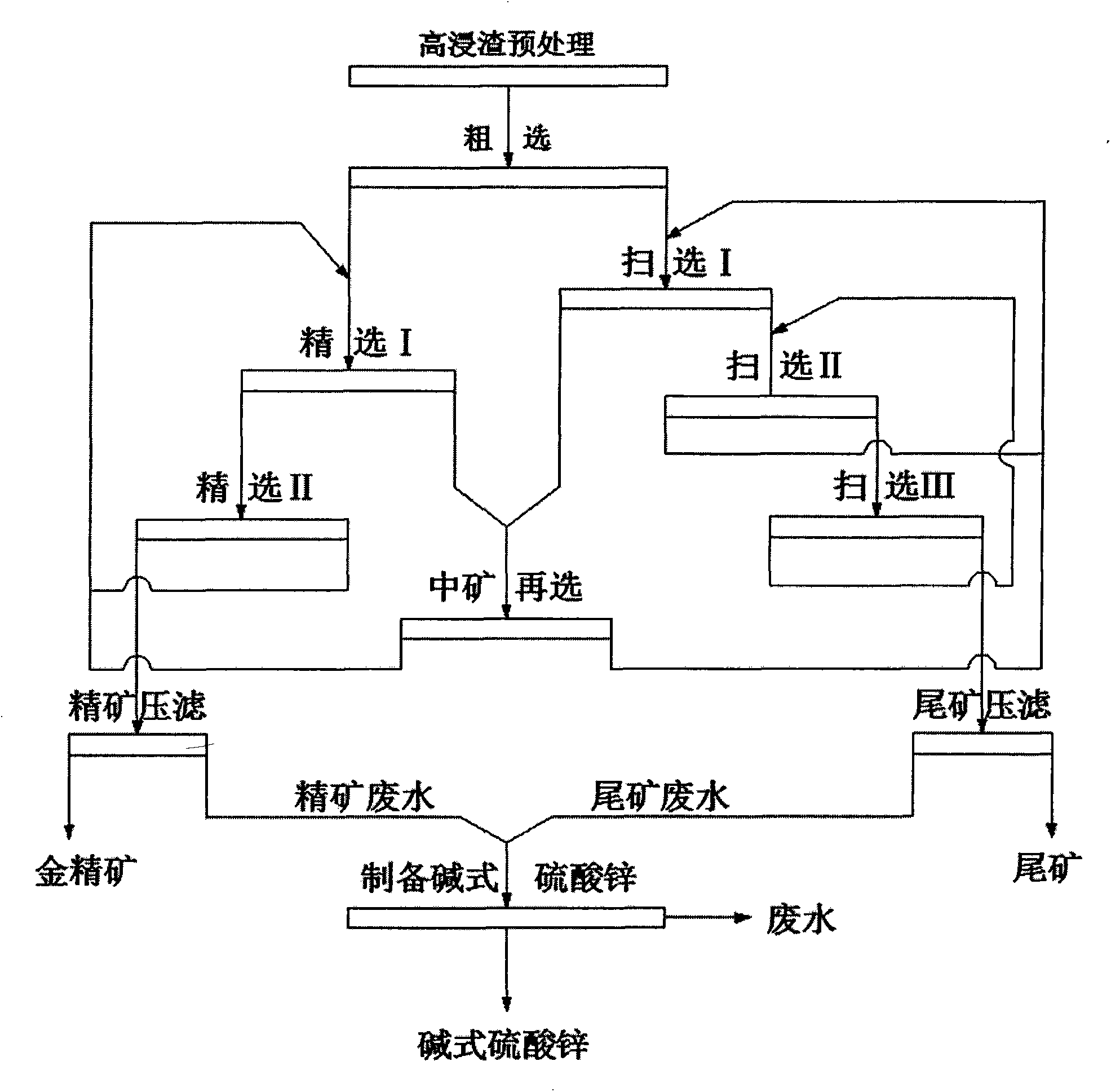

Method for comprehensively recovering gold and zinc from high leaching residue and recycling wastewater

A wastewater circulation and high leaching slag technology, which is applied in the field of mineral processing, can solve the problems of no reference materials for chemicals and measurement, and achieve the effects of environmental protection and resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of method that comprehensively reclaims gold and zinc and waste water recycling from high leaching slag, it comprises the steps:

[0034] (a) High leaching slag pretreatment: high leaching slag and water are mixed and stirred at a ratio of slurry concentration of 40% to form a high leaching slag slurry, and lime milk is added to adjust the pH to 4.3; Sodium phosphate, activated carbon, activator Na 2 S, adding 90 grams of sodium hexametaphosphate, 3000 grams of activated carbon, and activator Na 2 S is 1000 grams, after 20 minutes of reaction, the pretreated high leaching slag pulp is obtained;

[0035] (b) Rough separation: Add butylamine black medicine, Z-200 and foaming agent BK-901 to the pretreated high leaching slag pulp, add 700 grams of butylamine black medicine and 100 grams of Z-200 per ton of high leaching slag gram, foaming agent BK-901 is 20 grams; select roughing concentrate and roughing tailings;

[0036] (c) Concentration I: Add b...

Embodiment 2

[0044] Embodiment 2: a kind of method that comprehensively reclaims gold and zinc and waste water recycling from high leaching slag, it comprises the steps:

[0045] (a) High leaching slag pretreatment: high leaching slag and water are mixed and stirred at a ratio of slurry concentration of 45% to form a high leaching slag slurry, and lime milk is added to adjust the pH to 4.4; Sodium phosphate, activated carbon, activator Na 2 S, adding 80 grams of sodium hexametaphosphate, 2800 grams of activated carbon, and activator Na 2 S is 1100 grams, obtains the pretreatment high leaching slag pulp after 18 minutes of reaction;

[0046] (b) Rough separation: Add butylamine black medicine, Z-200 and foaming agent BK-901 to the pretreated high leaching slag pulp, adding 720 grams of butylamine black medicine and 110 grams of Z-200 per ton of high leaching slag gram, foaming agent BK-901 is 22 grams; select roughing concentrate and roughing tailings;

[0047] (c) Concentration I: Add b...

Embodiment 3

[0054] Embodiment 3: a kind of method that comprehensively reclaims gold and zinc and waste water recycling from high leaching slag, it comprises the steps:

[0055] (a) High leaching slag pretreatment: high leaching slag and water are mixed and stirred at a ratio of slurry concentration of 35% to form a high leaching slag slurry, and lime milk is added to adjust the pH to 4.2; Sodium phosphate, activated carbon, activator Na 2 S, adding 100 grams of sodium hexametaphosphate, 3300 grams of activated carbon, and activator Na 2 S is 900 grams, and after 28 minutes of reaction, the pretreated high leaching slag pulp is obtained;

[0056] (b) Rough separation: Add butylamine black medicine, Z-200 and foaming agent BK-901 to the pretreated high leaching slag slurry, add 680 grams of butylamine black medicine and 95 grams of Z-200 per ton of high leaching slag gram, foaming agent BK-901 is 18 grams; select roughing concentrate and roughing tailings;

[0057] (c) Concentration I: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com