Vacuum thermal bonding device and vacuum thermal bonding method

A vacuum heating and bonding device technology, applied in lamination devices, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve problems such as poor sealing, difficult-to-seal bonding, and damaged sealing corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

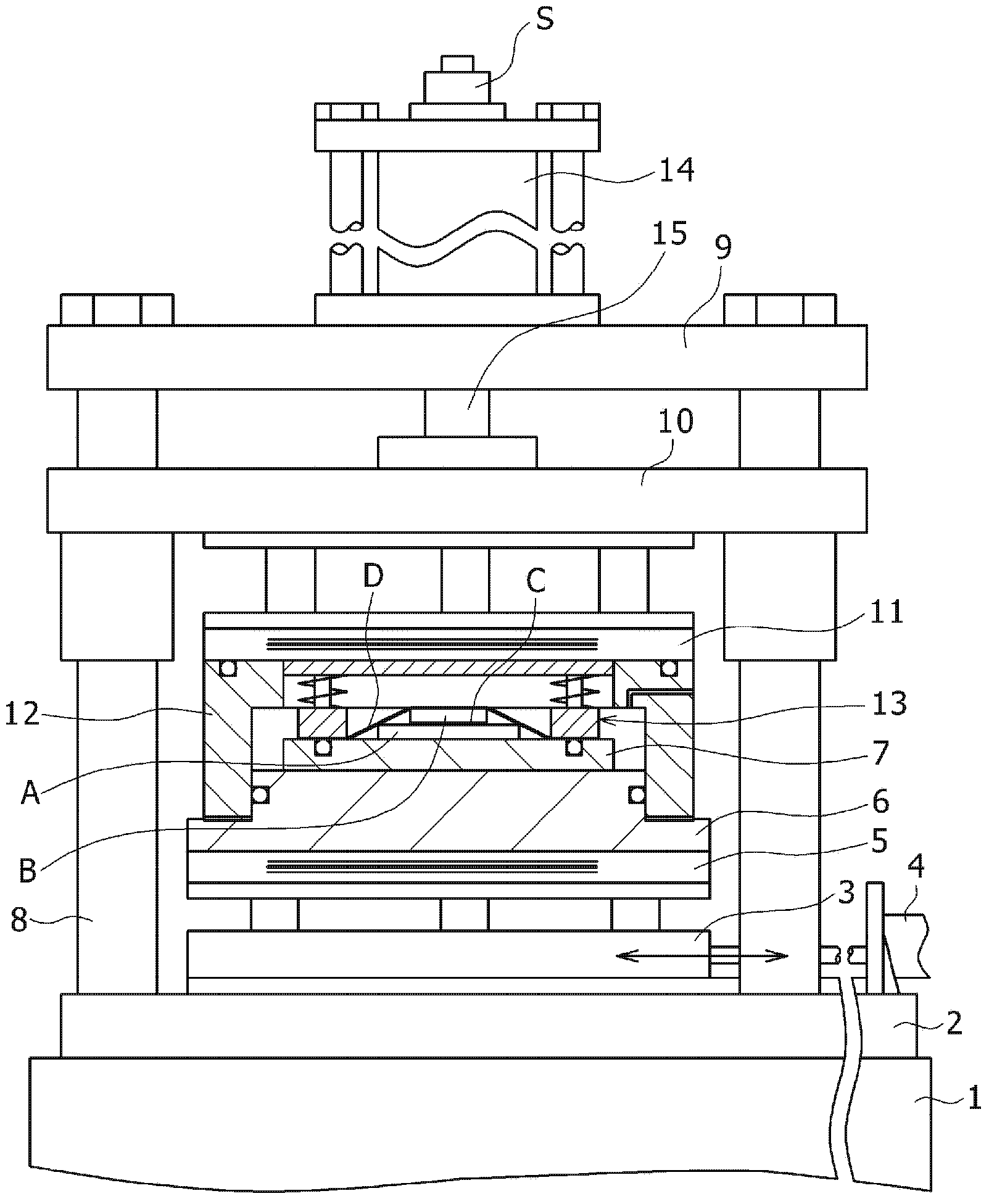

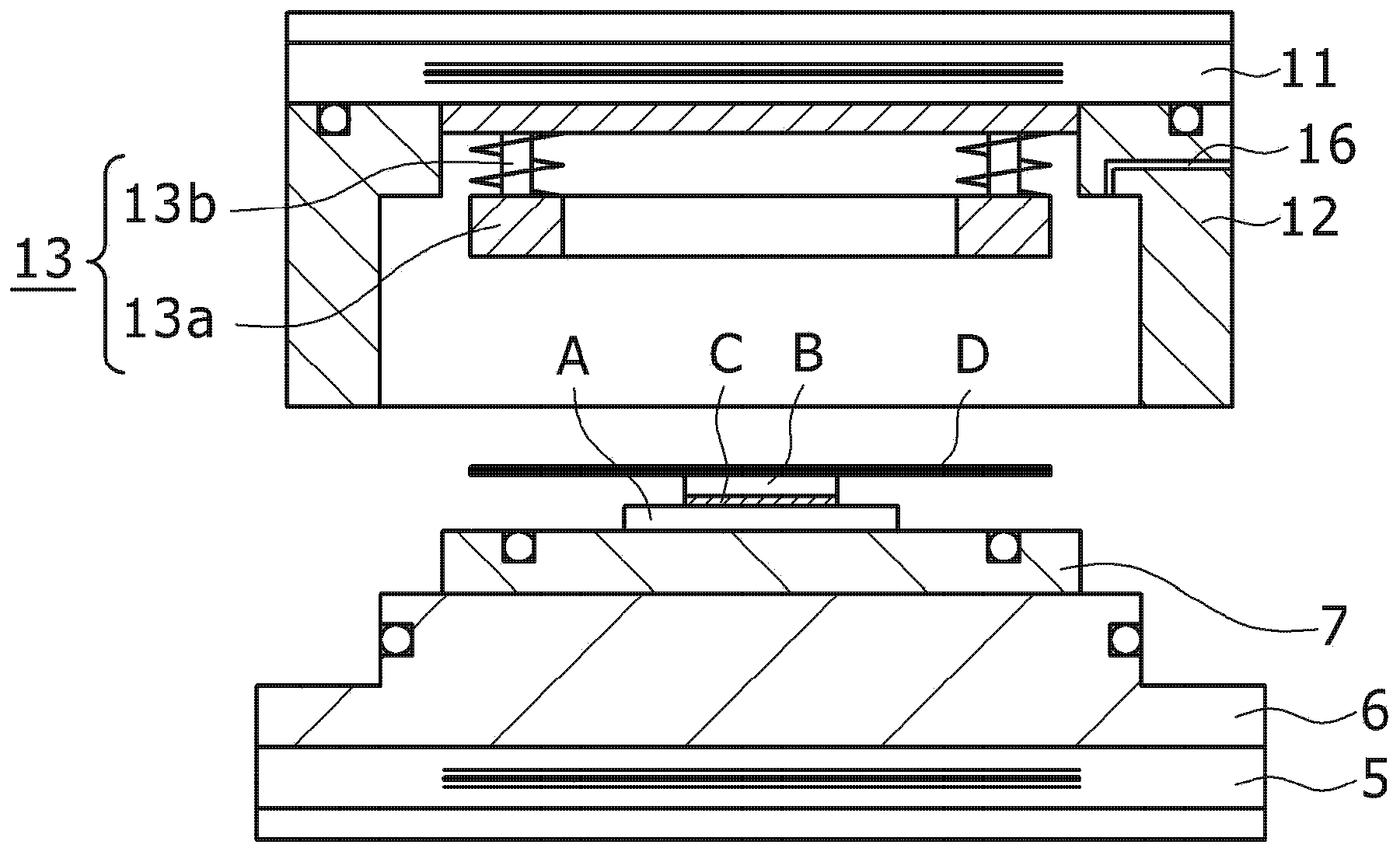

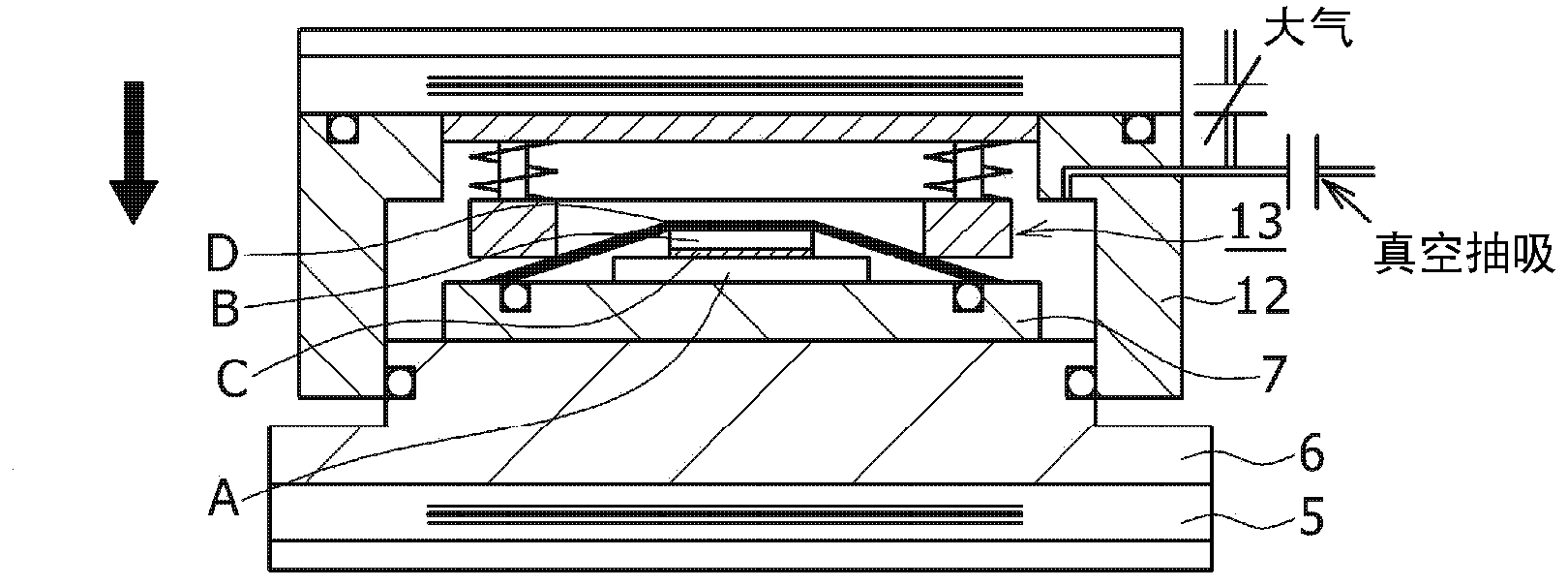

[0109] figure 1 The vacuum heating bonding apparatus of the present invention according to the first embodiment is shown in . In this vacuum heating bonding apparatus, a pressurized cylinder lower plate 2 is arranged on the base 1, and a slide movable table 3 is arranged on the pressurized cylinder lower plate 2. The heated joint moves in and out. A lower heating plate 5 is thermally insulated above the sliding table 3 , a lower plate member 6 is arranged on the upper surface of the lower heating plate 5 , and a substrate mounting table 7 is placed on the upper surface of the lower plate member.

[0110] A plurality of struts 8 are arranged vertically on the pressurizing cylinder lower plate 2 , and a pressurizing cylinder upper plate 9 is fixed to the upper ends of the struts 8 . The pillar 8 can also be directly arranged vertically on the abutment 1 . Below the upper plate 9 of the pressurizing cylinder, an intermediate moving member (intermediate member) 10 is arranged s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com