Three-level three-phase half-bridge inverter circuit

An inverter circuit and three-phase half-bridge technology, which is applied to electrical components, AC power input to DC power output, output power conversion devices, etc., can solve the problems of large switching loss, low efficiency, and low capacity. Achieve the effects of reducing switching loss, high reliability, and easy expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

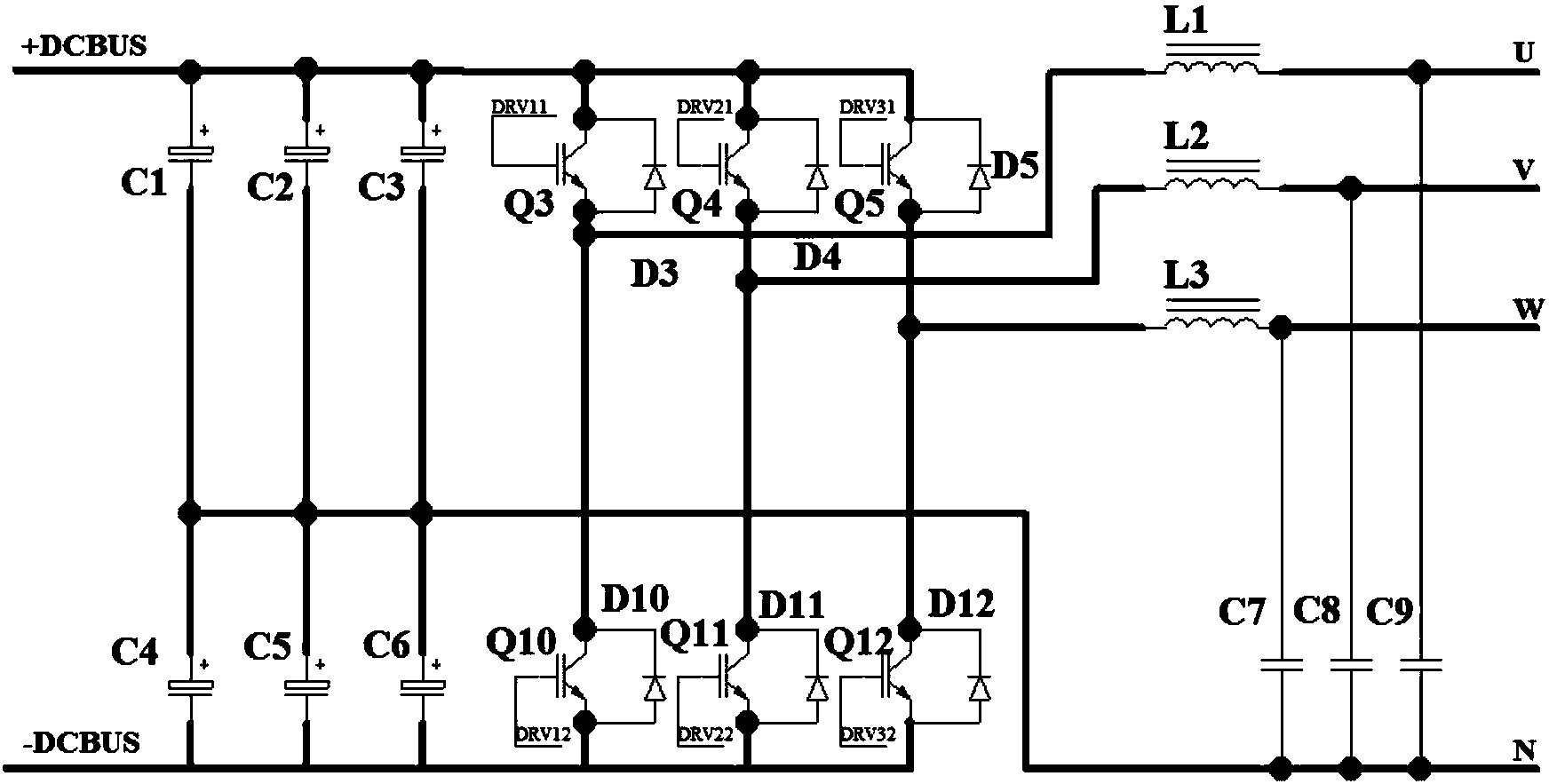

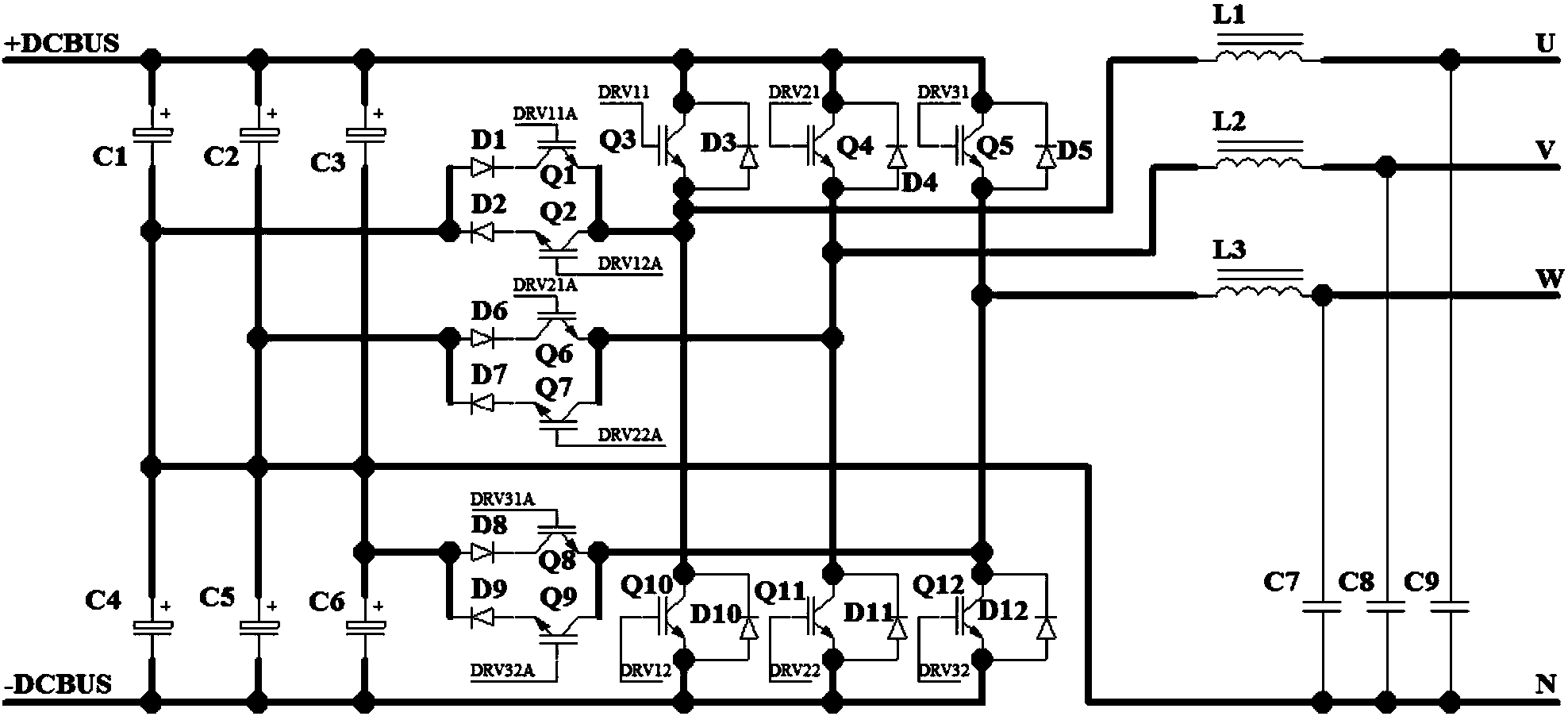

[0017] as attached figure 2 As shown, the present invention provides a three-level three-phase half-bridge inverter circuit, which can be split into three independent single-phase half-bridge circuits A, B, and C.

[0018] Single-phase half-bridge circuit A includes ionized electrolyte capacitors C1, C4, capacitor C9, diodes D1, D2, D3, D10, high-power switching tubes Q1, Q2, Q3, Q10, and inductor L1;

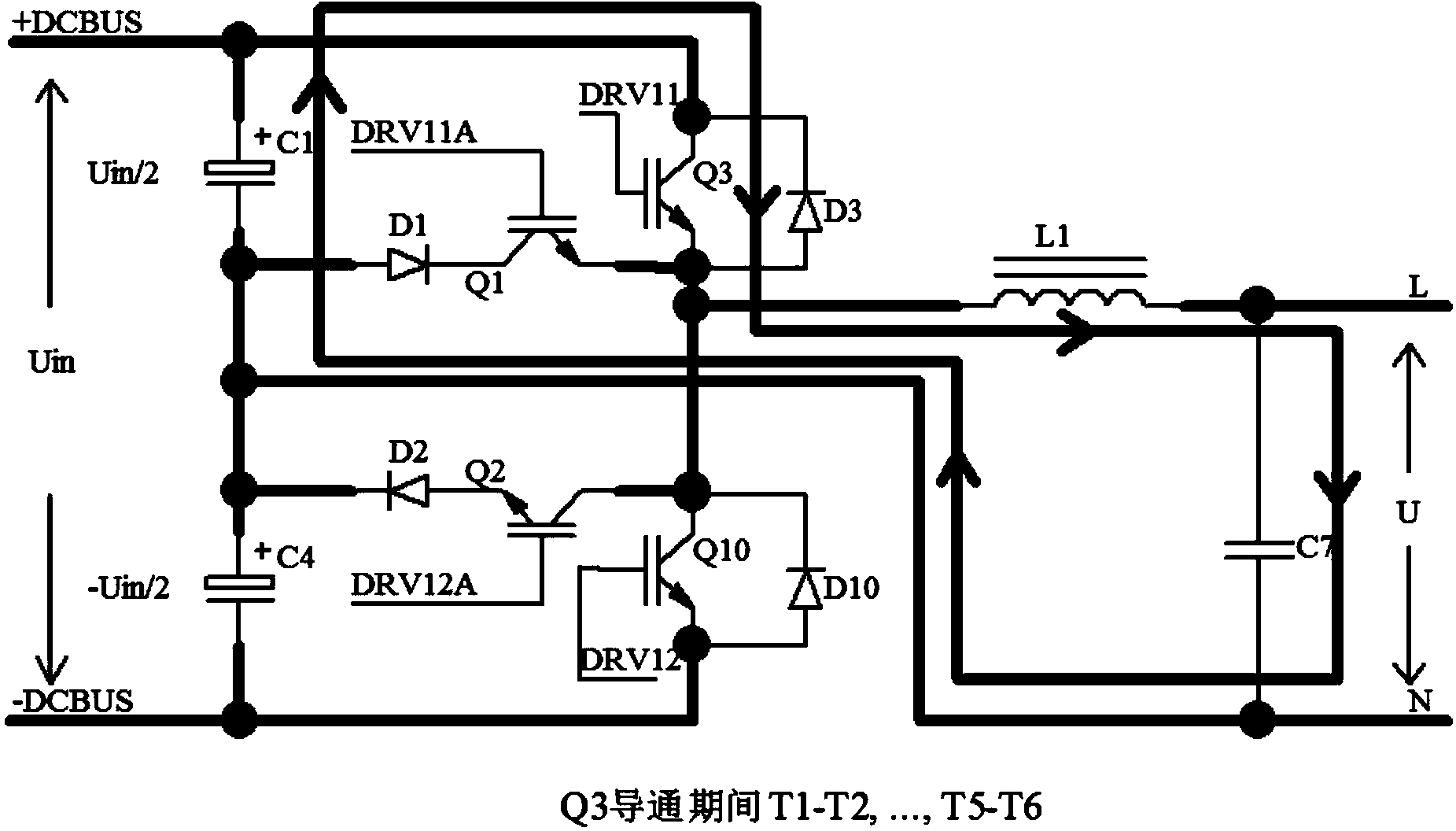

[0019] The positive pole of the ionizing electrolyte capacitor C1 is connected to the DC input +DCBUS, the negative pole of the ionizing electrolyte capacitor C1 is connected to the positive pole of the ionizing electrolyte capacitor C4, the negative pole of the ionizing electrolyte capacitor C4 is connected to the DC input-DCBUS, and the positive pole of the diode D1 is connected to the ionizing electrolyte capacitor C1 and the ionization Between the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com