Trivalent vanadium ion electrolyte and preparation method thereof, and vanadium battery

A trivalent vanadium and electrolyte technology, which is applied in the field of vanadium batteries, can solve the problem of low purity of vanadium ion electrolyte and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

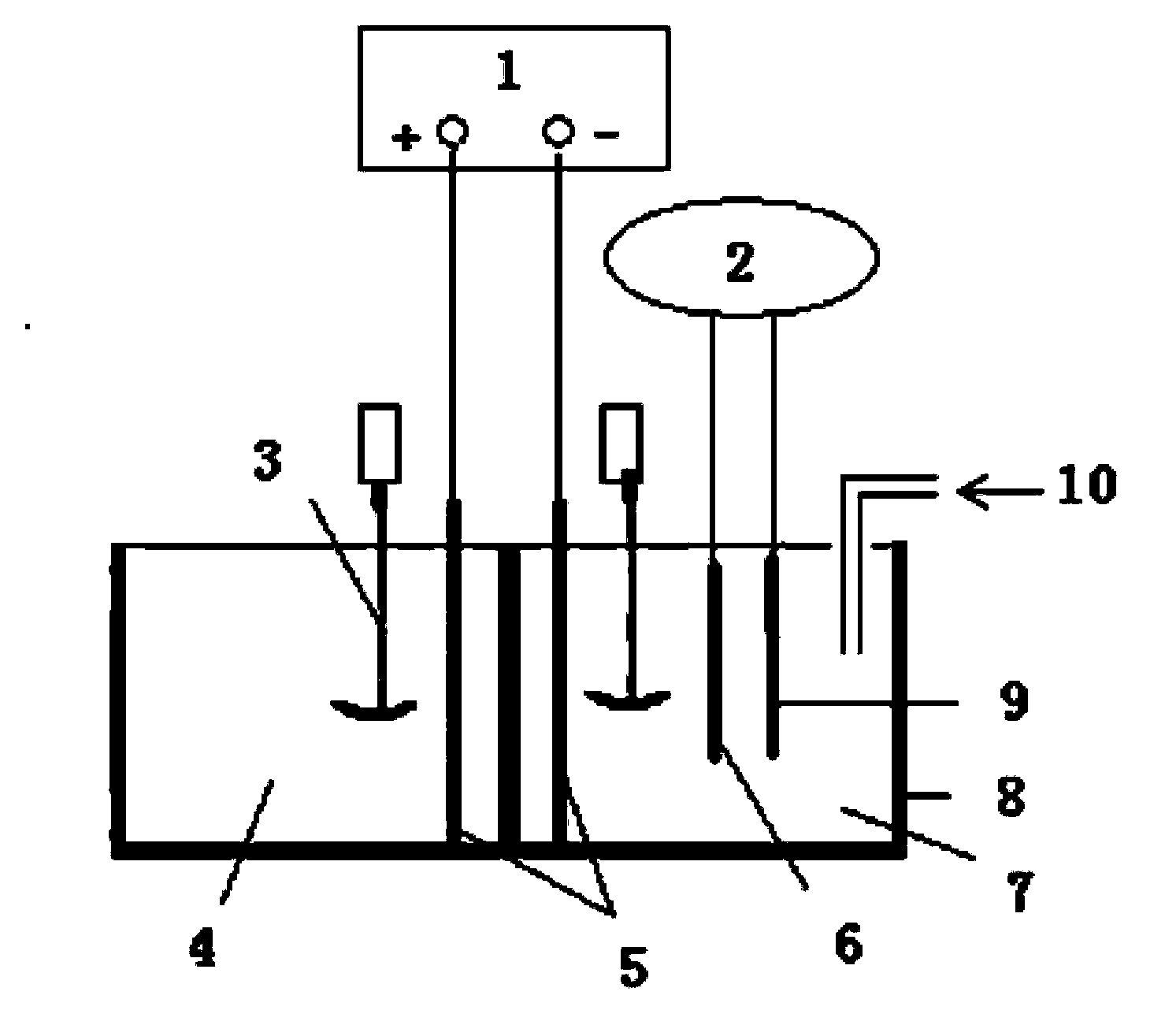

Image

Examples

preparation example 1

[0050] This preparation example is used to illustrate the trivalent vanadium ion electrolyte provided by the present invention and its preparation method.

[0051] Production of the electrolytic cell: use polyethylene with a weight average molecular weight of 3.5 million to make an anode pool and a cathode pool with specifications of 170×170×170mm, and place a perfluorosulfonic acid ion exchange membrane between the anode pool and the cathode pool and fix them , and then place the two platinum plates connected to the positive and negative poles of the external constant voltage power supply in the anode pool and the cathode pool respectively, wherein the effective area of the platinum plate is 100×100mm 2 .

[0052] Preparation of sulfuric acid solution containing vanadyl sulfate: first add 550mL deionized water to the reactor, then add 259mL concentrated sulfuric acid to the reactor under stirring conditions, and when the temperature rises to 80°C, add 62 grams of V 2 o 3 ...

preparation example 2

[0062] This preparation example is used to illustrate the trivalent vanadium ion electrolyte provided by the present invention and its preparation method.

[0063] Production of the electrolytic cell: use polyethylene with a weight average molecular weight of 4 million to make an anode pool and a cathode pool with specifications of 170×170×170mm, and place a perfluorosulfonic acid ion exchange membrane between the anode pool and the cathode pool and fix it , and then place the two platinum plates connected to the positive and negative poles of the external constant voltage power supply in the anode pool and the cathode pool respectively, wherein the effective area of the platinum plate is 100×100mm 2 .

[0064] Preparation of sulfuric acid solution containing vanadyl sulfate: first add 600mL deionized water to the reactor, then add 288mL concentrated sulfuric acid to the reactor under stirring conditions, and when the temperature rises to 80°C, add 75 grams of V 2 o 3 with...

preparation example 3

[0068] This preparation example is used to illustrate the trivalent vanadium ion electrolyte provided by the present invention and its preparation method.

[0069] Production of the electrolytic cell: use polyethylene with a weight average molecular weight of 4 million to make an anode pool and a cathode pool with specifications of 170×170×170mm, and place a perfluorosulfonic acid ion exchange membrane between the anode pool and the cathode pool and fix it , and then place the two platinum plates connected to the positive and negative poles of the external constant voltage power supply in the anode pool and the cathode pool respectively, wherein the effective area of the platinum plate is 100×100mm 2 .

[0070] Preparation of sulfuric acid solution containing vanadyl sulfate: first add 600mL deionized water to the reactor, then add 269mL concentrated sulfuric acid to the reactor under stirring conditions, and when the temperature rises to 80°C, add 61.7 grams of V 2 o 3 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com