Method of improving laser processing efficiency by optimizing light beam quality

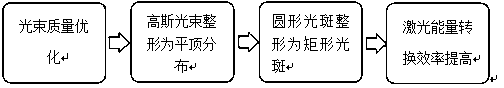

A technology of laser beam quality and laser spot, applied in the field of optimizing beam quality and improving laser processing efficiency, can solve the problems of poor laser beam quality, destroying the characteristics of the material itself, uneven laser beam energy distribution, etc., achieving quality optimization and simple process method , the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

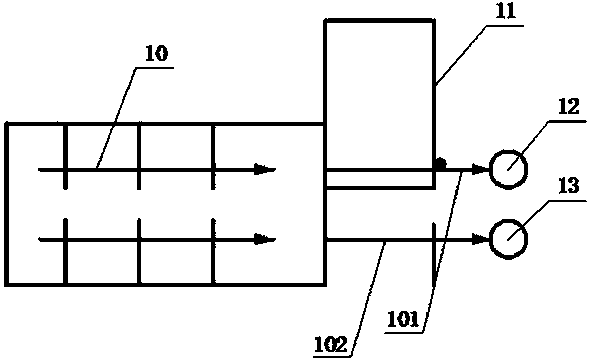

[0021] Now combined with the accompanying drawings, the power density emitted by the Nd:YAG laser is 1.54GW / cm 2 , a laser with a wavelength of 1.06 μm and a spot diameter of 6 mm is taken as an example to describe the technical solution of the present invention in more detail.

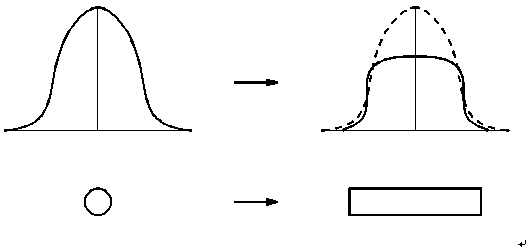

[0022] First, through the shaping system of the Galileo-type aspheric mirror group, it is optimally shaped from a Gaussian beam to a super-Gaussian flat-top distribution. The shaping process is as follows figure 1 shown. The shaping system of the Galileo-type aspheric mirror group includes a Galileo-type aspheric mirror group, and the Galileo-type aspheric mirror group is composed of a plano-concave aspheric mirror 4 and a plano-convex aspheric mirror 5, and the incident light beam passes through the plano-concave aspheric mirror 4. After modulation, a light beam with uniform intensity distribution is obtained, and the function of the plano-convex aspheric mirror 5 is to ensure that the uniform ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com