Single-edge fastening bolt

A technology for unilaterally tightening bolts and bolts, used in threaded fasteners, deformable fasteners, screws, etc., can solve the problems of many parts and slow installation speed, to ensure integrity, easy and fast installation, avoid The effect of opening weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

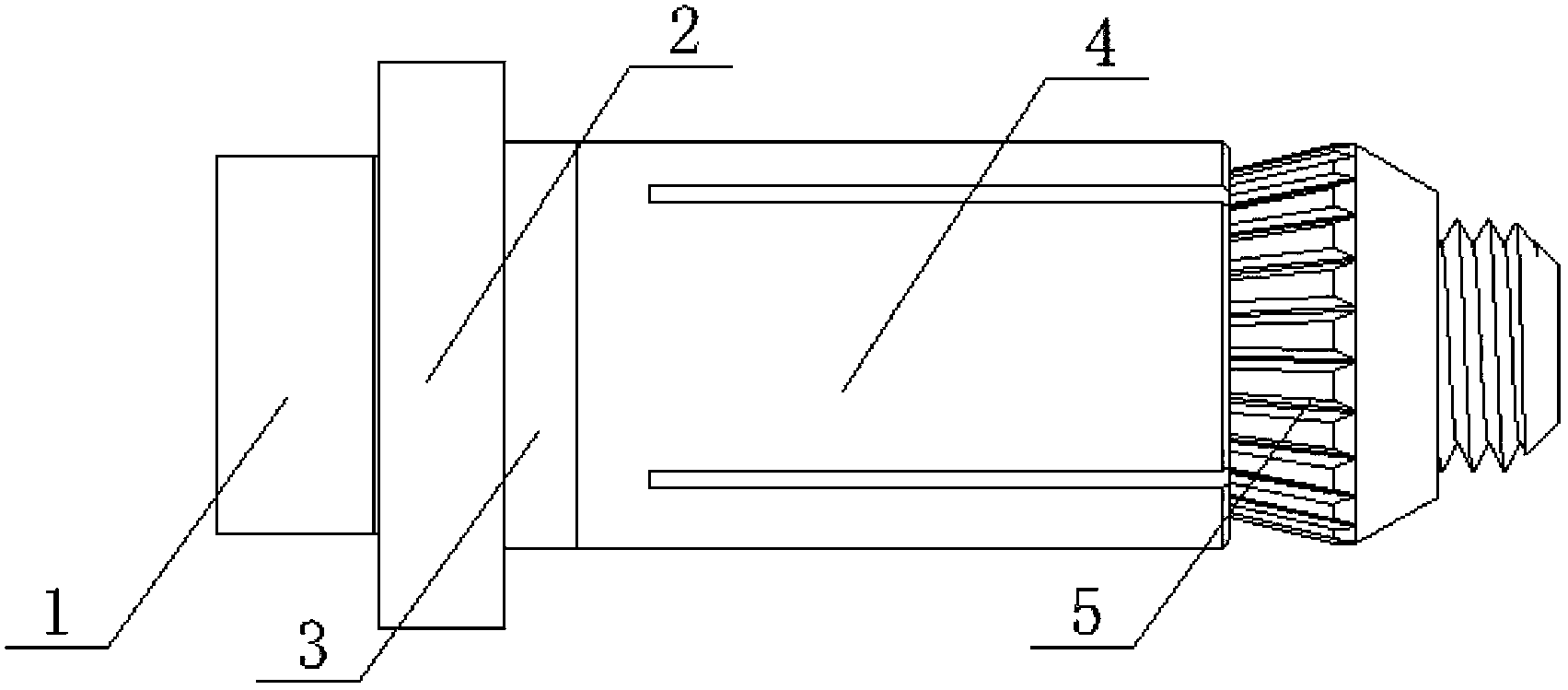

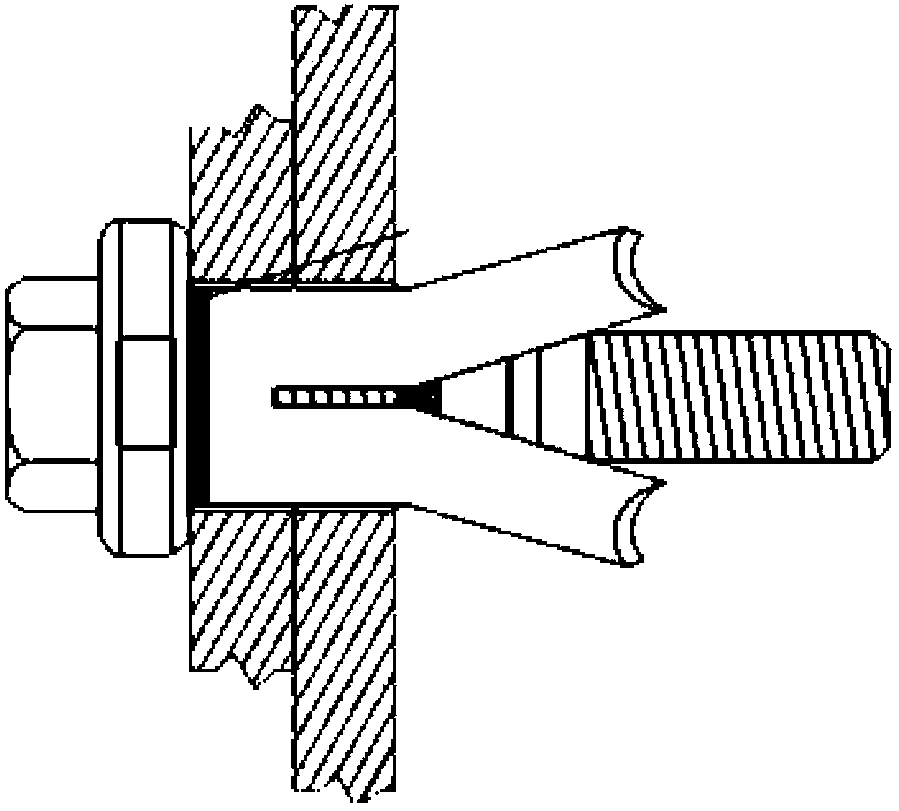

[0034] figure 1 Shown is an embodiment of the unilateral fastening bolt of the present invention. In order to solve the one-way assembly problem, the technical solution adopted in the present invention is: a conventional bolt includes a screw rod and a bolt head 1 at one end of the screw rod, and the present invention starts from the bolt head 1 on the screw rod. The head end is provided with a washer 2, a casing 4 and a cone head 5 in sequence, and a screw hole is provided on the cone head to be threadedly connected with the screw rod ( Figure 8 and Figure 9 As shown), the spacer 2, sleeve 4 and the screw are clearance fit, the outer diameter of the sleeve is larger than the inner diameter of the washer, and there are multiple axial slits on the end of the sleeve near the cone head, and the small end of the cone head snaps into the sleeve , the outer diameter of the big end of the cone head is greater than or equal to the inner diameter of the casing. Such as figure 2 A...

Embodiment 2

[0038] In Embodiment 1, the casing 4 is a cylindrical casing, and the casing can also be trumpet-shaped, square or other shapes, and the ultimate goal is to ensure that the casing 4 can be stretched by the cone head 5 . When the sleeve is trumpet-shaped, its small opening end faces the gasket 2, and its large opening end faces the cone head 5, and the outer diameter of the large end of the cone head should be greater than or equal to the maximum outer diameter of the sleeve, and the inner diameter of the gasket should be smaller than that of the sleeve. The minimum outside diameter of the tube. Compared with other shapes, it is obvious that the force of the cylindrical sleeve is more uniform when it is stretched by the cone head, and it is easier to be stretched, and the cylindrical sleeve is also more suitable for the cylindrical screw.

[0039] Because the casing 4 is gradually stretched from the cone end, the wall thickness of the casing gradually becomes thinner from the w...

Embodiment 3

[0041] In order to facilitate the locking of the casing 4 and the cone head 5 so that it cannot be rotated relative to each other, the outer surface of the cone head is set to be uneven. Theoretically, as long as enough pressure is applied to achieve a high enough friction between the sleeve and the cone, the cone with a smooth outer surface can also achieve the purpose of locking the sleeve, but obviously the friction provided by the uneven surface of the cone Higher force for better fixation. And preferably, as figure 1 As shown, in this embodiment, the outer surface of the cone head is evenly distributed with multiple rows of convex ribs, which not only increases the friction force, but also the convex ribs are easy to snap into the cracks on the casing to lock the casing.

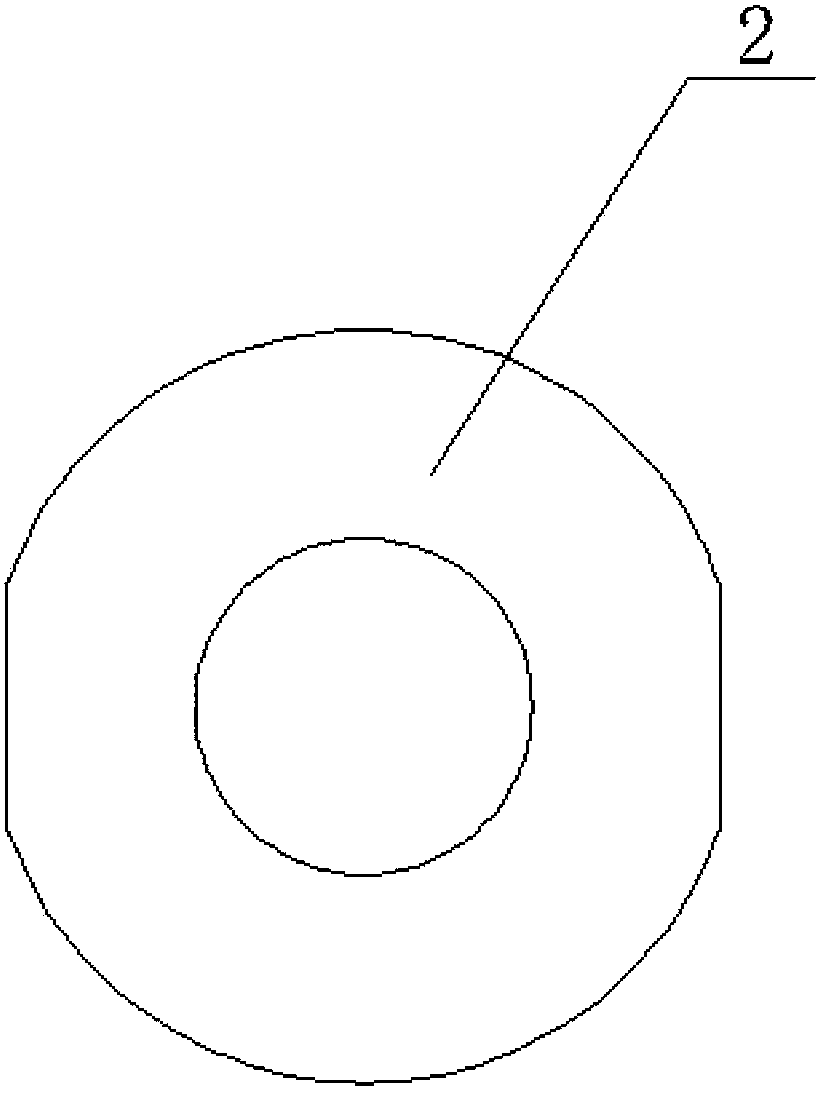

[0042] Such as image 3 and Figure 4 As shown, the outer peripheral surface of the washer is provided with two symmetrical planes, which facilitates the use of tools to hold the washer.

[0043] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com