Gas engine load adaptive gas device

A gas engine and gas device technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as poor energy saving effect and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

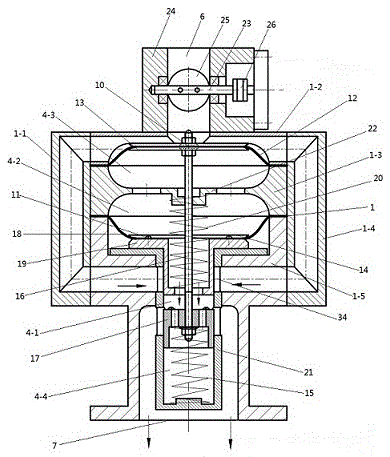

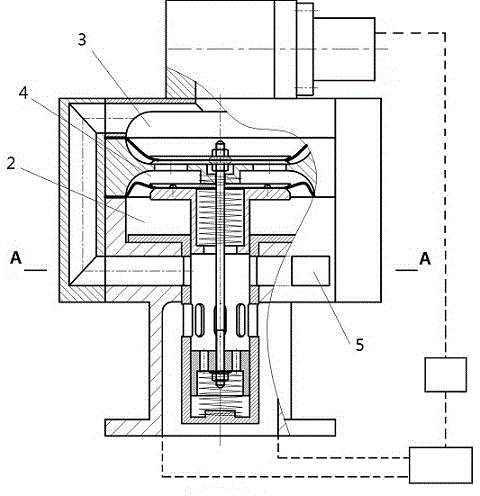

[0031] Such as figure 1 , 2 , 3: a gas engine load self-adaptive gas device, including a casing 1 with an accommodating cavity

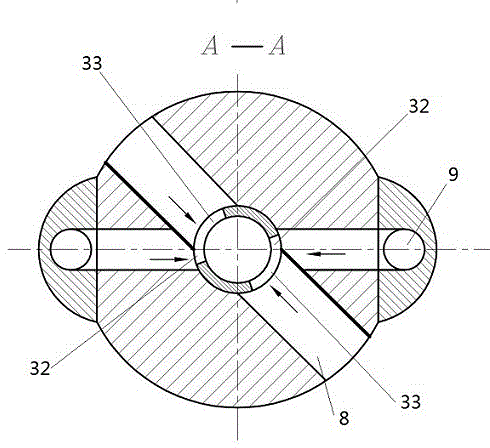

[0032](combined and fixed by five parts 1-1, 1-2, 1-3, 1-4, 1-5) and the air chamber 2, gas chamber 3 and gas mixing chamber arranged in the cavity Chamber 4, air inlet 5, gas inlet 6 and mixed gas outlet 7 are arranged on the shell, air channel 8 and gas channel 9 are formed between the inner surface of the shell and the walls of air chamber 2 and gas chamber 3 respectively, and also includes The upper diaphragm assembly 10, the lower diaphragm assembly 11, the upper diaphragm assembly 10 separates the gas chamber 3 and the gas mixing chamber 4, the lower diaphragm assembly 11 separates the air chamber 2 and the gas mixing chamber 4, and the gas mixing chamber There is a perforated partition 22 extending from the shell between the upper and lower diaphragms;

[0033] The upper diaphragm assembly 10 includes an upper diaphragm 12 , two symmetrical...

Embodiment 2

[0046] Such as figure 2 , 3 Shown in , 4: different from embodiment 1: also comprise electronic speed control controller 29, the signal input end of electronic speed control controller 29 connects the speed sensor 30 on the engine 28, and the control output end connects throttle valve 25 places The executive motor 27 and the electronic speed control controller 29 compare the rotational speed parameters collected by the speed measuring sensor 30 with the internally set rotational speed parameters, and intelligently adjust the intake of gas according to the comparison results. For example: when the rotational speed of the engine 28 is lower than the set value (after parameter comparison), the electronic speed control controller 29 outputs the "increase" drive pulse to the actuator motor 27, and the actuator motor 27 rotates the throttle to "increase" the throttle. The direction of the opening of the valve 25 is rotated to ensure that the increased gas enters the gas chamber 3,...

Embodiment 3

[0048] Such as Figure 5 As shown: the difference from Embodiment 1 and 2 is that the piston sleeve 21 is provided with a rotating rod 31 that can be rotated, and pushing the rotating rod 31 can change the ratio of the cross-sectional area of the air and gas passing through the air inlet hole on the piston sleeve 21, Then it can adjust the intake volume of air and gas, and adjust the mixing ratio of air and gas in rough steps.

[0049] The diaphragms described in the above three embodiments are made of elastic soft materials, so that they are more sensitive when sensing pressure changes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com