Active regeneration control method and device for particulate trap

A particulate filter, active regeneration technology, applied in the field of machinery, can solve the problems of DPF pressure difference measurement change, influence the starting time determination, inaccurate carbon load, etc., to ensure accurate control, reduce fuel consumption, carbon load and other problems. accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

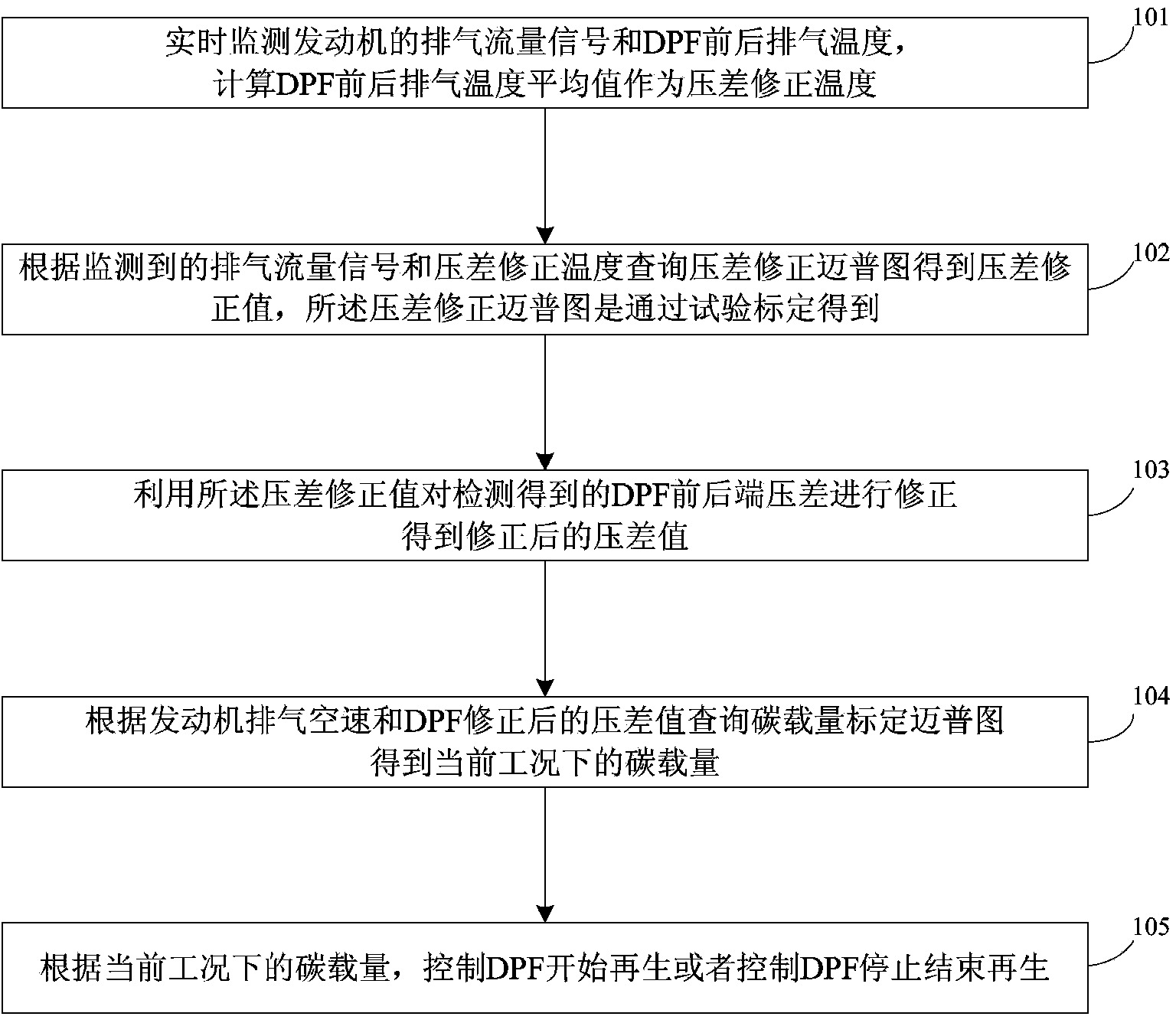

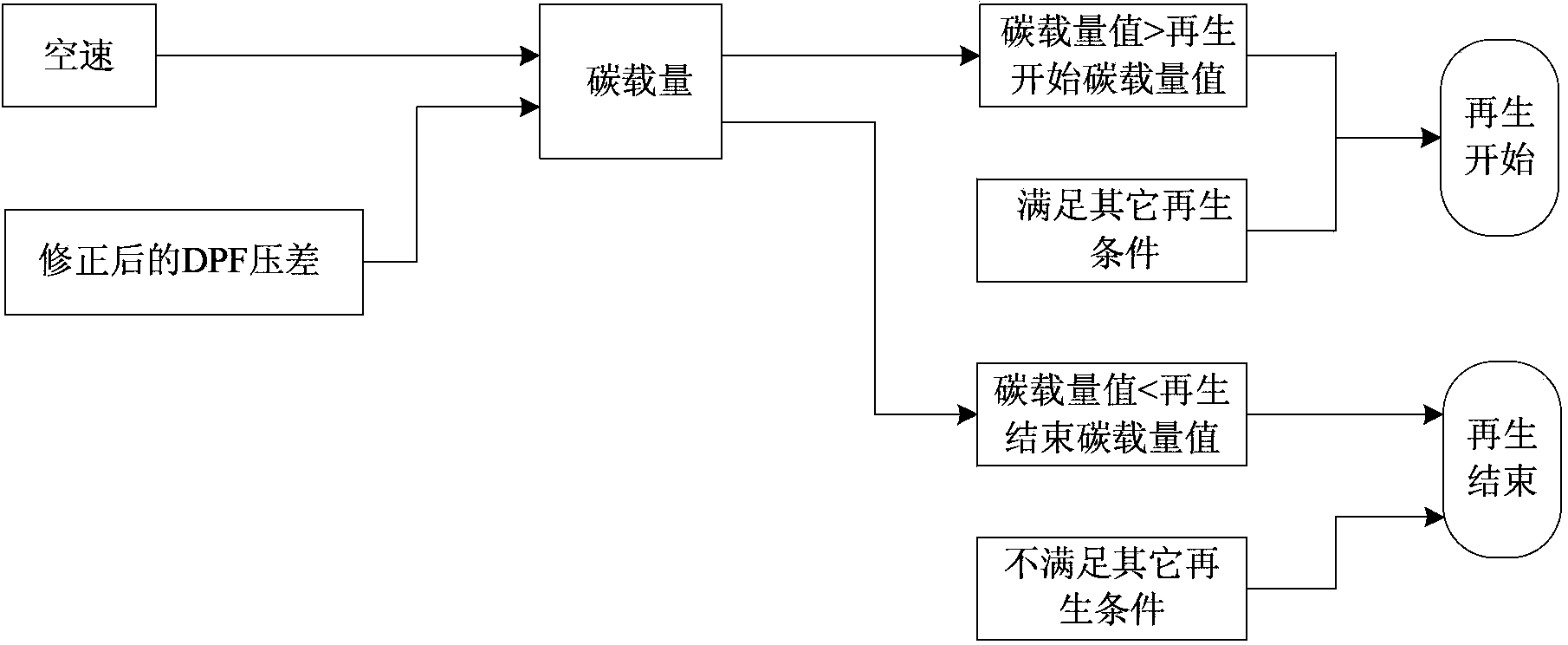

[0044] see figure 1 , which is a method flow chart of an active regeneration control method for a particulate matter trap disclosed in Embodiment 1 of the present invention, specifically including the following steps:

[0045] Step 101: Monitor the exhaust flow signal of the engine and the exhaust gas temperature before and after the DPF in real time, and calculate the average value of the exhaust temperature before and after the DPF as the differential pressure correction temperature;

[0046] Generally, when there are temperature sensors at the front and back of the DPF, the front and rear temperatures can be measured; if there is no temperature sensor at the rear end of some DPFs, preferably, when only the exhaust temperature at the front end of the DPF is monitored, the exhaust temperature at the front end of the DPF is used as the pressure difference Correct the temperature.

[0047] Step 102: According to the monitored exhaust flow signal and differential pressure corre...

Embodiment 2

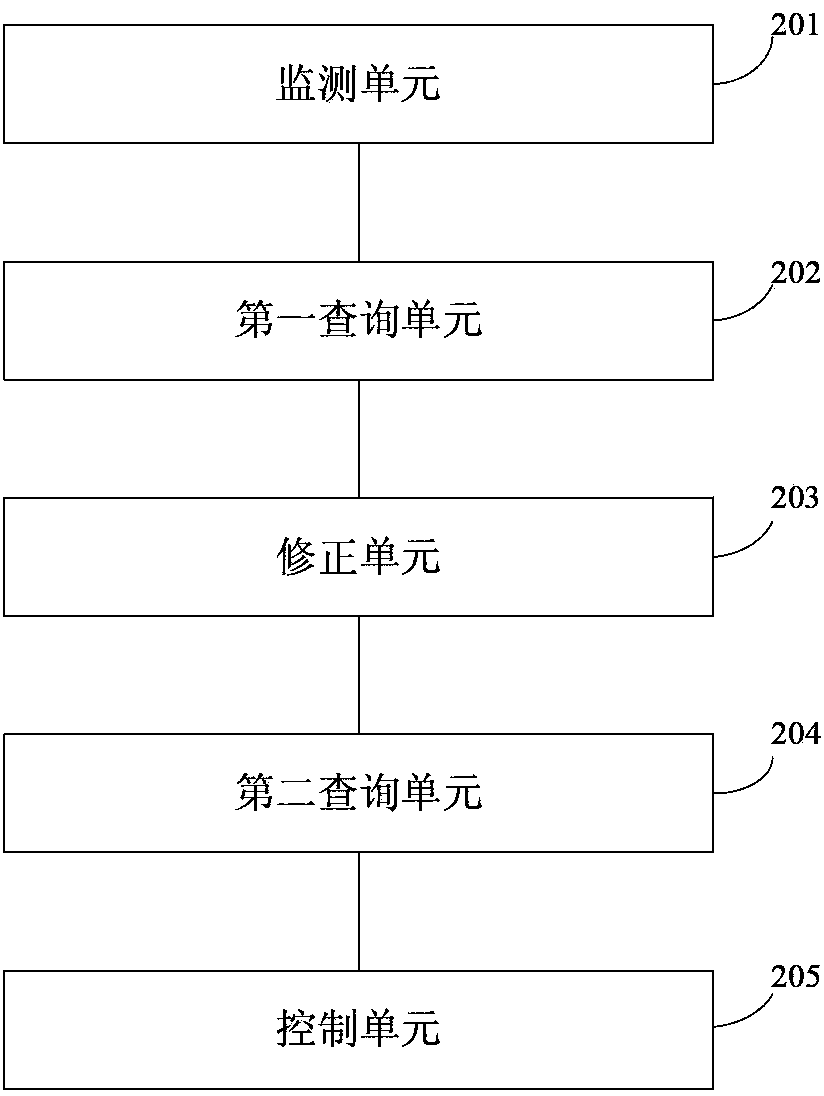

[0060] The present invention also provides an active regeneration control device for particulate matter traps, please refer to figure 2 , which is a schematic structural diagram of an active regeneration control device for a particulate matter trap disclosed in Embodiment 2 of the present invention. The device specifically includes: a monitoring unit 201, a first query unit 202, a correction unit 203, a second query unit 204 and control unit 205 .

[0061] The monitoring unit 201 is used to monitor the exhaust flow signal of the engine and the exhaust gas temperature before and after the DPF, and calculate the average value of the exhaust gas temperature before and after the DPF as the differential pressure correction temperature;

[0062] The first query unit 202 is used to query the differential pressure correction map according to the monitored exhaust gas flow signal and differential pressure correction temperature to obtain a differential pressure correction value, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com