Dry ice explosion and air-permeability-enhancing device and method for drawing out gas by using same

A detonating device and dry ice technology, applied in gas discharge, safety devices, earthwork drilling and mining, etc., can solve problems such as threats to coal mine safety production, prone to "dummy guns", and lower system reliability, to achieve safe and effective gas drainage methods, Avoiding difficulties in explosive delivery and enhancing the effect of gas drainage methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

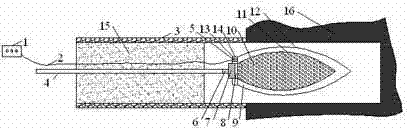

[0019] Example 1, such as figure 1 As shown, a dry ice explosion anti-reflection device includes an initiating device, an adiabatic storage device, and a hole sealing device. The initiating device is composed of an initiator 1 arranged outside the borehole 3, a conductor 2 arranged in the borehole 3, and a conductor 2. The connected detonator 5 is composed of a dry ice storage chamber 10 arranged in the coal body 16, an inner shell 11 outside the dry ice storage chamber 10, a first vacuum chamber 9 outside the inner shell 11, and a first vacuum chamber 9 outside the The housing 12, the sealed male thread 7 connecting the dry ice storage chamber 10 and the delivery rod 4, the sealed female thread 14 connected with the sealed male thread 7, and the detonator cavity 13 connected with the sealed female thread 14, the hole sealing device is set in the drill Polyurethane 15 in the hole, the sealed male thread 7 is composed of a second vacuum chamber 8 and a quick connector 6. The sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com