Solid-free drilling fluid

A drilling fluid and solid phase-free technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problem of unavailability of fluid loss control agent in solid phase-free drilling fluid system, and achieve good use effect and application value. , stable performance, good lubricity and fluid loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

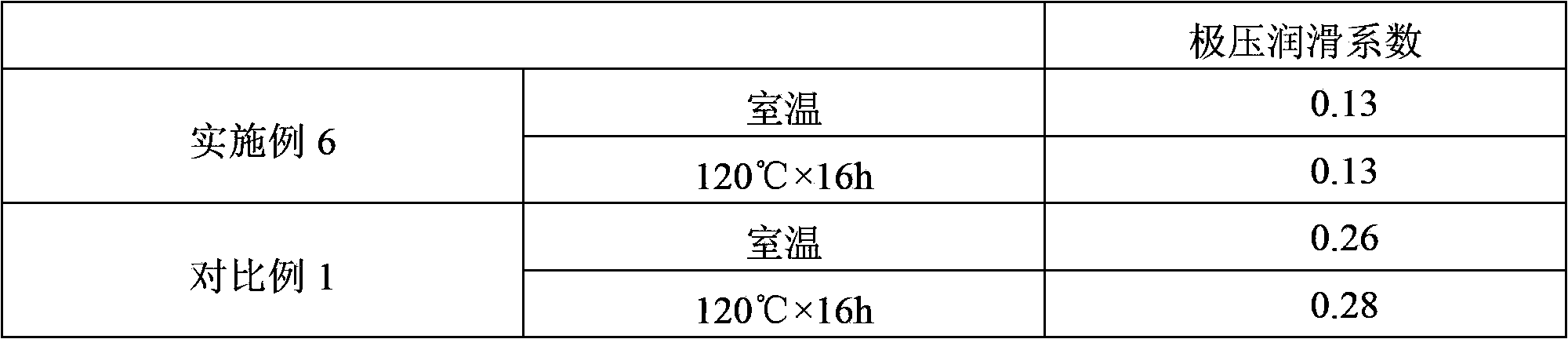

Examples

Embodiment 1

[0025] In this example, the solid-free drilling fluid is prepared with polymer swelling microparticles A. The specific steps are: add 400mL of water and 1g (0.25wt%) polymer swelling particle A to the high stirring cup; and stir the solution at a high speed of 10000 rpm for 20min; check the conventional performance data at room temperature in Table 1 ; Then roll the above solution at 120°C for 16 hours, and see Table 1 for the conventional performance data after aging at 120°C.

Embodiment 2

[0027] In this example, the solid-free drilling fluid is prepared with polymer swelling microparticles A. The specific steps are: add 400mL water, 1g (0.25wt%) polymer swelling particle A and 8g (2wt%) NaCl to the high stirring cup; and stir the solution at a high speed of 10000 rpm for 20min; See Table 1 for the conventional performance data; then heat the above solution at 120°C for 16 hours, and check the routine performance data after aging at 120°C in Table 1.

Embodiment 3

[0029] In this example, the solid-free drilling fluid is prepared with polymer swelling microparticles A. The specific steps are: add 400mL water to the high stirring cup; add 2g (0.5wt%) polymer swelling particle A and 0.4g NaOH; and stir the solution at a high speed of 10000 rpm for 20min; detect its normal temperature at room temperature The performance data is shown in Table 1; and then the above solution is hot rolled at 120°C for 16 hours, and the conventional performance data after aging at 120°C is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com