A uniform cooling medium with particularly stable cooling properties

A cooling medium and stable technology, applied in the field of cooling medium used in metal thermal processing, forging, casting, heat treatment, can solve the problems of uneven cooling and insufficient cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] According to the above formula, the physical and chemical properties of the uniform cooling medium are shown in the following table:

[0023] Table 1 Physical and chemical indicators of uniform cooling medium

[0024]

[0025]

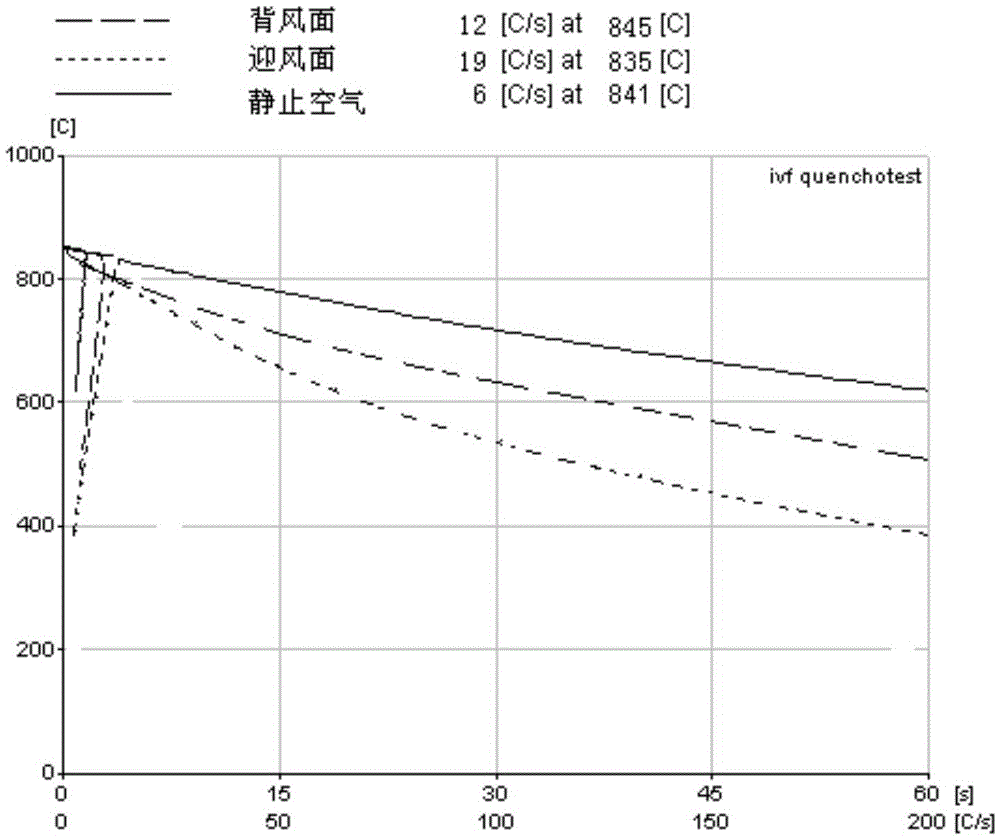

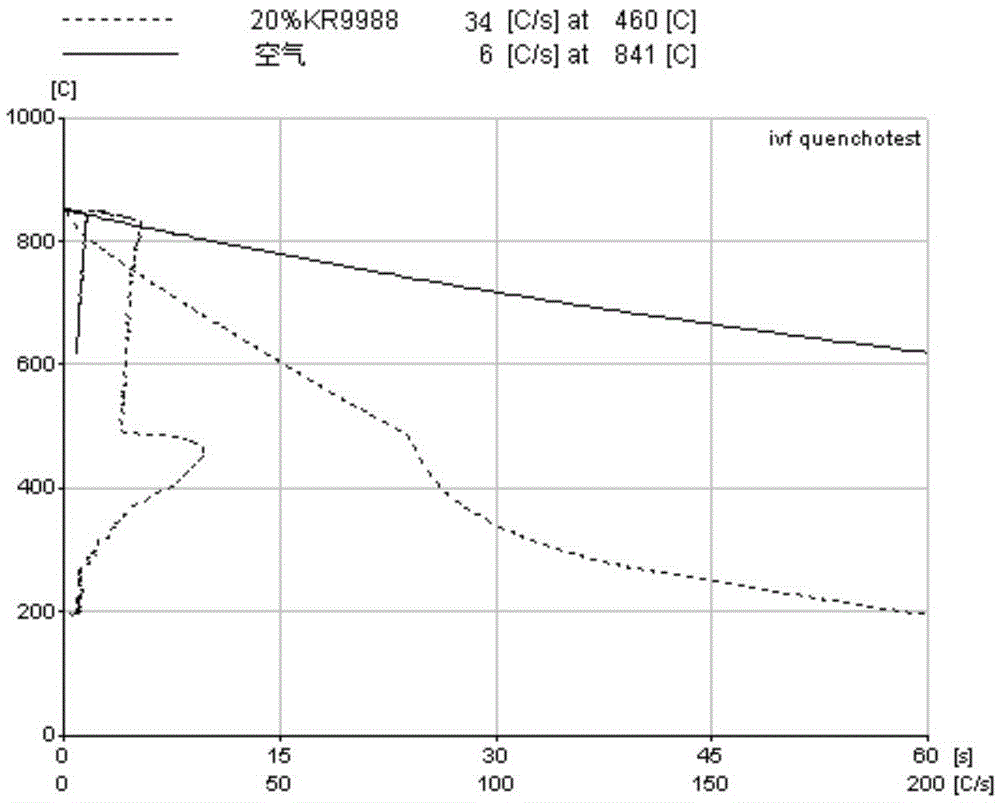

[0026] The test of the cooling characteristic of this patent adopts the international standard ISO9955, and the instrument uses the Swedish IVF cooling characteristic tester. image 3 , Figure 4 And Table 2 shows that the cooling capacity of 20% uniform cooling medium is between air and quenching oil, and above 500°C can meet the requirements of uniform cooling; Figure 5 It can be seen that the cooling characteristics of 20%-30% concentration are basically the same, and the cooling characteristics are not sensitive to the change of concentration, which can ensure the stability of cooling; Figure 6 It shows that the cooling performance of different liquid temperatures remains stable, especially above 500 °C, there is no obvious change....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com