Anti-deformation processing method and special tool for magnetic isolation groove of pull plate of transformer clamp

A technology of transformer clamps and special tools, which is applied in the field of transformers, can solve the problems of out-of-tolerance magnetic isolation slot width, rework, and easy deformation, etc., and achieve the effect of improving processing efficiency and reducing unqualified problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

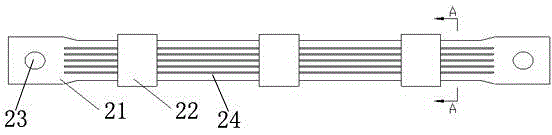

[0025] In this embodiment, the number of magnetic isolation grooves on the clamp pull plate is five, and the grooves on the special tool for anti-deformation processing are also five, and the magnetic isolation grooves are cut underwater on the clamp pull plate with a plasma cutting machine. The five magnetic isolation slots are processed in the order of 1-5; sequence 1, the middle magnetic isolation slot is processed first; sequence 2, the bottom magnetic isolation slot is processed; sequence 3, the uppermost magnetic isolation slot is processed; sequence 4 , process the magnetic isolation slot between the bottom magnetic isolation slot and the middle magnetic isolation slot; Sequence 5, finally process the magnetic isolation slot between the uppermost magnetic isolation slot and the middle magnetic isolation slot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com