Tensioning regulating mechanism of steel pipe straightener

The technology of tensioning adjustment and straightening machine is applied in the field of tensioning adjustment mechanism, which can solve the problems of difficulty in guaranteeing the straightening quality of steel pipes, affecting product quality, loosening, etc., and achieves the effects of reasonable design, convenient operation and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

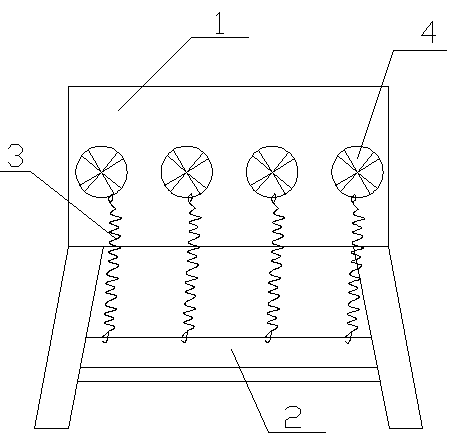

[0010] Such as figure 1 Shown: a tension adjustment mechanism of a steel pipe straightening machine, including a frame 1, a tension adjustment mechanism is fixedly arranged on the frame 1, and the tension adjustment mechanism includes a cross bar 2, a spring 3, wherein the The cross bar 2 is fixedly arranged on the bottom of the frame 1, and one end of each spring 3 is connected with each adjustment plate 4 fixed on the frame 1 for adjusting the straightening wheel, and the other end is fixedly arranged on the On the crossbar 2. Wherein said cross bar 2 is made of an angle steel.

[0011] The beneficial effect of this embodiment is: the design is reasonable and the operation is convenient, and the adjustment disc 4 fixed on the straightening machine is adjusted by the tension of the spring 3, so as to avoid the vibration generated when the straightening machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com