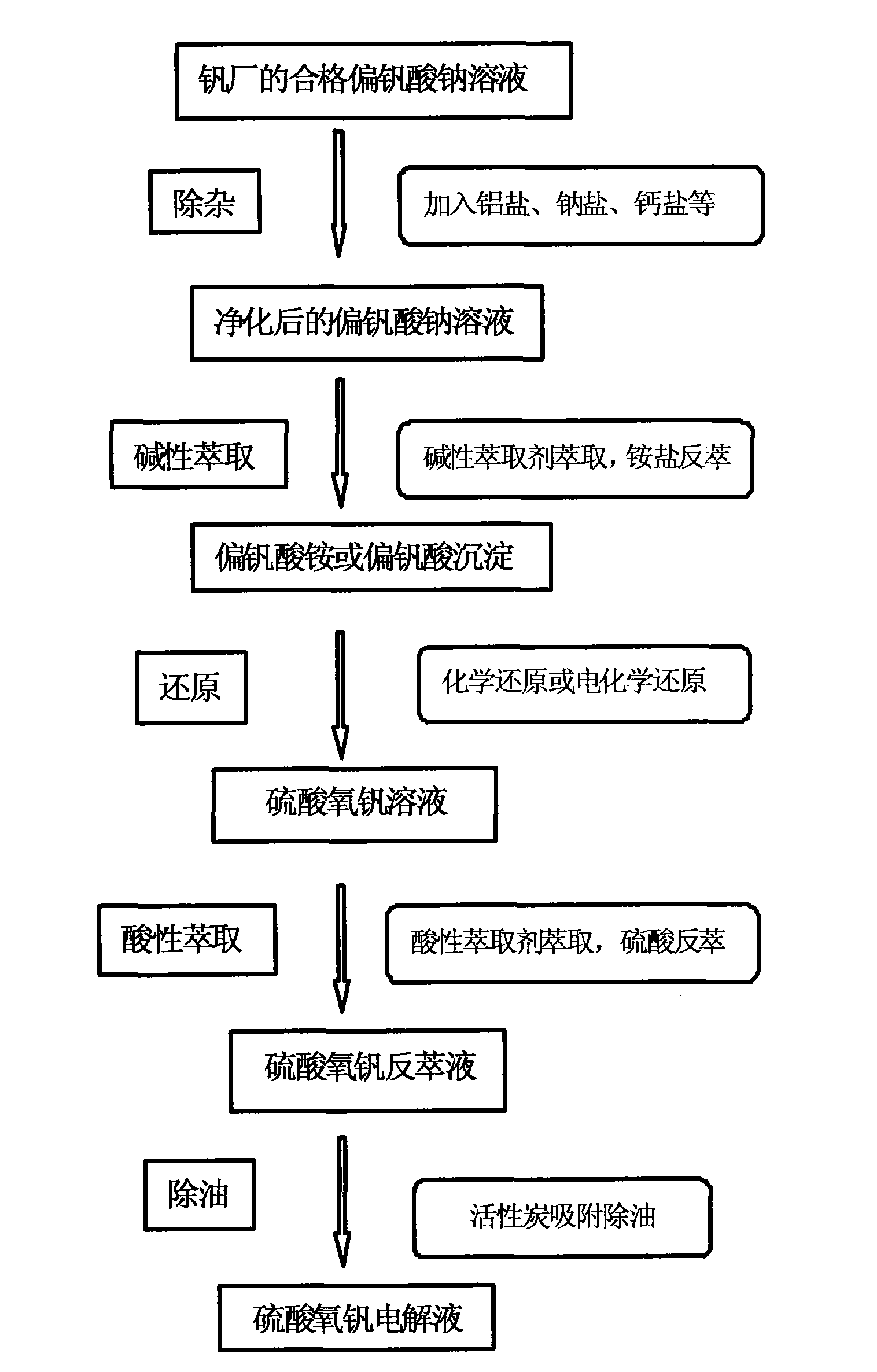

Two-stage extraction preparation method for high-purity vanadyl sulfate solution

A vanadyl sulfate extraction technology, applied in liquid solution solvent extraction, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high impurity content and inclusions in vanadium electrolyte, reduce production costs, and improve product quality. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] In 10 liters of standard vanadium liquid, the concentration of vanadium is 0.4M, and impurities include silicate, chromate, and phosphate, and cations include iron, calcium, magnesium, and manganese ions.

[0022] 1. Remove impurities

[0023] Silicon removal: Take 10 liters of the stock solution, adjust the pH of the stock solution to 9, add aluminum sulfate (according to the ratio of Si:Al=1:1.2), and keep the pH of the stock solution at 9 during stirring for 2 hours. After standing for 12 h, the precipitate was filtered.

[0024] Calcium removal: add sodium carbonate (according to Ca:CO 3 2- =1:1 ratio), adjust the pH of the filtrate to 11, heat to 100 degrees and then cool slowly, let stand for 12h, and filter the precipitate.

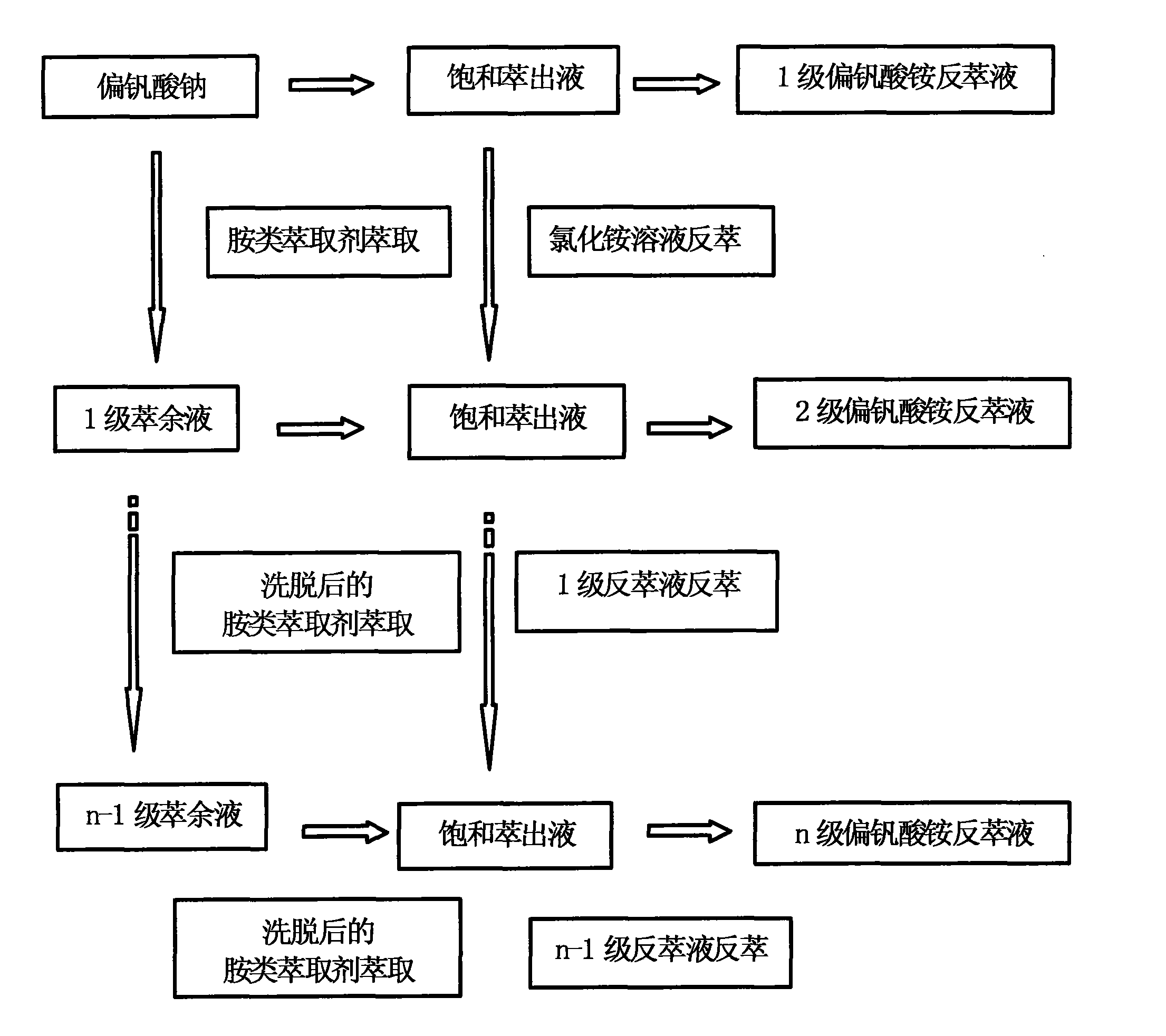

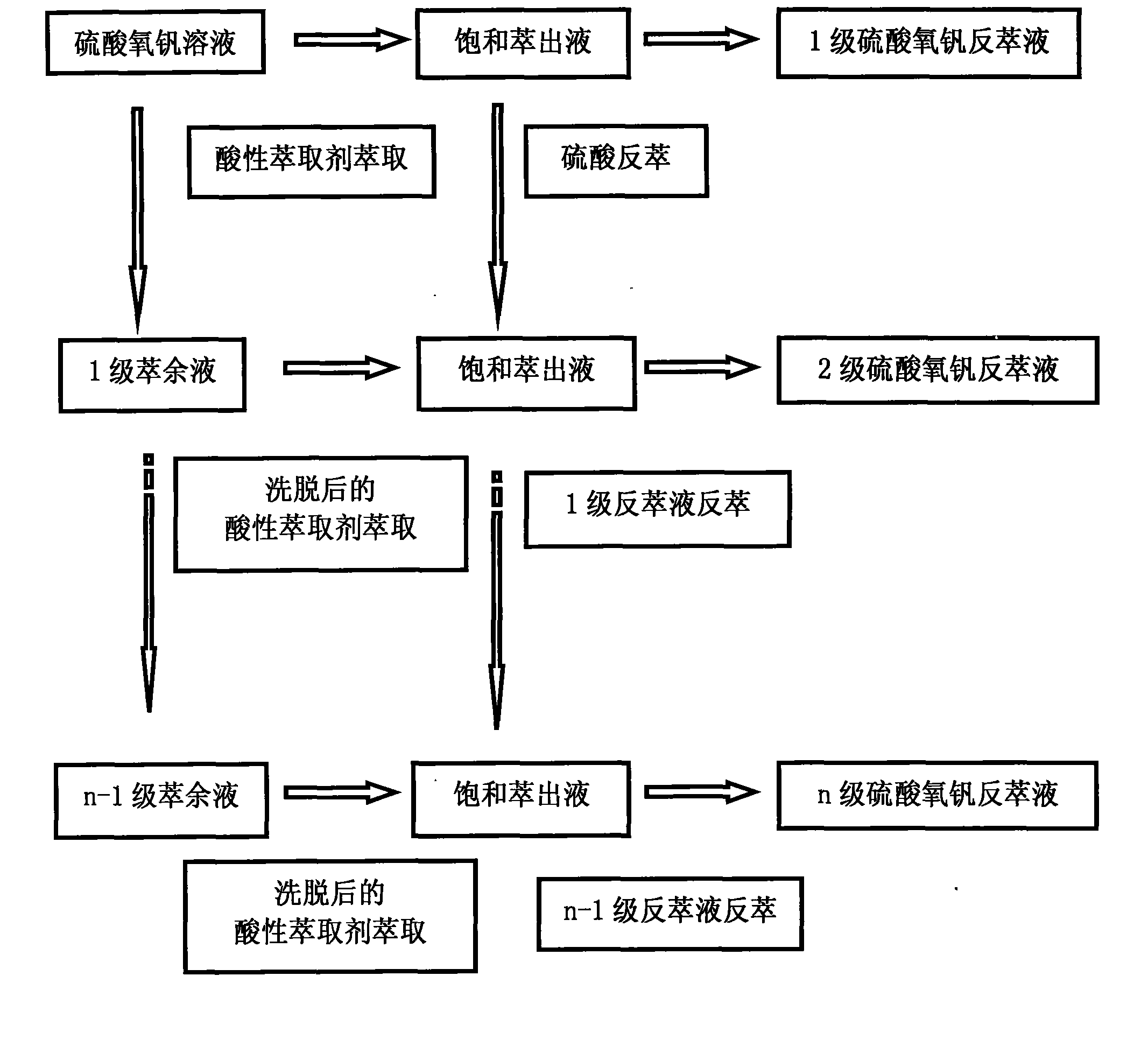

[0025] 2. Alkaline extraction

[0026] 10 liters of vanadium solution is extracted with 2 liters of extractant (the ratio of extractant is Alamin304: kerosene=4: 6), the extraction process time is 20 minutes, and the extract is back-extr...

example 2

[0034] In 10 liters of standard vanadium solution, the concentration of vanadium is 0.6M, and impurities include silicate, chromate, and phosphate, and cations include iron, calcium, magnesium, and manganese ions.

[0035] 1. Remove impurities

[0036] Silicon removal: Take 10 liters of the stock solution, adjust the pH of the stock solution to 9, add aluminum sulfate (according to the ratio of Si:Al=1:1.2), and keep the pH of the stock solution at 9 during stirring for 2 hours. After heating to 100°C, cool slowly, and after standing for 12 hours, filter the precipitate.

[0037] Calcium removal: add sodium carbonate (according to Ca:CO 3 2- =1:1 ratio), adjust the pH of the filtrate to 11, heat to 100 degrees and then cool slowly, let stand for 12h, and filter the precipitate.

[0038] 2. Alkaline extraction

[0039] 10 liters of vanadium solution is extracted with 2 liters of extractant (the ratio of extractant is Alamin304: kerosene=4: 6), the extraction process time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com