Flavor-enhancing lactobacillus rhamnosus

A technology of Lactobacillus rhamnosus and CHCC12697, which is applied in the field of preparing dairy products and can solve problems such as huge costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Example 1: Screening for thermophilic Lactobacillus species with high acetoin levels in acidified boiled milk.

[0088] The selected 176 Lactobacillus strains were examined for their ability to acidify boiled milk at 30°C, 37°C, 40°C and 43°C for about 24 hours. Volatile organic compounds (VOCs) from acidified boiled milk incubated at 37°C were examined directly after fermentation by means of headspace gas chromatography, as described in Example 5. The strain designated CHCC12697 was found to produce high levels of acetoin (135 ppm) and relatively high levels of acetaldehyde (8 ppm) (data not shown). This strain was observed to acidify boiled milk at mesophilic temperatures (30-37°C) as well as at thermophilic temperatures (40-43°C). The strain was also observed to grow to high OD at 40°C and 43°C in MRS broth supplemented with 2% glucose or 2% lactose or 2% fructose or 2% galactose. The strains are not resistant to antibiotics. Partial 16S rRNA gene sequencing showe...

Embodiment 2

[0089] Embodiment 2: the method for preparing yoghurt

[0090] Skim milk (Dan Mselk, Aria) was added with 2% skim milk powder (Aria) and heat treated at 90°C for 20 minutes. This solution was inoculated with a background starter culture, with or without Lactobacillus rhamnosus strain CHCC12697.

[0091] Background starter cultures for yoghurt preparation contained multiple strains of S. thermophilus and L. bulgaricus in frozen direct cast (F-DVS) format at a rate of 0.02%. The amount of L. rhamnosus strain in the F-DVS form described in the Results section was added to the background starter culture. At the time of inoculation, the cell counts of Streptococcus thermophilus strains and Lactobacillus rhamnosus strains were higher than 1x10 10 cfu / g and cell count of Lactobacillus bulgaricus strain above 1x10 8 cfu / g.

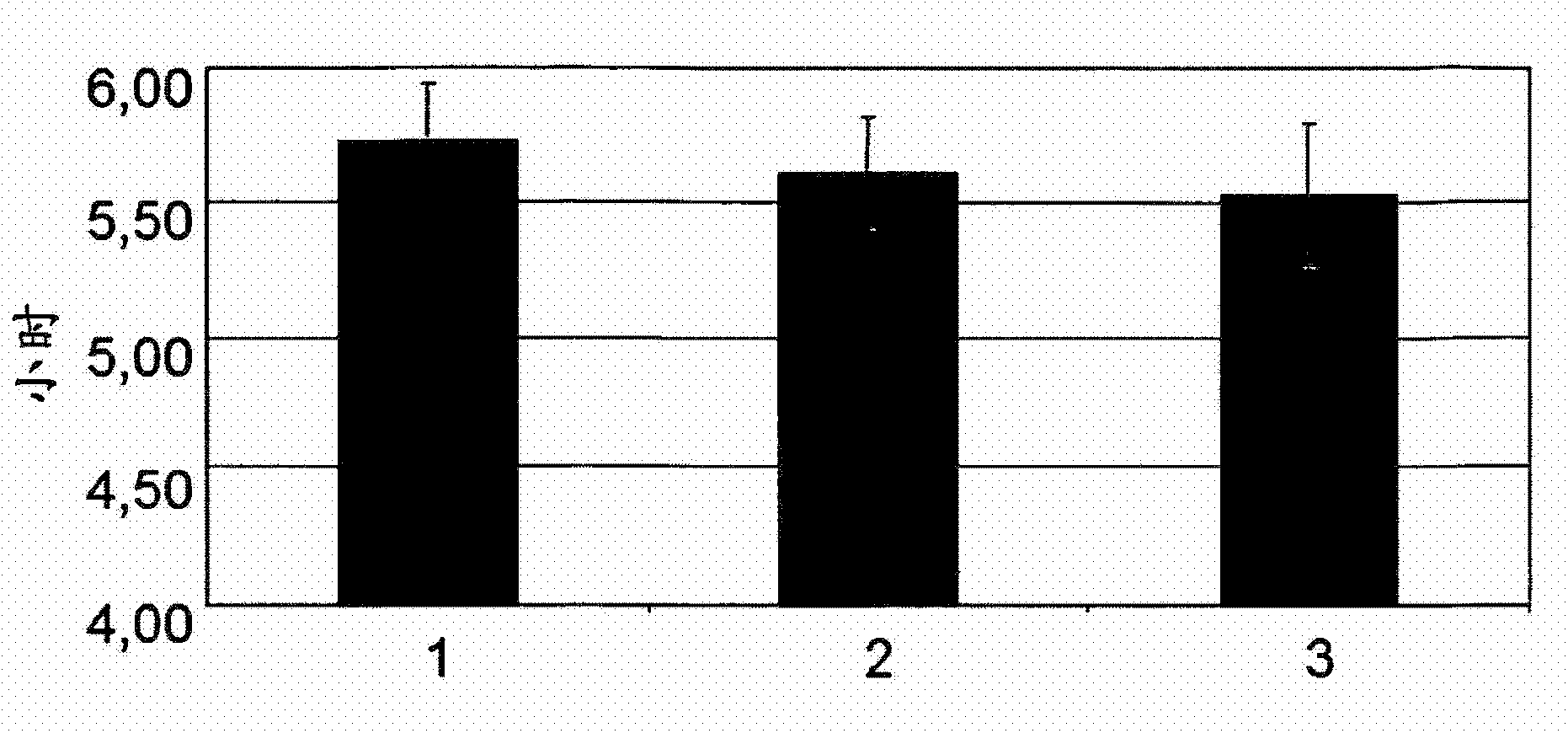

[0092] The inoculated solution was heated to 43°C and fermented to pH 4.55. The time to reach pH 4.55 is shown in figure 1 in the fermentation time. When p...

Embodiment 3

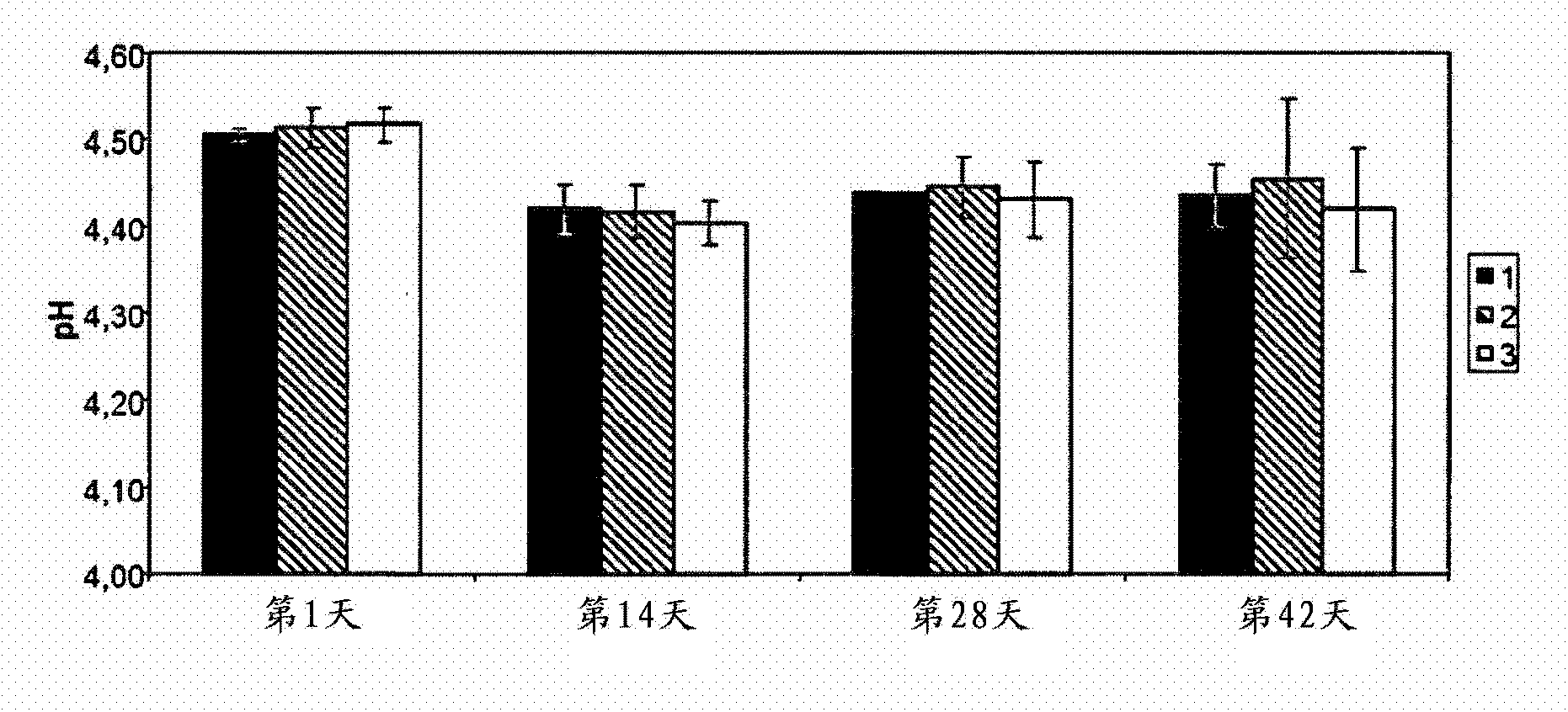

[0093] Example 3: Method of measuring pH evolution

[0094] On the day of analysis (after 1 day, 14 days, 28 days and 42 days in refrigeration), a plastic cup containing yoghurt was removed from the refrigerator and the pH was measured using a pH meter (pHM240, MeterLab). Prior to measurement, the pH meter was calibrated (2-point calibration with 7.00 and 4.01 buffers). As with samples, keep buffers for calibration refrigerated. figure 2 Shows the evolution of pH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com