A reasonable matching method of beam pumping unit and electric motor

A beam pumping unit and matching method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of unreasonable matching of the working characteristics of the pumping unit and the working characteristics of the motor, and achieve convenient and universal sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with accompanying drawing, the present invention will be further described:

[0062] This reasonable matching method of the beam pumping unit and the motor,

[0063] Step 1. Establish a pumping unit database, which is used to call relevant parameters when calculating the motion and power of the pumping unit system.

[0064] The database includes geometric structure dimensions of several models such as conventional machine, different camera, and double donkey head machine. According to the three-dimensional geometric model, the moment of inertia of all moving parts is calculated in PRO / E.

[0065] The database also includes the initial pumping parameters of the matched well: stroke, stroke times, pump hanger, pump diameter, etc.

[0066] The database also includes working condition parameters of tested matched wells: oil pressure, casing pressure, water cut, fluid level, crude oil density, crude oil viscosity.

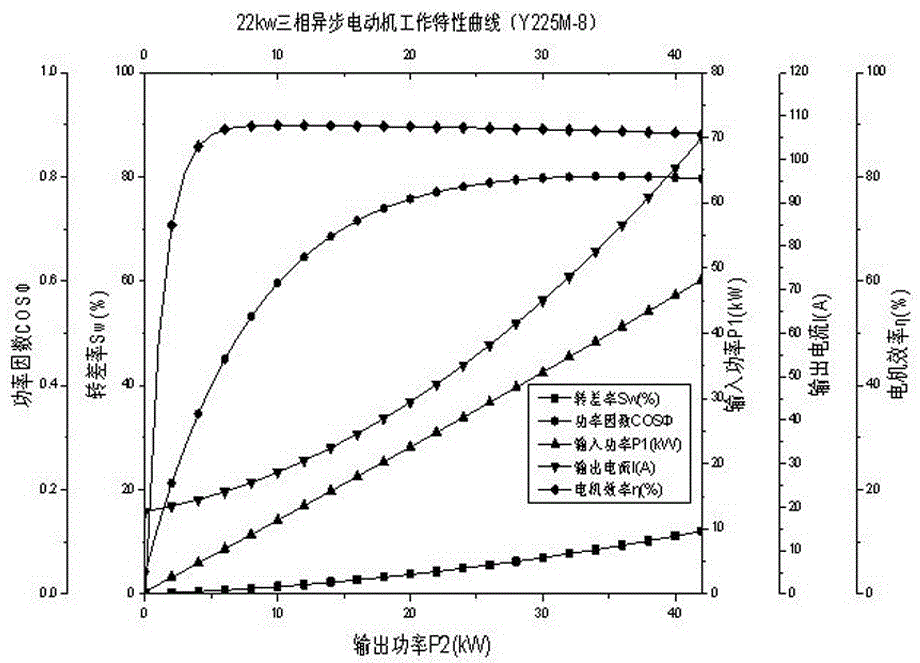

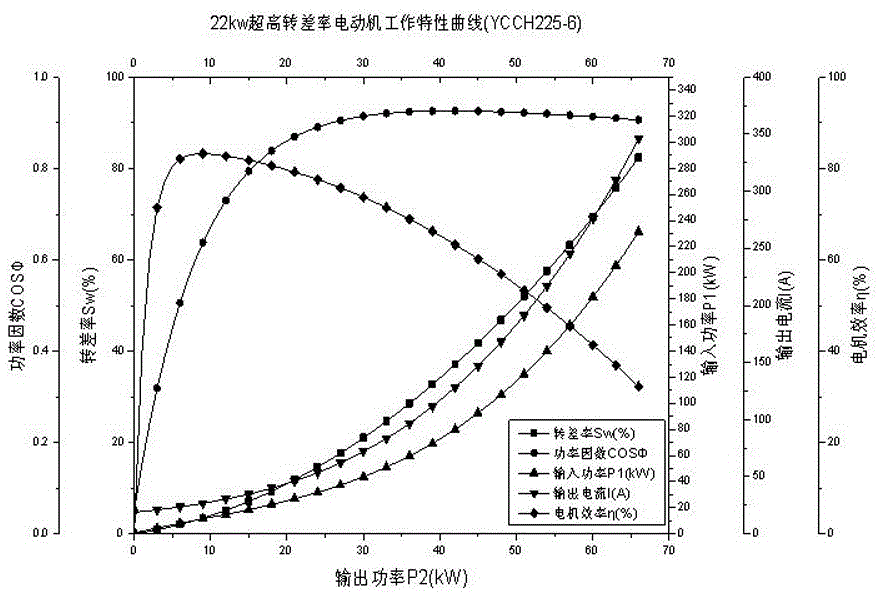

[0067] Step 2: Establish the motor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com