A kind of high-strength composite material optical fiber for long-distance penetrating curved pipes and its preparation method

A technology of curved pipes and composite materials, which is applied in the field of high-strength composite optical fibers and its preparation, can solve the problems of subsea installation and flexible application of optical fiber distributed temperature monitoring systems, inability to traverse curved pipes for long distances, and inability to penetrate long distances. It can save manpower and material resources, good electrical insulation and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

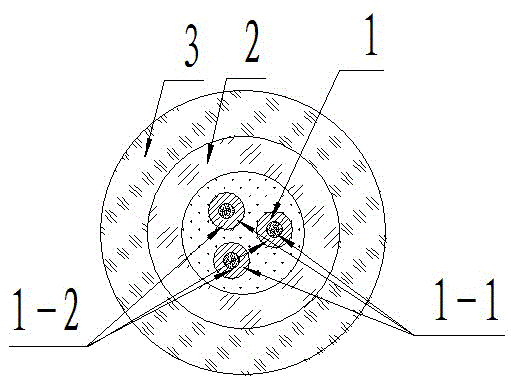

[0030] 1. A high-strength composite optical fiber for long-distance penetration through curved pipes, which includes a stainless steel tube optical fiber unit (1), a high-strength fiber composite material (2) and a coating coated on the outer periphery of the stainless steel tube optical fiber unit (1) The fiber composite material (3) with high elongation at break on the periphery of the high-strength fiber composite material (2), the stainless steel tube optical fiber unit (1) includes a stainless steel tube (1-2) and is wrapped in a stainless steel tube (1-2) The fiber bundle (1-1) inside; the number of the stainless steel tube fiber unit (1) is 1.

[0031] The above-mentioned high-strength fiber composite material (2) is made of carbon fiber or ink fiber pre-impregnated with epoxy resin.

[0032] In the above-mentioned high-strength composite optical fiber for long-distance penetration through curved pipes, the fracture elongation fiber composite material (3) is made of glass...

Embodiment 2

[0043] 1. If image 3 As shown, a high-strength composite optical fiber for long-distance penetration through curved pipes, which includes a stainless steel tube optical fiber unit (1), a high-strength fiber composite material (2) wrapped around the outer periphery of the stainless steel tube optical fiber unit (1) and wrapped A fiber composite material with high elongation at break (3) covering the outer periphery of the high-strength fiber composite material (2), the stainless steel tube optical fiber unit (1) includes a stainless steel tube (1-2) and a stainless steel tube (1-2) ) within the fiber bundle (1-1); the number of the stainless steel tube fiber unit (1) is 3.

[0044] The above-mentioned high-strength fiber composite material (2) is made of silicon carbide fiber or ultra-high-strength polyethylene fiber pre-impregnated with epoxy resin; the above-mentioned high-strength fiber composite material (3) is made of pre-impregnated polyester resin There are polyester a...

Embodiment 3

[0055] 1. A high-strength composite optical fiber for long-distance penetration through curved pipes, which includes a stainless steel tube optical fiber unit (1), a high-strength fiber composite material (2) and a coating coated on the outer periphery of the stainless steel tube optical fiber unit (1) The fiber composite material (3) with high elongation at break on the periphery of the high-strength fiber composite material (2), the stainless steel tube optical fiber unit (1) includes a stainless steel tube (1-2) and is wrapped in a stainless steel tube (1-2) The fiber bundle (1-1) inside; the number of stainless steel tube fiber units (1) is 6.

[0056] The above-mentioned high-strength fiber composite material (2) is made of poly-p-phenylene benzobisoxazole (POB) fiber or polyphthalamide p-phenylene diamide fiber (Kevlar) pre-impregnated with phenolic resin; The above elongation at break fiber composite (3) is made of polybutylene terephthalate fiber (Fibre-L) pre-impregna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com